Getting Into UV LED Printing

Try these tips for successful item personalization with UV LED printing.

Small-format LED-UV printers are coming down in price and are so versatile they can personalize just about anything that fits in the machine. But, if you’ve never done this type of printing before, how hard is it to get into?

The first step when buying any new piece of equipment is to identify the opportunity that is in front of you, says Mark Stephenson, director of marketing for ColDesi in Tampa, Florida. “These guys are already in the business; they are already making signage; they already have customers,” he adds.

Sign shops should look at what they are already doing and see if there are holes in it. Things they get requests for but they don’t have the ability to accomplish, or their production is too slow and they are looking for ways to improve it on a daily basis.

“You have to make sure you identify the opportunity and that you pick a product that fits with the opportunity,” Stephenson says.

ColDesi Compress LED UV printers are considered mid-format. One is 17.7″ x 24″, which is perfect for foam core, polycarbonate signs, small acrylic signs and metal parking signs. Another is 44″ x 30″, which is excellent for printing real estate signage which is usually printed on corrugated plastic.

The Compress printers are very versatile because they can be used to print things a shop is already printing, like small signage, but because prints come out dry, the end product takes up less space, and a shop doesn’t need drying tables, he adds.

There’s also no weeding or peeling necessary since the machine is direct print. That means a less-skilled workforce can handle the job of positioning materials in the machine.

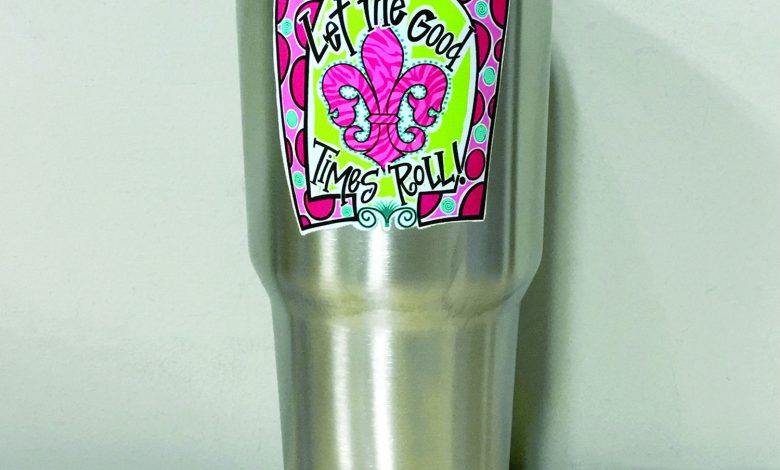

The Compress printers can print on things as much as 11.8 inches deep, so sign shops can add a rotary attachment to print on Yeti mugs, cardboard or completed packages. They can also enter the awards business and print on everything from acrylic cubes to basketballs and Swiss Army knives.

Stephenson recommends selling these additional products to existing customers first. If a company comes to them for wayfinding signage, they can ask if they need any promotional products to announce their new building. Many companies want lots of promotional items with their logo on them to send out as corporate gifts, like coasters, mugs, keychains, USB drives and tiles.

“That’s where the UV LED printers really shine because you can do so many different things,” he says.

Rachel Tindal, art director for LogoJET USA, says that companies looking at UV-LED printers should first consider why they are adding a UV printer. “Is it because they want to replace their existing technology they have used to decorate signs or that they want to expand their capability and do things they are not able to do with their existing technology?” she asks.

These machines can also be used to complement other sign-making techniques made on different types of machinery. It can add a print to something that has been laser-engraved, for instance, or add full-color graphics or texture to a 3D sign.

“Do a combination of signage with full-color graphics plus other methods of decoration. That way they’re keeping their existing methods, but now they are able to offer something they haven’t done before. People will gladly pay more for these types of techniques,” Tindal says.

They also need to think about what their market’s going to be. A UV printer is a huge investment. It isn’t something you can buy, and it will suddenly pay for itself, she says. Shops need a plan for how the machine will be used.

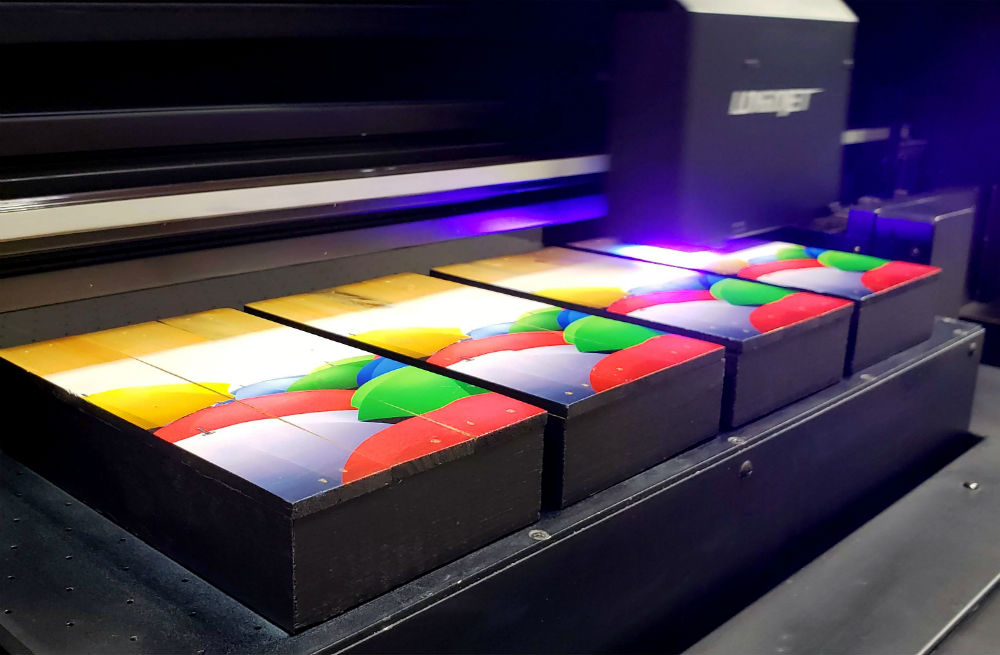

LogoJET’s UV-LED printers can print braille signage, which is a vast market. They also can print white ink, gloss, texture and full color in the same run, without any setup necessary. You just push a button and print. UV printers also allow for odd-shaped signage and have an automatic height sensor. Shops with these printers can do more one-off types of things without having to do a custom setup for each piece, she says, which “saves a ton of manpower.”

Jay Roberts, UV printer product manager at Roland DGA Corp., says that small-format LED-UV printers are “the optimum product to get into any small business.” The company’s VersaUV LEF-12i Desktop UV Flatbed Printer or its VersaUV LEF-200 or LEF-300 Benchtop UV Flatbed Printers have a small footprint so many business startups have purchased them.

“Two things are so prevalent in printing right now,” Roberts says, “one is customization, and the other is personalization.”

He recommends that those interested in buying one of these printers take advantage of industries and markets they are familiar with, like sailing or hockey, and then target those areas.

Customers aren’t successful just because they buy one of these printers. They need to know what they are going to be printing on, what they like to do, what their interests are, and whether they have an existing client base. Many people think that just buying a printer will bring customers to them.

“You have to have a game plan and a product set that fits that game plan. There are so many objects that you can print to, and you can identify with and you can personalize,” Roberts says. But the companies that succeed have a niche market that includes customization and personalization. Many companies will print on anything and everything, but they don’t make much money at it. Companies that are popping up in malls, amusement parks and kiosks are fetching a higher price for some of these same objects because they offer personalization.

Anytime you can add personalization or customization to an item, it becomes unique.

“You can use the same type of product set, but you are identifying an end-user as your target rather than a mass-produced product,” Roberts adds.

Companies are printing photos on canvas, Frisbees, dog bowls and hockey pucks.

“The niche production is far more valuable. The machines themselves are not geared to mass production. If you want mass production, buy a $1 million machine and prepare for volume, so your profits are 10% to 15% margins whereas something like this is 30% to 50% margins or more,” he says.

It takes less than a day to install a new UV-LED printer, and they are simple to use. Roland’s UV-LED printers also come with intuitive software, and they aren’t overly expensive, coming in at less than $20,000.

Getting a return on investment on a new machine will be more difficult for people just entering the printing business for the first time because they are not entering the market with a game plan or existing clients.

“You will have to go find products, go out and market products,” he says. Many businesses start as retail and move to office/warehouse because they increase their production so much they need additional storage for supplies. Others start out as retail and migrate to the Internet.

Shop owners are only limited by their own creativity when it comes to the items they can print on, Roberts says.

Companies that have only done screen printing or laser graphics in the past will need to bring someone on board with more graphics background, LogoJET’s Tindal says. “There is definitely a learning curve when it comes to UV printing because of the RIP software and all of the color management that goes into that. You will want someone with a graphics background who can create files in the correct way.”

She recommends that shops hire someone with a working knowledge of design programs such as Photoshop or Illustrator.

Maintenance is also very important when purchasing a UV-LED printer. They are low maintenance, but they do require a little maintenance very often, she says. Shops won’t have a problem with their machines if they keep up with their daily head cleanings and nozzle checks and weekly maintenance.

“It’s only like 10 to 15 minutes of maintenance, but if you neglect that it will start having problems,” Tindal says.

She adds that sign shops should research what their primary product offering is going to be and find the machine that best suits that. Some printers do everything, and a specific sign shop may not need that. They also should buy a machine that comes with extensive customer support via phone, YouTube videos and onsite instruction.

“You want someone who is going to be responsive because this is a new thing,” Tindal says. “It is not going to pop out of the box and you never have another question or need. You will need ongoing support from wherever you get your UV printer.”