Finding Your ROI in Grand Format

Understanding ROI is one of the most important factors in the purchase of a grand-format printer

Grand-format printing has been in the industry for more than 20 years. It started with the traditional screen presses, moving its way up to UV-cure technology, which currently is the most popular curing technology for grand-format printers.

Grand-format printing typically measures around 96 inches wide or bigger. According to research, grand-format printing services are driving a massive portion of the signage market and growth in the printing industry. In fact, its printing is outpacing popular digital alternatives like LED video screens in terms of growth. Consequently, no matter what your marketing needs may be-including vehicle wraps or promoting your brand with banners-grand-format printing is typically a solid option for your graphics business. Following are some of the benefits of using these grand-format printers, which help your company to attain efficiency.

Output

Grand-format output is highly visible to passersby, making it ideal for marketing campaigns, and the images are often made with durable, weather- and sun-resistant materials, making them ideal for outdoor as well as for indoor campaign use.

Grand-format printing services are mostly used to produce massive banners, and these banners are a common application. Consequently, grand-format banners dominate conventions, festivals, and expos for days, weathering the environment and projecting brand-orientated professionalism by remaining intact and vibrant. Versatility regarding shapes and sizes makes them beneficial to budgeting and creativity. Many of these banners are available in vinyl or nylon mesh, adding to their longevity and UV-resistance, and keeping them fresh, bright and ready for repeated use.

Regarding the range of mounting materials available, grand-format banners employ heavy duty supports to keep them in place, extra-large grommets and double folds are put in place so they can resist persistent and windy conditions. These banners are often used in window displays, building wraps, full coverage for walls, and custom designs, offering a versatility that adds extra value.

Competitive Advantage Over Conventional Presses

With large-format printers you can use either RGB or CMYK inks to a create rich, deeper colors that are photo-realistic. These brilliant images are perfect for photographers, artists and TV networks. Also, when it comes to cutting in printing batches of grand-format jobs, you can develop custom print and cut pieces that can be scaled up or down as required.

These printers have plenty of available waterproof substrates and coatings that help them last longer. This makes grand-format printing more durable and utilitarian than other printing systems. Typical conventional printing presses work with individual paper-based sheets or paper rolls, whereas grand-format printers use large rolls of varied materials. In addition, these printers can also print on tiles, wood, hard plastics, and other rigid surfaces.

Businesses find grand-format printing an affordable way to promote growth in terms of marketing. Cost is relatively reasonable because of the production process; thus, grand-format printed banners are a popular marketing investment that can be reused or easily replaced as needed.

Additionally, they have a proven record of catching the eyes of consumers due to their size and brilliance. When people see an official sign on the grand banner they react, they take note and they are more likely to make a consumer’s choice. Grand format printed banners increase foot traffic to a business and add a sense of legitimacy to a brand through their polished and massive presentation.

Grand-Format Printer Solutions

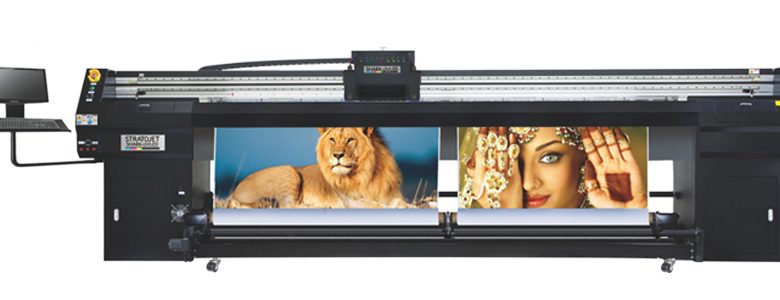

Grand format printers are available in several platforms, each geared toward different types of output. Printers are available in flatbed, roll to roll, hybrid or dedicated fabric printing platforms.

Flatbed Printers-Flatbeds are printers characterized by a flat surface upon which a material is placed to be printed on. Flatbed digital printers use UV curable inks that are then exposed to strong UV-light to cure them. Some of today’s flatbeds use an LED-based UV cure lamp that produces less heat when activating the inks. The UV-cure process allows for printing on a wide variety of rigid surfaces including sheet plastics, wood, metals, canvas, carpet, tile, and even glass.

Roll-to Roll Printers-These are characterized as printers for printing on flexible substrates like vinyl, banner material, graphic films, and etc. Inks for these printers can be aqueous (water based) for interior applications only, and UV-cure, solvent, eco-solvent or latex inks for indoor/outdoor applications.

Hybrid Printers-Hybrid printers, generally, are those that can print onto both flexible and rigid substrates. Some hybrids are basically roll-to-roll printers that have an optional table to accommodate rigid substrates. Some are basically flatbeds that have an optional roll-to-roll option. And some are purpose-built hybrids with both functions built-in, and can print equally well on either substrate type.

Fabric Printers-This is altogether a different industry of grand-format printing. Grand-format fabric printers are characterized under dye sublimation technology. These machines print either onto transfer papers that are then used to transfer the image onto fabric; or they can be built to print directly onto fabrics. Some grand-format fabric printers have built in calendaring units to fix the dye into the fabric, others require a separate calender or heat press to complete the process.

Nuts and Bolts of ROI

The acquisition of a piece of equipment like a UV-cure inkjet printer is an investment in the future of your company. You can compare it to buying a forklift or fleet of trucks for some industries and the sizeable initial price tag makes sensible investing essential. When buying a large-format UV-curing flatbed printer, it is essential that some initial steps are taken before finalizing all contracts. Things like pricing and space must be considered carefully, and considerations of a more granular nature must also be weighed.

Return on investment in grand format is one of the most important factors in the purchase of printers or presses. The ROI discussion starts with the assumption that you understand the right applications for your internal clients, printing quantities for your applications and that you are conducting an ROI analysis between printers that are a good fit for your jobs, volumes, and output quality requirements. Then, you can start looking at which specific printer will produce a better return.

The primary elements of calculating ROI are:

- printer cost

- volume of production

- value of output, and the

- cost of production

There are other elements as well for a better analysis, which impacts the profitability of each job, like expected waste of material due to printer issues, or false productivity statistics given by manufacturers.

Since we are discussing ROI, there is one thing we cannot ignore, which is pricing per square foot as these printers require a closer look before investing. This is a cost that would play a very significant role in the business. There are a lot of printers available in the market at competitive prices, though after purchasing such a printer, the unit may yield lower profits for the users than estimated-often because the cost of production ends up being higher. Production costs include the cost of inks, consumables, daily maintenance parts, etc.