Flexible LED Tube Products

LED lighting manufacturers now offer a plethora of products that help preserve the unique look of neon.

“Is that neon?” I ask my wife and friends during lunch, pointing to some lettering on the wall of the restaurant. They look back at me with some bewilderment, and about half say yes and half say no. Sensing that it was a trick question, my wife studied the sign in some detail before answering “Yes.” I spend the next 10 minutes studying it.

I, like many of you, embarrass my friends and family by scrutinizing signage up close, running my finger along an edge, studying the lighting, taking multiple pictures. I learned this annoying habit from my father, who no doubt learned it from his father.

Turns out it was not neon, but a “flex” LED tube product. I knew that before I asked, but I was curious what “normal,” non-sign industry folks would say. Are these flex products a viable replacement for traditional neon signage applications? In a word, yes. And not only because they look similar. Flex products are the best of both worlds-you get the many benefits of LED technology, but with the “look and feel” of neon.

Let’s take a look at this broad category of “flex” LED tube products: what are they, how they’re being used in the industry, how they’re similar to and different from neon, and where they’re going. Is this something your shop should offer?

Flex Definition

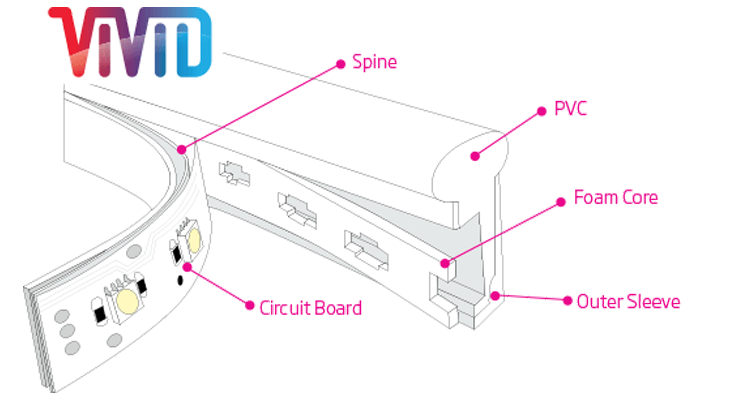

“Flex” is a broad term to define the category of products where flexible LED circuit boards or tapes are mounted with 20-40 small LEDs per foot with a diffusing material such as PVC, silicone, or plastic.

Most flex products are designed in a reasonably similar fashion. The tight pitch of the LEDs and the diffusion materials hide individual points of light. They can be easily handled and manipulated, even when turned on, when they are slightly warm to the touch.

Notable exceptions to this basic design are Current by GE’s Tetra Contour product and INCISEON, two-time winner of the ISA Product Innovation award.

As is common with an emerging product category, there is a lot of variation from brand to brand and product to product; and the technology is advancing quickly to cater to the needs of the sign industry. Flex LED products have seen the most success so far in the sign industry as border tubing and architectural accents. But this is beginning to change as more traditional exposed-neon type applications are in play for flex products.

?Flex Applications

Let’s look at some basic comparisons between flex products and neon in terms of the kinds of applications to consider for each. The most fundamental question is: will you see the light source, or is it behind some face/diffusion material? The classic example is an open face or closed face channel letter. For flex products, the answer needs to be that you see the tubes directly, otherwise you would simply use LED modules.

Application Neon Modules Flex

Closed-face channel letters No Yes No

Reverse halo lighting No Yes No

Open-face channel letters Yes No Yes

Exposed/bare lettering Yes No Yes

Architectural borders/accents Yes No Yes

Beer signs Yes No No

Marquee Yes Yes Yes

Sign cabinets/cloud signs Yes Yes Yes

Promotional electric beer signs-like the kind typically seen in bars-is an interesting application category because they are still quite solidly neon. Most flex products still struggle at smaller sizes, say less than 10″ letter height, due to bend radius and cut resolution limitations. The notable exception, and the reason for the asterisk, is the INCISEON product, which can be used down to a letter size of just a few inches.Closed-face channel letters, whether they are face lit, reverse halo lit, or both, remain firmly in the realm of LED modules. Open-face channel letters and exposed/bare lettering represent a great opportunity for flex products. In addition, architectural borders/accents have been the main application focus for flex products to date.

Marquee and sign cabinets/cloud signs get Yes’s across the board, mainly because there are often multiple design elements that are lit. You could consider a rigid LED product if all the tubes are straight. Most suppliers of flex products will also offer a rigid option, and some offer only rigid products, such as LED Border Tube from ILT, Skyline LED Rigid Border Tubing from Allanson, Street Wrap from Principal LED, and others.

There are more application similarities between neon and flex than there are between modules and flex, even though there are more technical similarities between modules and flex. For the most part, if it is an application that is suitable for exposed neon, then it is worth considering for flex products.

Some Players

Green LED Lighting Solutions (GLLS) is a leading LED lighting product supplier that has been innovating in the flex product space for more than 10 years. GLLS has an impressive array of high-profile clients including Disney and Microsoft, prominent installations including the Rose Bowl stadium in Pasadena, California, and events such as the Oscars on its resume.

INCISEON carries the tag line “Brighter, Smarter, Safer” in relation to neon. “INCISEON is extremely easy to work with, installation is very quick, and offering it in your shop adds instant value to your business,” says Brent Curtis, co-owner, INCISEON. “No other product gives the captivating glow that neon has always been known for, or has the design flexibility associated with neon. INCISEON products are reviving the desire for the neon look from both designers and end users, and the custom manufactured nature of the product means that it can be used in ways that neon never could.”

SloanLED of Ventura, California, was an early innovator in this space, launching their FlexiBRIGHT product all the way back in 2005. “SloanLED has sold millions of dollars of FlexiBRIGHT, with most of the applications being architectural, decorative, and accent lighting,” explains Michael Bluhm, director of Product Solutions. “Customers have been looking for a solution that reduces breakage and ongoing maintenance costs, as well as lowers power usage and the inherent risks of high voltage.”

At General Electric, Matthew McConnell is the signage application engineer for the Current by GE products including its Tetra Contour line.

“Neon has a special place in signage,” he says, “and continuing to provide sign manufacturers the ability to design and create signs that have the traditional neon look is a necessity for the sign industry. As the cost of energy goes up, the demand for lower energy consuming light sources becomes more important, and LED neon replacement products such as Contour and Contour LS fill that need.”

Flex Comparisons

In many important metrics, flex products are the best of both worlds-you get the inherent benefits of LED technology with the general “look and feel” of neon. So how do flex products compare with neon?

* Color, Brightness, and Glow-This can be a contentious topic in discussions among sign folks. How consistent are flex products to neon in terms of color, brightness, and glow? First of all, LEDs can be a single color, a range of white temperatures from warm to cool, or any of millions of RGB colors with the help of an RGB controller. But are these colors as bright and as vivid as neon? Do they have to be? This is still up for discussion and won’t be settled any time soon.

Do flex products have the iconic neon glow? The answer lies in part with the beam angle of the light. Most flex products are built as 180°, which will send most of the light forward, or 270°, which will diffuse some light back to the substrate. GLLS has several new products with a 320° angle, which will provide an even more complete glow. Current by GE’s Tetra Contour and Inciseon are both 360°, and by this metric, the most like neon. If you’re curious as to whether a flex product looks like neon, just ask your (non-sign industry) friends or family.

* Longevity-Another topic sure to have legitimate claims for both neon and flex is the longevity of the technology. As soon as you suggest that the LEDs in a flex product will last longer than neon, someone will stand up and tell you how long one of their neon signs has been running. I just had this discussion with one of my long time Neon Wizard customers. Michael Bluhm of SloanLED says it’s a toss-up, with many variables coming into play to determine longevity of a specific sign.

LED’s don’t “fail” spectacularly, but they do dim over time. When an LED dims by 20 to 30 percent, that is considered a failure. Of course, drivers can fail, and do, perhaps more frequently than the LEDs themselves. 100,000 hours, considered near the upper end of longevity for LEDs, is a very long time, especially if a sign is on for just eight or 12 hours a day.

* Design and Layout-From a design standpoint, you can lay out flex products in a similar way to neon, including to the extent of plotting out a pattern in reverse and positioning the tubes directly on the pattern. Flex tubes have clips (tube supports) and connectors (housings) that can be drawn on the pattern. Corners are drawn with a radius. Tubes are measured by footage like neon, as opposed to the number of LED modules.

However, there are a couple of important differences. As mentioned above, most flex products can only bend at a radius of a couple inches (there is no “drop bend” concept with flex), and can only be cut every couple to few inches. Blacked out tubes are also not common among flex products, primarily because the tubes are flat and don’t cross over and under each other.

* Production and Installation-The process of taking a neon pattern to a completed sign is a complex, but nevertheless well understood process. The process of taking a flex layout to a completed sign is easier … but still less understood. Suppliers of flex products are providing in-house production services, in some cases shipping a finished product ready to be installed.

Brent Curtis tells me, “INCISEON is made to order in the USA according to customer-supplied art and specs. Once it leaves their facilities it is rigid, bent to shape, and ready to install.” On the other end of the spectrum, sign shops can order 20′, 50′, or in some cases, 100′ rolls of flex product, bags of connectors and end caps, drivers, etc. and produce the final design on their own.

* Maintenance-Well understood with neon is the requirement of ongoing maintenance. Not all sign companies complain about this. Breakage is the main difference with flex products. You can throw a hundred rocks at a flex tube and you probably won’t break it. Hail won’t break it, birds won’t break it, UPS won’t break it. There is a story about driving a truck over some flex tubes and not breaking them. You get the picture.

But flex tubes are not necessarily maintenance free. The main concerns over time, as you would expect, are breaks in seals and water ingress, and electrical connection issues/driver failures. Large temperature fluctuations can exacerbate these issues as components may grow and shrink differently. However, by all accounts, maintenance is lower across the board for flex products.

* Cost-The up-front cost of flex products are higher than neon, but the annual maintenance and operating costs are lower. At how many months or years the costs balance out and tip in the favor of flex products depends on various factors, and this period seems difficult to quantify with any certainty.

It feels inevitable that the overall cost of neon signage will go up, and not just because of rising prices of the materials and equipment. What about the rising prices of the fewer and fewer neon artists who are trained and qualified to bend glass? On the other hand, prices of LEDs continue to drop. Flex products continue to mature and standardize, their manufacturing processes are improved, and product supply is increasing. This is a recipe for lower prices, and at some point the up-fronts costs will more closely align.

* Power/Voltage –Clearly one of the benefits of flex products is the use of low voltage LED drivers … the same drivers used for standard LED modules. Some flex products run on 12V and some on 24V drivers. And one important feature of most flex products is that you can connect them on both ends, doubling the footage of one continuous tube.

Helping flex products and LEDs in general is the increasing trend for municipalities to basically legislate out neon for new construction. They don’t want the liability. Time will tell if this becomes more widespread and if concessions are given for restoration of old neon signs to their old glory.

* Innovation-Certainly one important benefit of flex products is that there is a large number of LED suppliers driving new innovations in this space. Flex products are an important and growing product area for many LED suppliers, if not the entire product portfolio, as in the cases of Green LED Lighting Solutions and INCISEON. In the next section we’ll talk about where these innovations are taking us.

Flex Directions

As we look forward, there are some predictable directions for the general category of flex products…

* Standardization-Best practices in design and production will help to standardize flex products. Just as LED modules have standardized on product attributes such as optical lenses, overmolding, and LED chips, flex products will standardize on their own materials and components.

* Product Design-The race is on to design and produce flex tubes that can bend at tighter radii and cut at smaller increments. These advancements will help make it more practical to design smaller channel letters and logos. Other product attributes such as beam angle and brightness will no doubt be improved. Matthew of Current by GE adds, “We could see more diameter variations and additional color offerings in the next couple of years, or new ways of bending the product to make it easier for the sign manufacturer/installer. Ultimately our customers and their needs will guide the market.”

* Layout Tools-One of the ways that these products will become more viable for traditional sign applications is software layout tools. Aries Graphics International‘s upcoming LED Wizard 8 includes support for flex tube products and layouts, both for the design/estimation of the jobs and for the production of them through a full-scale pattern file.

* Assembly and Installation-Over time this will get easier for the sign shop. Currently the flex product manufacturers are doing most of the heavy lifting in the assembly of flex products. As shops become more familiar with the products and accessories, it will be more practical to assemble them in-house and install on location.

How to Decide?

If you have decided to give flex products a try for the first time, how do you decide among the many respected brands and products? Do your research. Like other LED products, there are different levels of service and support, different warranties, different price points, different materials, IP ratings, colors, sizes, etc. The requirements of your particular job may drive which product is the best fit.

If you haven’t looked into these products, ask for samples from your LED supplier or sign supply dealer. Turn them on, bend them, change the color if its an RGB model, put them in a channel letter or up against your brick wall. Make a prototype. Have fun.

Final Thoughts

This is not a grudge match between opposing technologies. This is not the battle of “neon vs. LEDs” of 10 years ago. It is not an either/or proposition. It is better to use the classic golf analogy of having another club in your bag-or another arrow in you quiver. If you’re knowledgeable about these products and can recognize the right opportunity, then flex products can provide a visually compelling, long-term, cost effective solution to your customer.

Are flex products ready for prime time? Yes, and they have been for a while. After all, my wife can’t tell the difference. Just last weekend I did this to her again: “Is that neon?”-this time it was-and she answered “No.” Oh well. Not everyone can have a keen eye for signage.