As the laser engraving industry continues to grow and expand, companies are devising new products and substrates that can be decorated using lasers.

Different types of acrylic are the biggest sellers when it comes to laser engraving, but wood, metal, rubber and even faux leather are growing in popularity.

Dave Johnson, director of operations at Johnson Plastics in Minneapolis, believes that at least three-quarters of the materials used in laser engraving are acrylics or modified acrylics.

When plastics first came out for signs, the majority of them had a core called ABS, which melts under the heat of a laser.

“Companies had to reformulate the sheet stock,” Johnson says. “What it is now is modified acrylic. For acrylic in its pure form, laser is the best. It doesn’t melt. It doesn’t warp. The edges aren’t sticky. The more acrylic in the base, the easier it is to engrave or cut out.”

Duets by Gemini, in Cannon Falls, Minnesota, manufactures substrates that can be used in both laser and rotary engraving. Duets makes plastics with ABS for the rotary engraving market and acrylics for the laser market.

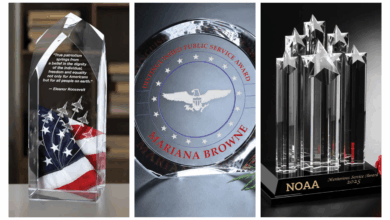

Gary Harder, director of Duets by Gemini, says that he still sees great demand for laser engraving in the sign industry but that awards, trophies and plaques are rising in popularity. Name badges are another great market to get into because many large corporations will go through tens of thousands of badges a year.

“It is a great product for engraving plastic because the perceived value is high but the material cost is low,” Harder says.

Alternatives to metal

Many plastics manufacturers have come up with acrylic products that look like brushed aluminum or stainless steel and “those products go over very well. They are easy to engrave and look like metal and there isn’t an extra process of oxidizing,” Johnson says.

Customers who want to engrave on real aluminum or brass have to apply a real chemical to it afterward to get the letters blackened.

“It is very easy for laser to cut it out instead of sheer cutting metal. The laser beam goes right through the plastic like butter and produces a very high-quality product,” Johnson says.

ADA signage is one of the best segments of the signage industry to get into because most companies need almost an unlimited supply of ADA-compliant signs. More and more sign shops are using lasers to make these signs.

“In the past it was always done by a rotary engraving machine but shops are finding that the laser can cut them out quicker. The only thing it can’t do is drilling holes into the substrate and inserting the beads of acrylic in there, the braille part,” Johnson says.

ADA signs are the most profitable signs to make, he adds. There is a bit more labor involved but what would have been a small $15 sign becomes a $45 one when the braille beads are added.

Many companies are experimenting with laser cutting rubber to make stamps, while others search for personal items, such as mugs, that cost very little to make but are easily engraved.

Even though plastics that look like metals are popular, industrial customers are still interested in metals, like stainless steel, brass and aluminum.

A new product called CerMark, invented by Ferro, comes in liquid, spray or paste. Engravers apply a dab of it on stainless steel or other raw unfinished non-coated metals. When the laser hits it, it puts a permanent black mark on the metal. This is an easier process than traditional rotary engraving, he says. It also looks nicer and allows a customer to include more detail. It is very popular for sign applications and for labeling equipment.

Harder says that he has seen a huge leap in demand for laser engraved stainless steel mugs. The laser engraver sprays CerMark on it, hits it with a laser and then washes off the black, leaving crisp engraved lettering.

“These are very popular, especially with the holidays coming up,” he says. Many companies are trying to get into this market because the mugs are fairly inexpensive to make but with laser engraving on them can be sold for $30 to $40 a mug.

“Ultimately sign shops want to listen to their customers. They are the ones driving the needs. If they want plastic over metal, those options are available. If they want metal, that is available. Using a laser on both is just as easy,” Johnson says.

There isn’t a ton of innovation as far as substrate materials go, but manufacturers have made their mark by adding new color schemes and adding textured finishes on the material as opposed to just a matte or glossy finish.

“That’s where we see the innovation. I’m not sure that’s innovation. Just more options,” he says.

Mike May, COO of JDS Industries in Sioux Falls, S.D., says that plastics are definitely the most popular substrates for laser engraving but since the Great Recession began in 2008, he is seeing more sign shops branch out and use their laser engravers to personalize promotional products, incentives and customer and employee gifts.

Everyone is looking for additional sources of revenue with their existing equipment.

Plastic isn’t used as much in the gifts and incentives market. It is used more for interior signage. Promotional items are made from all kinds of materials, including stainless steel, solid woods, bamboo, aluminum and anything else that lasers well, he says.

JDS Industries is the largest supplier in the world for component parts for anything personalized. It sells awards, trophies, badges, signage, personalized gifts and photo gifts to various retail stores. It has 14 warehouses nationwide with nearly one million square feet of distribution space and more than 13,000 products.

Into Leather

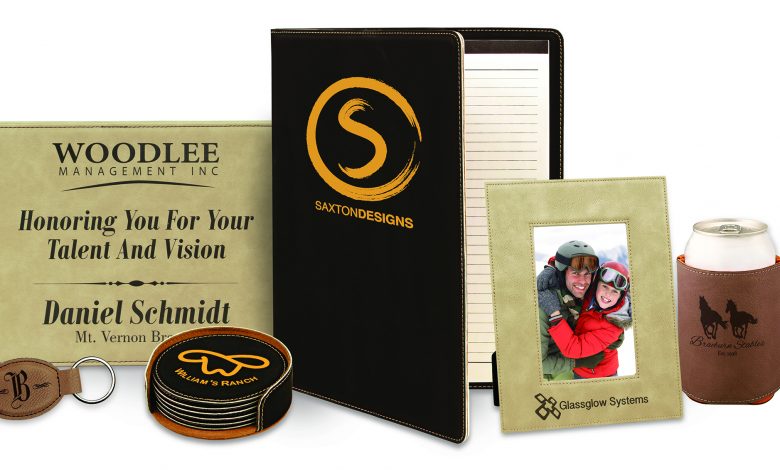

One of JDS Industries’ most popular lines is laserable leatherette.

It is available in dozens of different products, including picture frames, plaques, portfolios, coasters, business card holders and drink holders, such as latte sleeves.

“It is synthetic leather but it looks and feels like leather. The advantage is it is very consistent compared to leather,” May says. “Consistency is important. The whole point of lasering is to focus light to burn material so the surface has to be consistent. The leatherette is affordable; it has a high perceived value, looks great and lasers great. It gives retailers a great opportunity to make a good profit margin.”

Good Old Wood

Wood is also popular because it is easy to engrave.

“Anything out of wood you can personalize is popular. Wood also has the benefit, like acrylic, of low material costs and high perceived value,” Harder says.

Options Are Limitless

Gravotech, Inc. manufactures different substrates that are perfect for laser engraving. Its Gravoply Ultra is “great for indoor, outdoor, rotary, laser (cutting and engraving) and UV printing,” says Terri Bristow, marketing specialist with the Duluth, Ga.-based company. “This material helps increase profits by allowing you to stock only one material type for multiple applications. Since you can create your own custom color combinations, the options are limitless.”

Gravotech also makes a product called Rubbalase, which is perfect for making stamps.

“Not many engraving shops manufacture stamps, which is why it can be an additional revenue stream for some. This material can only be engraved by laser and comes in an odorless option for those that do not like the smell of burning rubber,” Bristow says.

Findlay, Ohio-based Rowmark also manufactures laserable substrates. Its best-selling product is called LaserMax, which is a UV stable micro-surfaced, impact modified acrylic sheet that “engraves beautifully in a single pass,” says Bobbi Payne, customer and technical support specialist at Rowmark. The material is available in numerous colors and also features unique patterns like metallic, woodgrain and marble.

The company’s Metalgraph Plus material is one of Payne’s personal favorites. It is available in four unique metallic finishes and also lasers in a single pass.

“This stunning product line looks like real metal yet it has all the product features and ease of use of plastic,” Payne says.

“Profitability for the laser engraver is contingent on a number of things. Obviously material costs, but fabrications also need to consider design, project layout time, machine time, assembly and clean up. Also contingent in the engraver’s profitability will be their market focus and the margins their market will support,” she adds.