Featured Project: Graphic Displays for 3A Composites HQ

ACI Design Icn. utilized brands from 3A Composites to create the graphic displays

Design firm ACI Design Inc. of Indian Trail, North Carolina, was hired to create and install an array of graphic elements to decorate 3A Composites USA‘s lobby, business offices, and product showroom shortly after the company moved its headquarters to Davidson, North Carolina.

“Executives at 3A Composites wanted to demonstrate the company’s materials in any number of capacities, including office and lobby decor as well as showroom graphics,” says Dain Richie, partner/designer, ACI Design. “They wanted to show the scope and range and creative possibilities of these materials utilizing dimensional fabrication and digitally printed graphics.”

3A Composites USA specializes in manufacturing substrates for the display and graphics, framing, and architectural markets.

As a full-service design and production studio, ACI Design was familiar with 3A Composites’ product lines, often turning to the company’s rigid substrates to create trade show exhibits, displays, corporate environments, museum exhibits, and large-format graphics for clients.

Richie explains, “We create a lot of 3D logos for trade show booths as well as custom printed panels for installation within exhibit systems. Marketing graphics are constantly being updated. Sintra is always popular and a great substrate for these design elements because it prints so well and is easy to work with.”

ACI Design utilized brands from 3A Composites and Alucobond Plus to create graphic displays for the 3A company headquarters. Graphics were digitally direct printed with an Agfa Anapurna flatbed printer and Agfa UV-curable inks.

Showroom graphics

ACI Design created a 3D graphic with rigid substrates, like Fome-Cor, Gator, Sintra, and Dibond, to cover a 23′ wide X 9′ tall wall space in 3A’s showroom. The background base layer of the large-scale graphic features a black-and-white image of clouds printed with white ink on 3mm Black Sintra and screwed to the wall.

Covering the clouds is a wedge-shaped shadow box created from 3mm Dibond in ultramarine blue gloss. “We laid this big picture frame out in CAD software and used a kerf technique to cut a groove to bend the material to this shape,” adds Richie.

An additional rectangular shadow box created from 3mm Dibond in jet black gloss featuring circular cutouts to expose LED lighting is positioned to highlight product presentations. “The lighting was used to ensure that these graphics popped off the wall,” said Richie.

ACI Design used Dibond to create custom mounting studs and supports for this large-scale display.

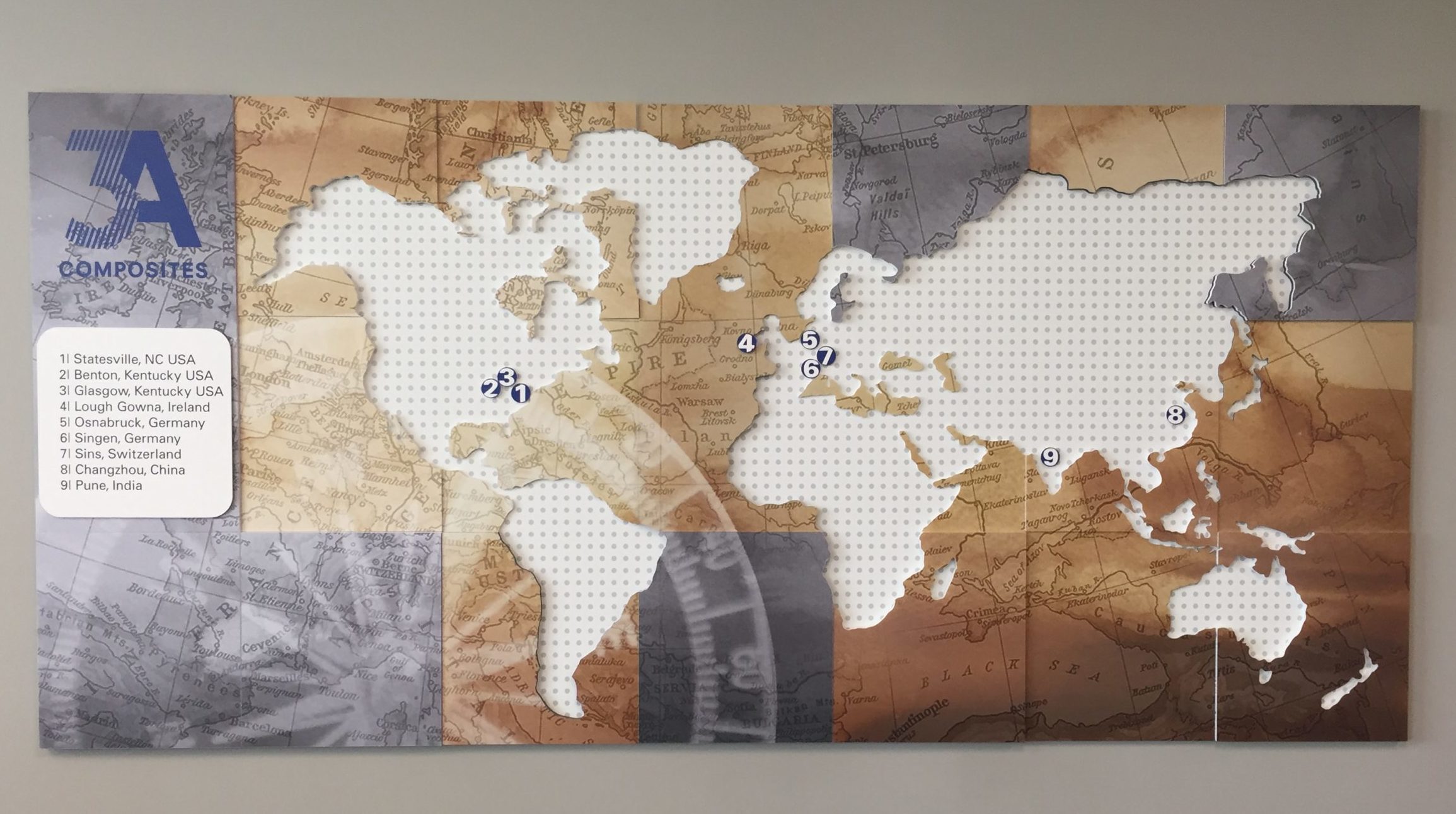

Conference room map

ACI Design utilized foam-centered board products to create a dimensionally layered map highlighting the company’s locations for display in the conference room. The 8′ X 4′ map presentation is mounted to a common base of 3mm bright white Sintra and features built-in square tiles of the company’s foam-centered boards.

Hallway display

ACI Design decorated a 42′ long hallway with images of project applications created with rigid substrates and Alucobond Plus. ACI Design created a series of interlocking open picture frames to produce “a museum-like timeline effect,” according to Richie. Photos were digitally direct printed to 3mm foam board. Product headers were fabricated from 3mm Dibond in Butlerfinish copper layered with product names routed from 3mm bright white Sintra. The hallway display features 800-plus components that were installed with magnets to allow for easy updating.

ACI Design decorated a 42′ long hallway with images of project applications created with rigid substrates and Alucobond Plus. ACI Design created a series of interlocking open picture frames to produce “a museum-like timeline effect,” according to Richie. Photos were digitally direct printed to 3mm foam board. Product headers were fabricated from 3mm Dibond in Butlerfinish copper layered with product names routed from 3mm bright white Sintra. The hallway display features 800-plus components that were installed with magnets to allow for easy updating.

Office decor

Thirty-eight project application images were printed on 3mm foam board to display in pairs in 19 business offices. ACI Design created custom frames, both vertical and horizontal, and grooved to accommodate images that can be easily updated. The custom frames were mounted to the wall with decorative aluminum standoffs.

Lobby logos

ACI Design created two LED-backlit box designs with a 3mm aluminum composite sheet to display the 3A Composites logo in the lobby entrance. Richie explains, “The inner face is white with a lid that goes over it made out of blue Dibond.”

“It was such a fun project to complete,” adds Richie. “It was a wonderful opportunity to create a custom design and deliver it from engineering through installation.”