Our company not only had a new building completed, but we remodeled our original building some, and added our direct-to-film (DTF) printer. This is the most we have ever done in just one year, and the year is not over. We started looking at other ways to grow as well!

In January of this year, our builder completed our second building behind us that is only 3,000 square feet. This building holds stock on the second floor and our staff’s break room where they can hang out at lunch together.

The first floor holds a 20′ wide by 62′ long install bay for working on vehicles. The building also houses our 2D/3D laser engravers, our direct-to-film printer, our 54″/64″ vinyl printers, both sublimation printers, and a design office. Having the extra space has been a huge help with vinyl installs as well as larger orders for the other processes we offer in the new building.

DTF connection

Having the DTF process from ColDesi has been a huge game-changer for our company. We can handle so much more work faster than ever before, we’re quicker to teach people to operate, have zero mess, and can train anyone to run the equipment and to heat press.

We rolled the process out slowly starting after two weeks of owning the machine, and we have already produced around 26,000 pieces, which sold for a total of $288,000, an average of $11.07 per piece. Our screen-printing department has run all year and we have produced 24,000 pieces for a total of $316,000, or $13.29 per piece.

So, between both processes, we have a combined total of $604,000, and last year we didn’t have DTF and did $451,000 in screen printing alone. Many will look at how screen printing is still slightly ahead, but that is only due to not having DTF running at the beginning of the year and simply taking our time promoting it.

Since shifting so much work to DTF, we have cut back 60 hours a week on cleaning, emulsifying, and burning screens. We are also not buying anywhere near the amount of supplies we used to for screen printing.

Most customers are switching to DTF for the full-color print and short runs as well, which frees our automated press up for larger runs of only one- and two-color imprints, which takes stress off our staff and makes us much more profitable on the auto and setup times.

The main thing you have to remember with DTF is you have much less setup time and you have more time to heat press orders to get them out faster, so you need to make sure your design team can keep up with how fast the process moves, which is a good problem.

Another factor is the cost to gain full color printing for all size customers. We have spent $20,000 in supplies for the year so far and we still have stock, but let’s say we did not. $20,000 divided into 26,000 pieces produced equals $0.77 per piece produced, and most had a front, left, and back at times.

Screen printing costs alone just in labor from prep to production costs more than that, let alone supplies.

Intelligent expansion

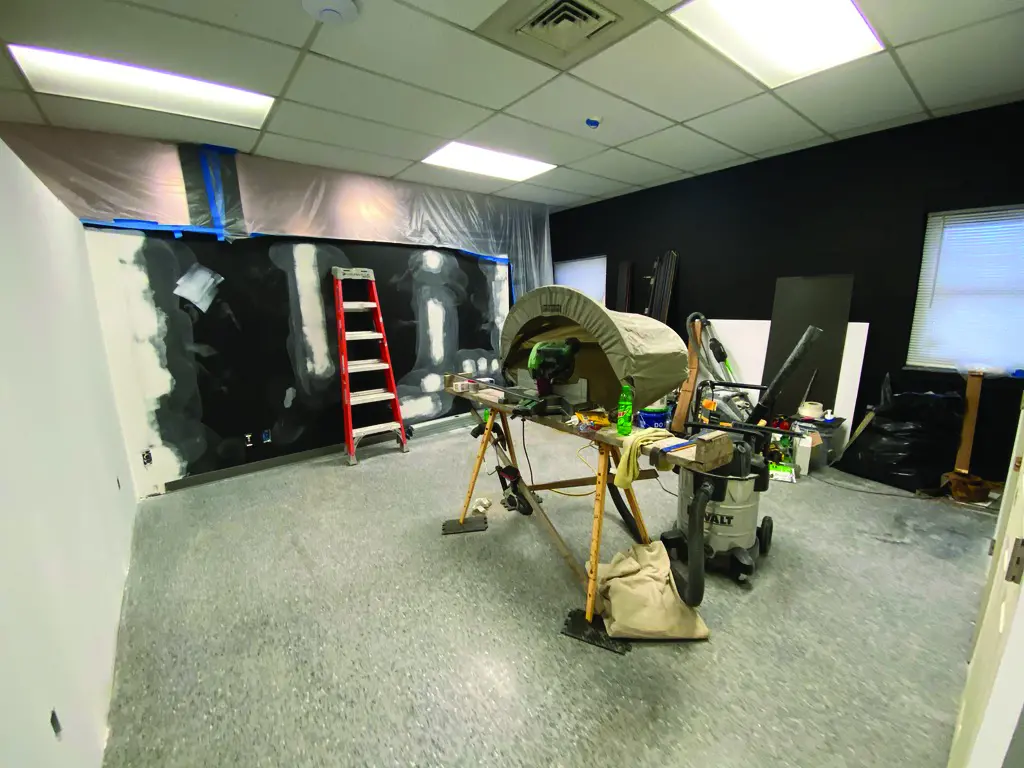

After getting our new building completed and our new DTF machine up and running, we had our builder go into our original building and do a remodel for the customer service team and our embroidery team, along with building out a second showroom.

Last year, our company grew by 34%, which was $750,000 in production, so our customer service team needed more space to work so we could hire more staff. We are now up to six full-time customer service reps, and we are looking to get to ten by the end of next year. This has helped our customers place orders faster and sped up the pick-up times if they stop in to get their orders.

Due to the growth in our first responder sales for uniforms, our embroidery team needed more space for sewing, so we repurposed our old heat press room for not only sewing, but creating room for ship outs as well. Now, the team isn’t tripping over each other to get work done in the same space.

The last piece to be finished in the remodel was the second showroom dedicated to first responders. The space has over $20,000 in samples for them to try on, space to meet with a customer service rep, and two dressing rooms. This space has been a game-changer for customers and more inviting to their needs.

I know what you’re thinking: how did you pull off all of that and keep focused at the same time? One, my wife and I work 80 hours a week, and secondly, we have a great team that cares as much as we do every day and steps up at every chance.

That aside, we have looked to the future and started doing more research. Our goal is to offer more in-house services than any company in the United States. Did you notice something I didn’t say? We aren’t interested in being the largest. We’re focused on our quality, customer service, and turnaround time.

Several promotional companies are struggling to meet production due dates, quality slipping, and shipping companies not getting any better. Over the past five years, all three issues have continued to spike, and we sub out around $500,000 a year in work for orders we do not have the equipment in-house for, so we started researching equipment options.

One is a UV laser that will allow us to laser engrave on the surface of glassware and so much more. With just one machine, and depending on the size of the design, you can average 50 to 72 pieces per hour in production, which is a minimum of 400 pieces per day. Not bad at all! After researching that machine, I went into researching UV printers to be able to print full color onto several different types of materials: pens, golf balls, padfolios, signs, and more. These last two pieces of equipment we’re ordering are going to allow us to take almost 98% of the work we sub out and bring it all in house to keep our team busy and growing, which also allows us to handle more rush orders and turn a profit faster with no middleman holding us up.

In the future, you will see fewer distributors doing this type of work if the manufacturers they’re relying on cannot meet the due dates. This will cause their customers to go elsewhere, and several manufacturers already have sister companies that are going direct to the customers, so this is where you have the advantage if you are willing to do the extra work by bringing the print processes in-house. Yes, it is more work, bigger risk, but also with all of that comes a bigger reward for you and your team! Keep making moves, everybody!