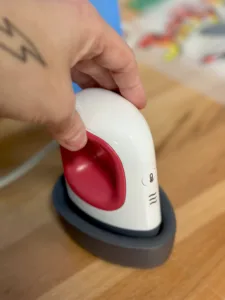

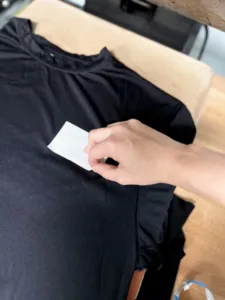

Before we get started, and for purposes of this article, I’ll refer to a heat press as it is defined by wikipedia.org, “A heat press is a machine engineered to imprint a design or graphic on a substrate, such as a t-shirt, with the application of heat and pressure for a preset period of time. While heat presses are often used to apply designs to fabrics, specially designed presses can also be used to imprint designs on mugs, plates, jigsaw puzzles, caps, and other products.”

I’ll ignore those specially designed presses to focus on those we currently have and that I’ve seen most in shops I’ve visited: the traditional flat platen press and the hat press.

Heat principles

After five years in this industry, it’s become clear that heat pressing is a bit controversial. Some see it as a threat to screen printing, but as my good friend Dylan Gilligan from Upstate Merch/Shirt Show always says, “It’s just another tool in the screen printer’s toolbox.” I don’t believe it could or will ever replace screen printing, but it can provide another opportunity to increase and diversify your current offerings.

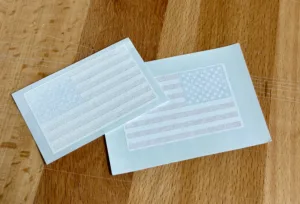

In 1972, the shop I work for was started as Varsity Sport Shop. Beginning with names and numbers on jerseys, heat pressing heat transfer vinyl (HTV) has been a part of our shop for over 50 years now. As our business has grown and the industry has evolved, so have our offerings. We’ve taken to utilizing transfers as strategically as possible:

- It’s allowed us to maintain a more streamlined screen-printing process by keeping outliers off press, such as child/toddler/onesie sizes, sleeves, tags, odd locations like curved around the collar, etc.

- As a small downtown business, we are a shop with size constraints, one of which is currently maxed out with six heads of embroidery. Heat pressing hats with direct-to-film (DTF) transfers and patches – leatherette, woven, embroidered, sublimated, etc. – has alleviated some pressure from our embroidery department.

- We met Candy from Howard Transfers last year, and she taught us about the magic of their options, such as puff, glitter, reflective, hybrid, and glow-in-the-dark screen-print transfers. Because of that amazing information, we’ve been able to increase our material offerings, which basically means we can offerthat stuff, but we don’t have to screen print that stuff.

- As technology becomes more accessible, so have design apps and graphic designers. As I’m sure you know, these things have complicated some facets of our industry, one being the general public’s understanding of a logo vs. a graphic. Heat pressing options have helped us bridge the gap for those customers who would like access to higher color count prints but have lower quantities and/or budgets.

- Despite our best efforts, some substrates have given us trouble on-press. Transfers with a blocker base combined with a single variable of heat (the temperature of the heat-press) vs. multiple on press (flash and dryer) have helped us combat off-gassing and dye migration with finicky fabricssuch as polyester and nylon.

- Like many of our industry friends, we moved into the online store space a hot minute ago. We’ve been on that learning curve with the rest of you. Heat press and transfers have helped us provide more of an on-demand and quick turn model for online stores, saving us overhead and (precious) storage space, as well as lessening the buyout risk for our customers when their store closes.

Despite heat transfer vinyl being around just as long as plastisol for apparel (give or take), it’s often treated as the new kid, which undoubtedly means resistance and controversy. Understandably so. This business can be difficult at times, and we have so much on the line every day that it’s no wonder we are protective of it.

I’ve reached out to several friends who have been in this industry for many years, and the general consensus is that there was a shift not that long ago. Based on those conversations, I’ve been able to pinpoint that the shift occurred when heat pressing became more accessible to the general public, with the increasing availability and ease of use of home cutters and presses.

While first introduced in the early 2000s, the spike in popularity occurred around 2015-2016. I even used a Cricut before I started in this industry. As a mom, it gave me the flexibility to create Pinteresty one-offs in a matter of minutes/hours for my kiddos without the pomp and circumstance of navigating ordering through a shop.

Judge those moms (and me) if you want, but as a shop, it has alleviated a lot of the one offs and sub-minimum screen print orders that previously created bottlenecks. As an industry, I believe it propelled us forward in the heat transfer world, whether we liked it or not, much like that lil’ pandemic caused us to learn all about other hat and shirt blank options. We are an industry that needs to be pushed sometimes, aren’t we? I digress.

Sometimes I’ve found it’s easy to get caught up in day-to-day minutiae of this industry, and I have to give myself a reality check about what our fundamental business purpose is: customer service. Having transfers as an option allows us to keep more business in-house by making our customers’ lives easier.

There’s a reason a majority of Wallyworlds have become what we used to call Super Wallyworlds; they realized the financial benefits of being a one-stop shop for their customers.

Heat pressing has provided us an opportunity to offer a larger scope of services in terms of branding and apparel for our customers. It helps us, as small businesses, stay competitive with the plethora of online options available at our disposal.

As technology evolves, the industry landscape will continue to change; I expect heat pressing options to become more accessible and the hand/feel to become better than it already has. As I said from the get-go, I don’t believe heat pressing and transfers could ever replace screen printing, but if you haven’t already, I recommend considering how it could benefit your customers and business.