Spend any amount of time using a laser to personalize items, and you’ll start to have questions. When it happens to our customers, they’ll often reach out to the JDS Fabrication Department experts. Below are their time-tested answers to some frequently asked questions.

How do you clean your lasers?

Some laser manufacturers sell specific lens cleaners, and there are some generic brands out there for regular lens cleaning. We apply them with Q-tips in a light circular motion on the lenses and mirrors. Your laser’s manual should have a section on cleaning your specific machine, from the lenses to the bed to the entire machine itself.

What do you use to remove the residue left behind after laser engraving? Does it need to be diluted or rinsed off after using?

What do you use to remove the residue left behind after laser engraving? Does it need to be diluted or rinsed off after using?

We use LA Awesome on our Polar Camel drinkware, silicone products, and leatherette products. We do not dilute the cleaner and use it right out of the bottle with a microfiber rag. For faster cleaning on large runs, try stacking multiple cups as they come out of the laser, spraying them, and letting them sit for just a minute or so as the LA runs down. You may want to use gloves and run the item under water after removing the residue. For leatherette that lasers to a metallic color, it’s best first to spray the LA Awesome into your microfiber rag and then clean in circular motions towards your engraving.

Is there a quick way to know what color is underneath Laserable Leatherette? How can I remove enough, but not too much, of the top layer?

Our leatherette line is a non-toxic manufactured material. If an item has stitching, an easy way to determine what color is underneath is to look at the stitching’s color. If it’s the same or black, it will be black through the core. The leatherette that lasers to a metallic color will have either gold or silver string. The metallic layer is thin. If you use too much power, you’ll burn through it and into the black that is underneath. You want to take off the surface—don’t burn it!

Here are a few tips when lasering leatherette:

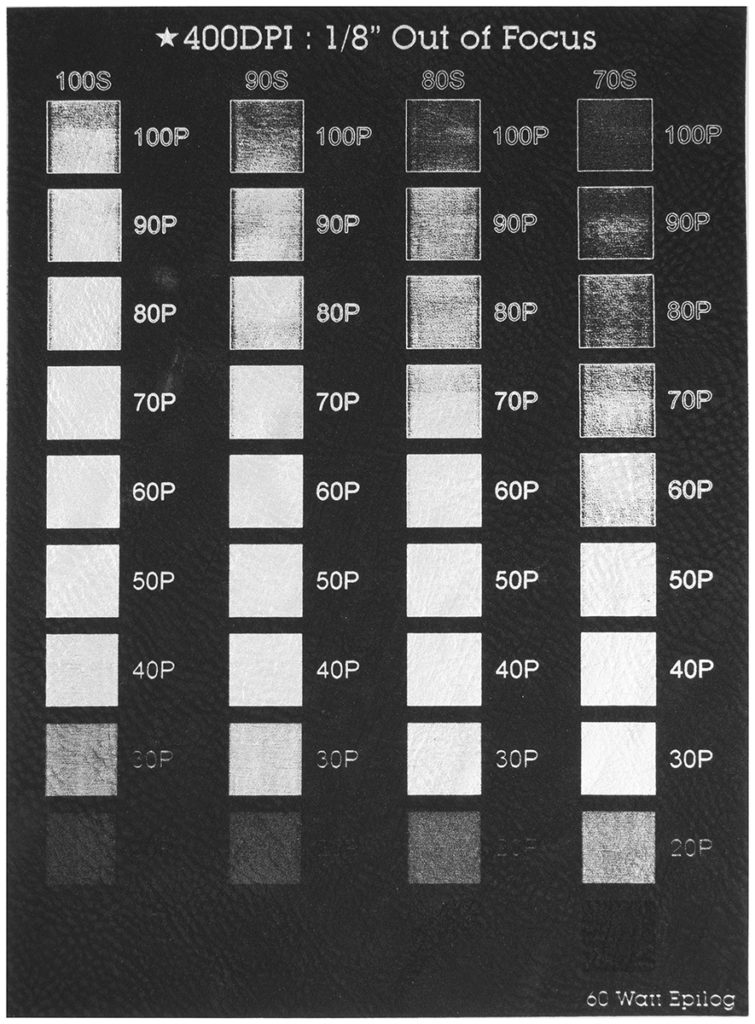

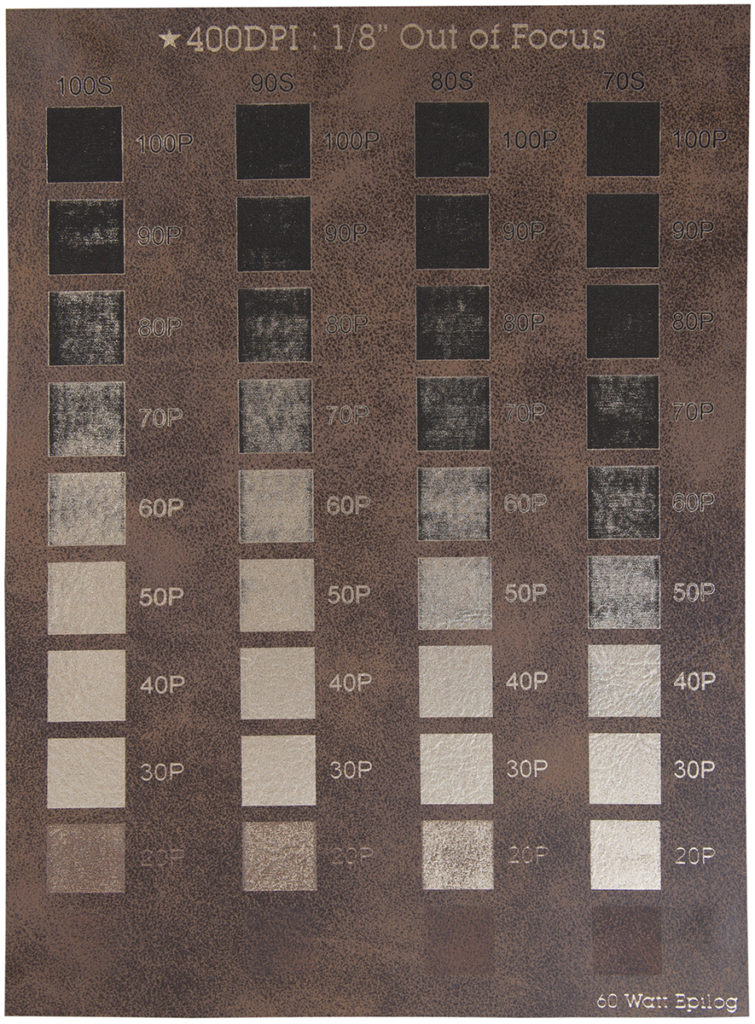

Dropping your bed down a few clicks away from your laser head will help spread out the laser beam for a more even and consistent finish. We usually take leatherette, silicone, and bamboo 1/8-inch out of focus for more consistent finishes.

If the artwork includes super-fine details, it is best to use standard focus and adjust the power and speed settings accordingly.

If you’re lasering to a metallic color, set your DPI to 400. It’s a good idea to test on sheet stock to help zone in your specific laser’s settings. Find a test grid working file and how-to instructions on our website by clicking on the “Instructions” button located under any of our Leatherette products. When the test grid is complete, you’ll be able to see which power and speed settings deliver the best results on your machine.

Watch this video to learn more.

What can I do when lasering a white tumbler and a yellow film develops on the portion that isn’t engraved?

White can leave a yellow film when you use too much heat on your cup. Backing off your power or speeding up your laser can help.

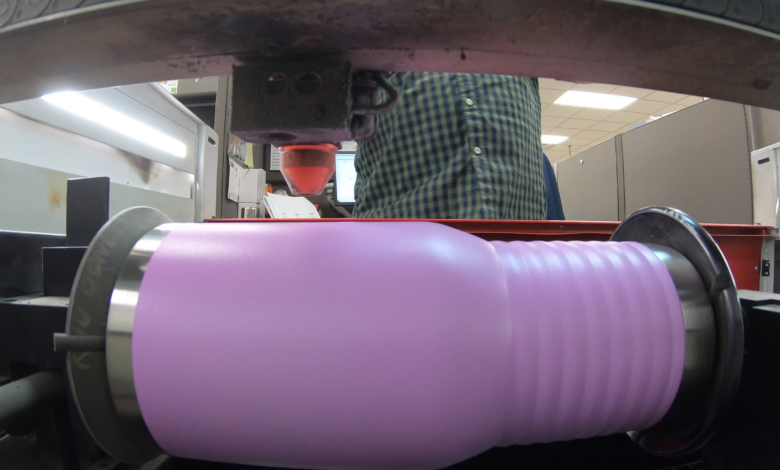

Sometimes, water bottles will slip (not rotating at the same rate) when using the rotary tool. Do you weigh bottles to hold them onto the rollers? Any other tips?

Do not add extra weight. Flip the water bottle on wheel-based rotaries as the lip for lids doesn’t allow for the smooth turning of the bottle, and you’re unable to clip it. Having your wheels spaced about 6-7″ apart will give it a good base to spin on. Tension-based rotaries are set up the same as usual, with leveling needed for best results.

If engraving a Polar Camel water bottle, mark the bottle where you want the front to be. This is a helpful way to center your artwork before removing your lids to laser them.

Can I engrave drinkware if I don’t have a rotary attachment?

Yes, you can do our cups and water bottles on a stationary bed, but you will be limited to a smaller area for your artwork. Ensuring it is level and not able to move is essential.

How do I set up my artwork to engrave items with varying circumferences like a pint glass?

Center-Center engraving is a quick way for easy art placement and engraving. You do not need to have the circumference of the item you’re engraving. You can define the center of your artwork directly on your cup. Check your laser’s manual for the quickest way to do this and what you need to have checked on your laser and properties menu.

How can I reduce the amount of edge char when cutting MDF paneling?

Use multiple passes. If you’re trying to cut MDF with only one pass, it will get too hot and burn.

What’s the best way to engrave items with a base I can’t remove?

Our advice is to build a platform that is around 3″ tall. It will elevate the item and allow you to hang the base off the edge of the platform.

If you have a different laser engraving question, reach out to the experts in our Fabrication Department. Email art@jdsindustries.com or calling 855-537-2228. The new JDS Laser Group on Facebook is another resource for our customers to find answers to their questions.