Getting into the Wide-Format Printing Business

Suppliers offer advice and tips for opening or expanding a wide format business.

Perhaps you own a small print shop and are looking to expand your services, or you are new to the market and are considering buying an existing wide-format business or starting one from the ground floor up. Whatever your situation, there are a number of points to consider and a lot of homework that needs to be done before putting up your “Open for Business” sign.

Buying an existing shop requires less work in start-up costs and finding a location. Starting a wide-format business from scratch will take more time, but it could allow you more flexibility in choosing a location, equipment and the work you want to produce.

What Goes into a Business Plan?

The first thing you need to do is create a business plan. This plan should have an ROI (return on investment) model. Create a spreadsheet and a letter explaining the new business plan. Include actual numbers with a timeline that shows how, in time, the business will start to make money. The business plan should review the basics such as payroll, rent, overhead (electric, heat, etc.), marketing, capitol (equipment), future expansion, expected material costs, vehicles, and anything else needed to make the business successful.

Dave Conrad, director of sales and marketing, Mutoh America, Phoenix, Arizona says the business plan should look at basics like market strategy, competitive analysis, a SWOT analysis (strengths, weaknesses, opportunities, and threats), short- and long-term goals and what you will do to attain them.

“This is your blueprint for the business,” Conrad says. “It is important to understand where you are, what you have and what opportunities you have to grow to where you want to be. A well thought out business plan is your launch pad for the business.”

Should You Buy or Lease Your Location?

“Cash is king, and unless you have it growing on trees, it is a wise decision to rent your facility to get started,” says Conrad. “So many factors will come into play you may not have control over and not having to worry about common area maintenance and the day-to-day upkeep of a property will free you up to focus on your business and growing it.”

Javier Mahmoud, vice president of sales and marketing at CET Color, Atlanta, Georgia, declares that depending on cash flow, if you can buy a brick and mortar location … buy.

Who Should You Hire?

Conrad suggests hiring people with knowledge of this business and marketplace. “For the production floor you don’t want to spend months training and creating waste, upsetting customers and backing up your workflow. Be sure the operators are well-trained and can hit the ground running in order to get things off the ground early and fast. The face of your business and the product you produce should be of utmost importance. You only get one chance to make a first impression, so hire wisely.”

Should You Buy or Lease Your Equipment?

“Because equipment tends to go down in value over time, most people lease. Unless you’re a not-for-profit organization, most shops will lease,” notes Mahmoud.

Michael Maxwell, senior manager, Mimaki USA, Suwanee, Georgia, says they see leasing as the preferred method of financing because it enables customers to protect their cash, overcome budget limitations and acquire the right printing equipment for existing jobs as well as future growth.

“Mimaki Financial Services offers affordable monthly payment plans that can be customized to meet almost any budgeting needs,” Maxwell says. “A comprehensive online Resource Center provides the tools necessary for pre-approval, credit decisions, document preparation and contract commencement. Customers will know within hours-rather than days-of their credit approval status,” he explains.

Daniel Valade, product manager, color products and cutters at Roland DGA, Irvine, California, points out that most people get started with a five-year equipment lease. “The decision to lease or buy typically depends upon a number of factors, however, including the buyer’s available funds and financial situation. It should be noted that when it comes to leasing, some leasing companies will work with customers so they can upgrade their equipment before the current lease is up. This can be beneficial if the leasee outgrows his or her current equipment, requiring machines that allow for increased productivity or greater versatility.”

Your First Printer and Initial Output Expectations

Maxwell believes it’s important to find out what your target applications are before discussing an entry point. “Different technologies serve an array of applications-what suits one may not suit another; getting a good handle on target applications, production volumes and a growth forecast is necessary,” he says. “Will the primary applications be indoor or outdoor? Signs and banners? Soft signage? Rigid graphics or printing on objects? What’s the minimum width required? What are the projected volumes in 3, 6, 12 months and beyond?”

Conrad notes its best to buy for next year. “If you are setting up a sign shop to print banners and displays, but know you’ll be growing into vehicle wraps a year from now, don’t skimp on the 54-inch printer when you really need a 64-inch wide printer. Stepping over nickels to pick up pennies is not a good habit to get into. If you have the ability to finance with a good program or if you have the extra capital, be sure to invest in the equipment you need now that will also handle expected output demands over the next year or three so you are not struggling to keep up with client projects,” he explains.

Valade says that when purchasing your first printer, you should consider who your customers will be as well as your output requirements. “In the case of an existing business that’s expanding, rather than just starting up, additional factors should be considered. If a print service provider already has clients, it’s important to think about how quickly your printer purchase will help you ramp up production and/or expand your product offerings. Conversely, if we’re talking about a startup shop, productivity needs may not be as urgent. In both cases, however, there are fundamental factors that buyers should take into consideration, including printer width, speed, cost of operation, reliability, durability, and ease of use. You’ll want to purchase a quality printer that’s ideal for the products/services you want to provide and will serve your needs as your company grows.”

What Types of Printers Should You Look at and Why?

Conrad says depending on the type of business and the markets you plan to serve, you may need to look at a variety of printers with a variety of ink types. “UV-curable inks for specialty and promotional printing and package design, eco solvent inks for outdoor signs, banners and wraps, dye sublimation inks for t-shirt or apparel and home décor-all of these are options that you need to evaluate to make the right choice for your business. Maybe you can use the eco solvent printer for your signs, banners, wraps, displays as well as vinyl transfer for your T-shirts or apparel business until you grow into another separate dye sublimation printer in the future? A UV-LED hybrid can accommodate your rigid and your roll media for indoor signs and packaging prototypes until you can afford a true flatbed to designate strictly to heavy production runs. All of these are factors you need to address.”

Maxwell points out that the type of ink (water-based/aqueous, eco-solvent/solvent, UV cure, latex, etc.) and platform (roll-fed, tabletop or flatbed) is determined by the types of applications to be produced. “There is a wide array of equipment to suit just about any application in accessible price ranges. For a roll-to-roll printer, eco-solvent is a good first choice because it is versatile in application (indoor or outdoor use), can print onto hundreds of media types, and can be run in an office environment. If a flatbed is the choice, UV-cure technology in a dedicated flatbed platform (not a hybrid) would be our recommendation. Entry-level dye sublimation printers are also available for transfer applications such as short-run textiles (soft signage, fashion designs, etc.) or transfer to hard surfaces (awards, promotional items, etc.).”

“If you don’t already have a roll-to-roll type printer, invest in a hybrid. This will satisfy both flat goods (substrates) as well as roll printing such as banners,” explains Mahmoud.

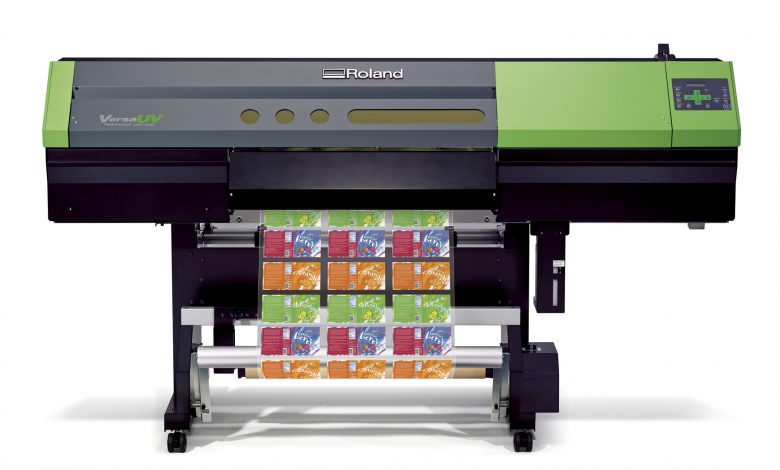

“This will depend upon the type of products/services you want to offer. Do you want to specialize in unique applications, or will you need a printer that can handle a wide variety of applications,” notes Valade. “For a typical startup sign shop, an affordable, reliable eco-solvent printer, such as Roland’s value-packed VersaEXPRESS RF-640, or an equally affordable TrueVIS SG series printer/cutter, will cover the applications currently in highest demand (i.e., signage, banners, POP, decals, labels, vehicle graphics). For people looking to do more unique applications or print to unusual substrates, a quality UV printer, such as those offered within Roland’s VersaUV series, will allow you to print and customize a greater variety of items and print directly onto those objects.”

Valade adds that customization is a huge growth market, and UV printing is leading the way. “With sublimation being another high-growth market, buyers may also want to consider purchasing a quality dye-sublimation printer, like a Roland Texart RT-640, to decorate soft signage, apparel, hard goods with vibrant, eye-catching graphics.”

What Finishing Equipment is Needed?

“You will need a laminator for producing outdoor durable graphics. If you’ll be offering dye-sublimation or heat transfer products/services for creating custom apparel, you’ll need a heat press,” states Valade. “For those who will be UV printing onto rigid or semi-rigid substrates, a CNC router or digital table cutter will help you stand out from the competition by making custom shapes out of the substrate itself.”

“Eco-solvent printers pair up nicely with cold or heat-assist roll laminators for car wraps, mounting and other simple finishing applications,” explains Conrad.

“Most folks have a laminator, a flatbed cutter and some form of stitching option,” says Mahmoud.

When Can You Expect to Make a Profit?

Having a realistic idea of when your new business will make a profit is important. Conrad says a big part of your business planning should look at your break-even point and beyond. “Don’t set your plan to strict goals since your business will change and evolve as you go. Be diligent enough to stick to your plan but flexible enough to react to new market opportunities for increased growth or market penetration.”

Maxwell says that there’s great variance and too many components to provide a comprehensive answer. Location (overhead costs), labor rates, financing, machine and ink type, consumables, software, media, finishing, etc., can affect production costs to varying degrees. “Low cost-of-entry doesn’t always translate into better value because of hidden consumables, service or other printer-related expenses,” he says.

Maxwell adds that “Once a printer/ink type is determined, we recommend preparing an ROI that takes into consideration monthly costs for equipment, labor and overhead, and calculate that to return a ‘cost-per-day’ to run. Then determine a realistic ‘sellable-per-day’ square footage rate from that data, to get a good idea of production needs, costs and return. This is a highly simplistic model but it will help start the conversation about how much is needed to sell in order to achieve a good ROI. Printer manufacturers and experienced dealers can be very helpful in developing an ROI expectation based on an individual business.”

Getting Started Factoids:

- What is the Estimated Cost of Entry?

“In most cases, a shop can get started with about a $50,000 investment in equipment,” Valade notes. That would include a printer/cutter (or a printer and stand-alone cutter), a laminator, a heat press (for dye-sublimation applications) and any other required hardware,” he adds.

Conrad says you can get a 54″ or 64″ printer, laminator, RIP software, startup sign materials like vinyl and banner and laminate, your PC/monitor and ink and materials for under $40-50k. “If you are looking at high production printers with better features like dual print heads, faster print speeds, wider print widths or even dye sublimation where you may need other heat presses or calendar devices or steamers, that can run the cost up quickly.”

Mahmoud reports you can get a hybrid UV-curing printer for about $55,000.

- What are the Basic Equipment Needs?

“Remember input, throughput, output and finishing. You’ll need a PC with a heavy-duty processor for ripping files. You’ll need a good RIP to process the files and manage your workflow. You’ll need a reliable printer to handle the workload you plan to send it. You will want a standalone cutter for all your cut jobs, do not get a print/cut all in one. The only time that makes sense is if you physically do not have space for a printer and a cutter. You’ll also need a laminator to finish the work as well as a nice multi-function worktable, maybe a tabletop trimmer and some straight edges. That will get you started,” Conrad explains.

- How Much Total Space is Required?

Valade says that this will depend upon a number of factors, including the square footage needed for equipment and workspace, space required for finishing and design, storage space for media and other supplies, etc.

“As much as you need to run an effective and productive workflow. This will depend on your equipment requirement and the types of applications you are producing. Give yourself plenty of space to work around the printer, cutter, laminator and table,” says Conrad.

Maxwell reports that large-format printing equipment is available in a wide range of sizes and shapes. “Though there is no strict rule,” he says. “The generally accepted range described as ‘large-format’ falls between 24″ and 96″ wide. For roll-based printers, 54″ and 64″ printers are the most popular sizes. Room for the printer, a computer and software to drive it, plus space to store rolls or sheets of media will be required. A finishing area may also be needed for trimming, laminating, grommeting, etc.”

- How Much Time is Needed to Become Proficient?

“You best be proficient within the first three months,” Mohmoud suggests. Conrad says everyone will learn at their own pace. “Prior experience will obviously make a difference. Nothing beats doing. Repetition will make the learning process much shorter.”

Maxwell reports that most printers can be up and running within hours of installation, and a basic operation tutorial should be provided before the installer leaves the customers’ facility. “Shops should use all the tools available to learn about large format color printing available from their dealer, printer manufacturer or software vendor, or from industry organizations such as the International Sign Association (www.signs.org) or the Specialty Graphic Imaging Association (www.sgia.org). Most shops can be up and running pretty quickly-inside of a few weeks-if they’re producing relatively simple signage. Mastering more complex signs may take more practice, as shops begin to learn the art and science of color profiling. Knowledge of the content-generating software (e.g. Adobe Illustrator, InDesign, etc.) is very helpful,” he concludes.