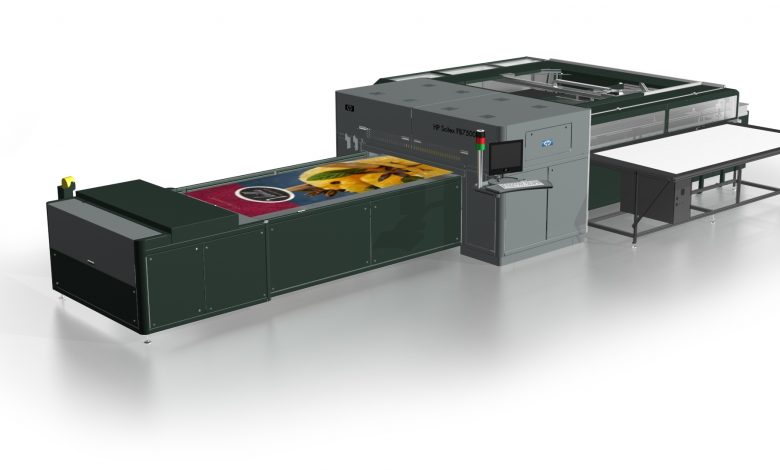

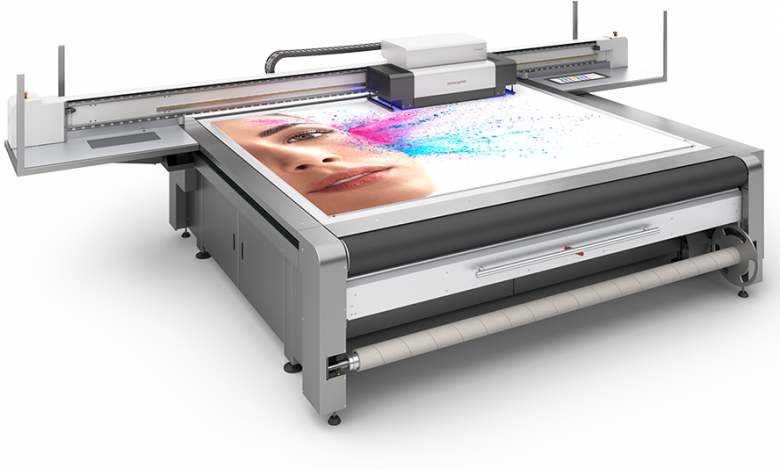

Over the last decade, flatbed digital printers have progressively improved in a number of ways-including faster speeds, better UV-curing systems, upgraded material handling, higher quality white inks, improved hybrid designs, gray scale capabilities and overall quality. All of these improvements have resulted in printers that are more flexible than ever and have given shops a plethora of new application possibilities.

Expanded Capabilities

Michael Maxwell, senior manager, Mimaki USA, Suwanee, Georgia, says that as the market continues to embrace the UV-cure printing process, more and more print service providers (PSPs) are expanding their flatbed printer competencies. “The smaller to mid-size PSPs are looking for cost effective solutions that not only provide consistent quality, but are also capable of fitting into their workspace. As a result, manufacturers are trying to scale back the footprint of their products without losing capability.”

He points out that when flatbeds first came into the market, the focus was to improve or replace labor-intensive printing processes like printing onto film and then laminating that print onto rigid substrates.

“Flatbeds allowed direct-to-substrate printing, which removed that middle step of mounting and laminating and reduces the possibility of handling mistakes. Since then, printers have been pushing the envelope on the materials being printed. They were no longer limited by matte or glossy film.”

Heavy-Duty Output Options

Maxwell says that advancements in flatbeds and their inks have enabled printing onto materials like natural wood, stone, and metals to be incorporated into the design. This has allowed digital printers to expand their portfolio of design possibilities beyond effects that could be created with roll-to-roll machines. “Designs are also expanded with the ability to build up ink. True UV flatbed ink enabled texture effects to add dimensionality to the images. To create ink or printed effects generally, multiple layers are printed of the same parts that are to create the raised texture. You can do this on flatbeds because the media position is fixed and high repeatability accuracy for ink buildup is required,” Maxwell adds.

More Enhancements in Specs

Jay Roberts, product manager, UV Printers, Roland DGA, Irvine, California, says that some of the biggest trends he is seeing related to wide-format flatbed printers are changes in size and height, speed enhancements and new developments in ink.

“Use of these inkjets are expanding into new industries, and each of these trends will play equal and important roles in the development of new and improved wide-format flatbeds. Printer manufacturers, including Roland, will seek to fill their existing market niches, and potentially carve out new niches as well. Whether the changes being made involve redesigning an inkjet’s print-bed area to “fit” a new application, or developing an ink set that enhances printing capabilities, the resulting advancements will help end users maximize success within their respective target markets.”

Non-Traditional Apps

Randy Paar, marketing manager, Display Graphics, Canon Solutions America Inc., Itasca, Illinois, adds that some of the trends he is seeing are not necessarily new but perhaps occurring more frequently now, such as increased focus on producing non-traditional applications that can demand higher margins. “These can be in areas previously underserved by UV flatbed technology such as interior decor items, industrial applications where the printer is used at one stage of the manufacturing of a final product.”

Paar notes that flexibly is helping to change the market. “Greater flexibility can equate to greater opportunity to grow revenue. Greater flexibility also means the ability to produce a greater range of applications. These can be applications that few if any others are producing compared to commoditized applications like P.O.P., banners, posters, etc. A true, stationary flatbed provides excellent flexibility to print onto an astounding range of substrates or even imprinting already manufactured items that are not simply square or rectangular. Because the printer is stationary, a jig is not always required to hold irregular-shaped pieces in place during printing.”

Flexible Tech

Dan Johansen, marketing manager, Wide Format Solutions, Commercial and Industrial Printing Business Group, Ricoh USA, Inc. West Caldwell, New Jersey, also points out that what’s great about the flatbed space is the technology keeps becoming more and more flexible. “This encourages more creative applications, which in turn encourages more flexibility. At the same time, we’re seeing flatbeds continue to increase in size and speed. The result is an explosion in capabilities and productivity in the past five years or so.”

He adds that they are also seeing everything from small shops providing short-run customized products to advanced flatbeds with expanded bed sizes designed for huge substrates and projects. “The meeting of creativity and technology is providing a way for printers to expand beyond traditional wide-format product manufacturing and into differentiating signage, P.O.P. displays and so on.”

He points out that flatbeds’ flexibility is one of the driving forces in the print market. “Enhancements to speed make customized runs of all sizes more financially viable. Expanded bed sizes allow for larger substrates, as well as larger quantities of smaller applications. Customized promotional products are a major demand by customers in this market.”

Thick as a Brick

Johansen adds that flatbeds, especially when used with custom-made jigs, are perfect for printing customized promotional products. “Bigger beds and faster speeds make larger volumes more efficient to produce. Innovative printers and print-buyers are pushing the limits of technology, and technology is growing its capabilities in response. For example, at an international specialty graphics show last year, we had a Ricoh Pro T7210 in the booth, and someone said, “I wonder if we can print onto cinderblock?” So we went to Home Depot, got a cinderblock, stuck it in the printer, and lo and behold, it worked! We printed a nice brick overlay on the cinderblock, opening up a whole new set of potential applications. It’s an exciting time in industrial print.”

Johansen says that flatbeds’ flexibility is certainly making waves, but the majority of flatbed users mostly use them for traditional sign making. “Because true flatbeds have an ability to print on varying sized materials and non-standard shapes, it is the ideal platform for traditional sign making, particularly for high volumes of double-sided printing, where flatbeds excel. Front-to-back registration-so important for a variety of applications, including lawn signs for real estate and politics-can be extremely precise on flatbeds, giving it an edge for those applications.”

Hybrid Options

Johansen adds that when it comes to UV-curing hybrids, due to their incredible flexibility, picking a single “best” application for UV-curing hybrids is difficult. “That flexibility allows you to print on basically anything that works with either flatbed or roll-to-roll, all with a space-friendly footprint compared to dedicated flatbed printers. Because hybrids excel at applications that are both typically flatbed or roll-fed, they are a great tool for meeting increasing demand for one-stop print shops. When campaigns use a mix of flatbed and roll-fed applications-sandwich boards and banners, for example-a hybrid press can help make things simple and consistent. Color matching among different applications within the same campaign or for the same brand becomes easier when you’re only calibrating for one machine with one set of inks.”

Print onto Anything

Roland’s Roberts says that its VersaUV flatbed printers, including those in the LEF series, enable users to print directly onto just about anything. LEF series models can print on materials or three-dimensional items up to 3.94 inches thick, while the much larger LEJ-640FT flatbed is capable of printing on substrates and objects up to six inches thick and weighing up to 220 pounds. “Besides being able to print eye-catching signage and P.O.P. displays on a variety of substrates, the unique capabilities and versatility of these innovative devices has opened up a world of ‘out of the box’ opportunities for product customization and personalization. Businesses of all sizes-ranging from ‘Mom and Pop’ print service providers to Fortune 500 corporations-are using Roland’s VersaUV flatbeds to customize everything from carrying cases, cell phone covers and shoes to table tops, lunch boxes and surfboards.”

He adds that in addition to printing CMYK inks on a vast array of items, Roland VersaUV flatbed printers allow users to incorporate stunning textural and dimensional effects using specially formulated gloss and white inks.

Customization

“UV-LED flatbeds are ideal for printing CMYK, gloss and white inks directly onto a vast array of substrates and objects. The unique design of flatbeds like those offered within Roland’s LEF series, makes these UV inkjets perfect for customizing everything from golf balls and pens to smart phone and laptop covers.”

Roberts explains that Roland also offers a RotaPrint attachment for it’s LEF 200 and LEF-300 printers that makes printing on bottles and other cylindrical products easier than ever. “Roland’s larger LEJ-640FT opens up an even larger world of options for companies and PSPs, allowing users to print directly on a wide range of oversized and oddly-sized objects, including doors, tables, pallets, decorative stones, lunch boxes, and much more.”

Standing Out from the Crowd

Paar says that the best applications for true, stationary flatbeds are producing applications that hybrid printers struggle with. “As a result you are eliminating a lot of competition with hybrids by taking this approach. One of the most exciting applications we’ve seen is dimensional printing where the UV inks are built up on the substrate similar to a 3D printer. This technique can produce everything from subtle textures like woodgrain, alligator skin, embossed type, logos, etc. to even the printing of braille signs accurate enough to be ADA compliant.”

He adds that the best-suited applications for hybrid UV printers, in his opinion, are the printing of square/rectangular boards.

It’s All About the Ink

Mimaki’s Maxwell believes that advancements in inks are what’s broadening the flatbed’s flexibility. “Most UV ink in flatbeds is limited to a few years of life expectancy for indoor applications and outdoor life expectancy is generally calculated in months, but that’s changing as ink technology advances. Even a few years ago, flatbeds were limited to materials that were not heat sensitive because of the common use of halide lamps for curing.”

He explains that as technology progressed and created LED-based UV curing lamps, the ink chemistry has advanced with it and was modified to be able to be cured via LED. “Mimaki was a pioneer in UV-LED ink that opened up the ability to print onto heat-sensitive materials like PVC and thin films with higher quality. Or rigid materials like Dibond that would have its core melt and warp under the old halide cure lamps.”

Maxwell says the best applications for true LED-UV flatbeds include PVC sheeting, foam core, acrylic, and composite metal. “True flatbeds have also gained favor with industrial-focused printers. The ability to do multiple objects with full customization on each piece is attractive to these types of providers, and the additional area enables more productivity,” he concludes.