Heat transfer is a term I have struggled with for years. When I started in this business almost 30 years ago, heat transfers were thick, labor intensive, and just a general pain in the rear!

You had to pick out the individual letters and line them up straight and centered with a ruler. Then, we had to tell customers to make sure to turn them inside out when they wash them. You know, all the fun things we dealt with in the ‘90s and early 2000s. All that changed when the new vinyl printers and cutters came onto the scene.

Cheesy transfers?

My first experience with this started in Green Bay, Wisconsin. My son and I went to Lambeau Field to check it out. My son is a huge Packers fan, so that was a great day for him. He begged me to buy him a pair of sweatpants. So, I bought him a pair with the Packers G printed on the leg.

When we got home to Nebraska, he wore them every time they came out of the clothes dryer. After about 25 washings, I thought to myself, “That is not screen printing. That is a darn heat transfer. I paid 80 dollars for a pair of heat-transferred sweatpants! That is ridiculous!”

Then I washed them at least three times a week for many more weeks. The logo still looked perfect. It was still bright and vibrant. That is when I knew I had to figure out what this stuff was.

I called our heat transfer supply house and described what I had, and they told me exactly what it was and how to order it. So, we implemented that into our printing business right away. It made printing on double-layer shorts the easiest thing ever. If you have ever screen printed on double-layer shorts, you know what I mean.

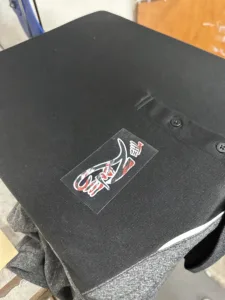

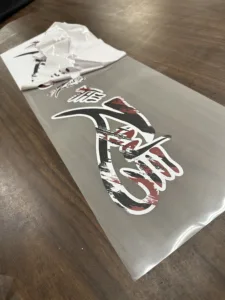

We ordered thousands upon thousands of heat transfers over the next few years. Within the last year, we decided to purchase the machine that makes them, and we have never looked back. It is so nice having full control of the heat transfer part of the business. Not only does it make heat transfers, but we make stickers, banners, and about anything else you can load into the machine.

Heat transfer production tips

Here are my top five principles of heat transfer production:

- Use the correct substrate. This is very important to ensure you get the quality and longevity your customers expect. If you are ordering them from a manufacturer like we did at first, they can help you decide which material is best for the garments you are applying them to. When you manufacture them yourself, take the time to educate yourself on what materials work best for each type of garment. For instance, you can get a bleed blocker material for fabrics that are susceptible to dye migration.

- Use the right heat press. This is very simple and straightforward. Make sure you use a quality press with accurate timers, heat gauges, and pressure gauges. The quality and longevity of heat-transferred products is directly related to those three variables. If one of them is not perfect, then your product will not perform the way your customers expect. Also, make sure you have different size pallets for your machine so you can heat on little garments as well as oversized things.

- Make sure your staff is trained on how to set up the heat press for every job they do. We recommend having a cheat sheet for them right at the press. That way, all they need to know is what material they are heating and follow the chart.

- Packing your finished product. This is pretty self-explanatory, but we want to make sure every product we produce is pulled out of the box by the customer in perfect condition. So, when you are finished heating your garments, make sure to fold them nicely when they are done. Do not ever fold the heat transfer material itself. Let them have plenty of time to cool in the box before you give them to your customer. Following those simple tips can save you from leaving wrinkles and creases in your finished product.

- Finally, you can actually make very inexpensive heat transfers with your laser printer. We only do this in a rush, and when they only want one or two as a quick full-photo printed shirt. You can simply buy the heat transfer material at any Hobby Lobby. Load that into your printer and print it just like anything else. Then you can peel that off of the carrier sheet and heat it onto the garments. Make sure to use a cover sheet when doing this. Craft paper or Teflon paper work the best.

Heat transfer material has come a long way in the last few years. Saying the words heat transfer does not make me automatically think lesser quality anymore. Many of the uniform factories in the world are using heat transfers instead of screen printing now. Take the time to do your research. You can save yourself a lot of work depending on the project you are doing.