Fabulous Fabric: How Trade Show Displays Can Impact Sign Shops

Trade shows have played a major role in the rise of fabric printing. The advantages are many, and there's no reason sign shops shouldn't get into the act.

Ask any “Average Joe” about fabrics, and he’ll probably cite an article of clothing or some sort of stitching project. It’s true, fabric has a place in several industries and is used in many different capacities. When talking about printed fabrics, one might imagine a T-shirt or another wearable. But where printed fabrics are really exploding on the scene today is in the signage market.

Fabric has always been tied to signage-as part of flags, banners, backdrops, and more- but now it is replacing other traditional substrates, especially in the trade show arena. With shipping costs and ease-of-assembly always prominent issues at events, fabrics provide effective solutions to assemblers of booth structures. Fabric is easy to handle, versatile, cost-effective and provides much creativity in design. On top of that there are many advancements being made to bring fabric to other segments in the sign industry, growing out from the trade show space.

According to Alex Frederick, marketing supervisor, Orbus Exhibit & Display Group, “Soft signage is regularly being incorporated into all sorts of interior environments via banners, hanging structures and backwalls to relay messaging to customers and enhance brand awareness.”

Trade Show Trade-Out

If you’ve ever been to an industry trade show, you’ve likely seen promotional displays in all sizes, shapes and colors; they are made from a variety of substrates, including fabrics. But why are fabric products seeing an uptick in usage? For one thing, trade shows are a perfect environment for fabric applications, and there is an extensive amount of benefits to using fabric.

“Fabric is a popular choice for trade show graphics for several reasons. The right fabric printed in the correct manner provides brilliant graphics, especially when utilized in backlit frame systems,” shares Mike Compton, print media product marketing manager, Top Value Fabrics. “Fabric graphics are also very versatile for several trade show applications including backlit and Silicone Edge Graphics (SEG) frames, roll-up banner stands, table covers and many more.”

Companies that exhibit at trade shows typically have a set budget in mind when they commit to participating. Those budget numbers can be controlled by limiting the expense of labor, shipping, maintenance and additional hardware or supplies. This is where fabric materials can give companies a way to limit spending on booth assembly.

“Drayage and rigging are two huge factors when it comes to trade shows costs,” explains Allison Pocewicz, senior customer experience liaison, Fabric Images. “Both are priced based on weight. Fabric is a lightweight option, especially when compared to traditional hard surface offerings. Fabric is commonly integrated with an aluminum framework, which is known for its lightweight properties.”

These are qualities that are noticeable and well-known in the industry.

“Fabrics are popular because they are so versatile, durable, lightweight and easy to maintain,” says Frederick, who mentions that Orbus offers product lines such as Xclaim, Hopup, Formulate and Vector Frame. “In terms of packing up and shipping an exhibit to multiple trade shows, fabric is more cost effective over shipping a heavier substrate that does not compact the same way.”

Compton reiterates that, “Utilizing fabric graphics for trade show applications saves money on shipping, installation and labor since they are lighter weight than other substrates.”

Another important consideration is the actual presentation of a brand or product at trade shows. Many companies will have a rigid rectangle backdrop promoting their wares that sometimes gets lost in the shuffle. Fabrics allow for some truly eye-catching designs that many other traditional materials cannot offer.

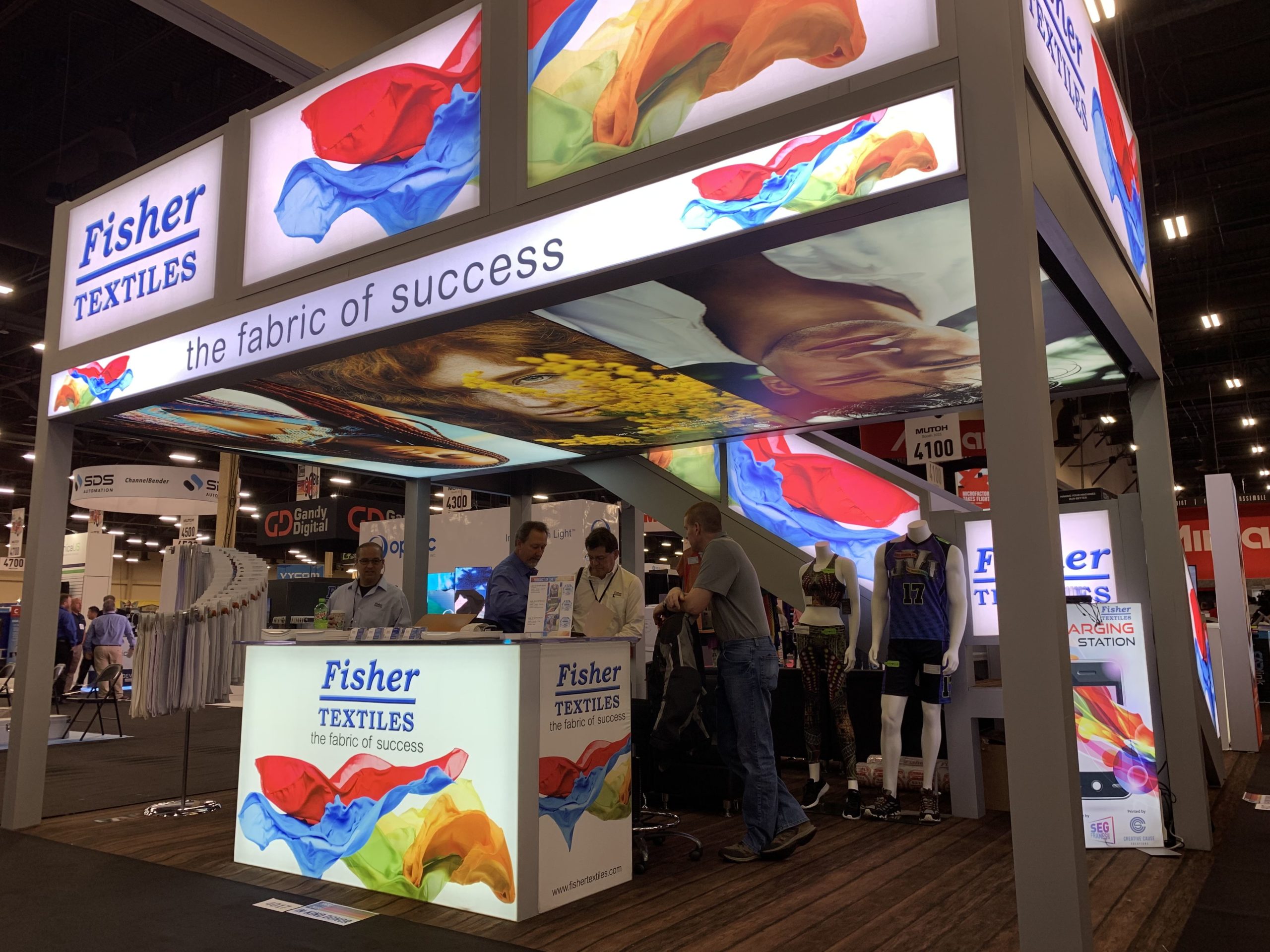

“Knit fabrics are popular because they allow for more creative geometric shapes and designs for the different dimensions of trade show booths,” says Jeff Cheatham, director of sales, Fisher Textiles.

Pocewicz expands on this benefit, adding, “Along with weight, fabric also offers flexibility. One aspect of this flexibility is with the overall design. While some designs are standard and square, many are complex and organic, something that is difficult to achieve with alternative construction methods.”

All these factors allow exhibitors to create a very attractive environment in their booths while using an easy-to-install and cost-friendly product.

Benefits Versus Alternatives

With trade show graphics, there are many different options. Traditional 10′ x 10′ booths are perfect for pop-up structures with attachable graphics. Very large booth space can accommodate towering constructions and massive hanging signage. Exhibitors have choices to make about what materials to use, whether it’s vinyl, PVC panels, fabric or something else. When opting for fabric, however, there are several benefits that are listed in detail below.

Weight and Size

For trade show exhibitors, typically more bulk means more money to spend. Packing and sending large, heavy graphics that are shuttled to and from a warehouse carries both monetary and time costs.

“Since fabrics are much lighter in weight than solid substrates, printed fabric graphics can be easily shipped and installed, saving on intensive labor and freight,” says Compton.

The other issue is size. Some substrates must be specifically paneled to fit the space allotted for the graphics.

“Graphics can be printed on fabric up to 16 feet in width,” shares Pocewicz, “which means that messaging up to that size does not require seams.”

This keeps the message consistent throughout the graphics and does not require the installer to align and “fit” the message across seams on several panels.

Ease of Use

Perhaps the biggest advantage in working with fabric is its versatility. Users can easily pack it, stretch it, hang it, and change it.

“Displays with fabric graphics provide an excellent opportunity for businesses to switch out branding or messaging as needed,” explains Frederick. “Great display solutions that allow for easy change include fabric banners, backwalls, columns, counters and hanging structures. These tube frame displays all feature pillowcase fabric graphics, which create a more sophisticated look.”

When actually transporting and storing these graphics, they can be “rolled, and in many cases folded, which offers a significantly lower cost to ship versus conventional rigid solutions due to the lower weight and smaller footprint,” Pocewicz says. “Often, aluminum frames are used to tension the fabric and these collapse down into smaller pieces as well, rarely requiring elaborate skidding/packaging. It is not unusual to use a fabric display repeatedly and most standard fabrics can be machine-washed. Typically, the cleaning is a few hundred dollars and well worth it.”

Ultimately, the impact trade show graphics have on booth visitors has much to do with the way the graphics appear and how well they are installed.

“Benefits of fabric graphics include the ability for unique branding and easy change out of graphics, drawing more attention and visitors,” says Compton, “which is the key to success for every trade show.”

Lighting

The composition of fabrics allows for effective front and backlit lighting. This can also project a brand or product name in way that is easily identifiable.

“With backlit and frontlit graphics, you can easily change the images and message you want to convey to trade show attendees without the associated costs of heavier substrates,” says Compton.

New technology, not only in LEDs but also in fabric, has helped to make the lighting with fabric displays better than ever.

“This is especially true with backlit panels,” Pocewicz says. “The extrusions and lighting on the market plays well with SEG fabrics that diffuse light beautifully with little undesirable shadowing.”

Cost

Cost is a common question in any sign project. Customers want to know the best quality product they can include at a price that fits into their budgets. All added, this is where fabrics can come out on top.

“There are large savings with the shipping and storage cost associated with foldable fabrics,” tells Cheatham. “Heavier substrates will create a much larger expense with the carriers. Fabric is relatively inexpensive versus most hard substrates.”

With every aspect that is being considered, sign makers should assess how the graphics will be used when determining which materials to use.

“The key to working with and printing fabric graphics is understanding exactly what fabric you need for each application,” explains Compton. “This is very critical when printing backlit graphics. For this reason, we highly recommend print service providers rely on their fabric vendors, not just to supply them, but to consult with them on the best fabric choice for their needs as well as how to properly print, finish, ship and install trade show graphics.”

The Print Side

The printing aspect is where sign makers can distinguish themselves from others. Once it is decided that fabrics will be used in a trade show display project, sign makers must deliver on creating the best impact of the printed graphic.

“The best way to print on fabrics is through dye sublimation,” explains Frederick. “This offers the most durability and provides a vibrant, rich and consistent color application. Orbus produces vibrant six-color output over three meters wide. The dye sublimation process offers a wide range of color variations to match skin tones, rich blacks and textures.”

Dye sublimation is a process that is frequently associated with fabrics because “this printing technique allows for machine washing and the inks withstand over time, without cracking or crocking,” shares Pocewicz.

However, that doesn’t mean there aren’t drawbacks or even other methods to print to fabric.

“There are limitations of the (dye sublimation) technology,” continues Pocewicz, “including an inability to print on natural fibers such as cotton as well as limited outdoor color longevity. Since polyester is able to imitate so many other fibers, however, there are viable fabric options for dye sub printing in a variety of markets.”

And there are also other printing solutions outside of dye sublimation that can perform well with fabrics. Many sign shops do not own dye sublimation equipment and supplies, so it is important to note other methods that work with these jobs.

“We take pride in offering fabric solutions that fit with the various printer systems and ink chemistries utilized by our customers,” Compton shares. “This includes fabrics coated for and printable with UV inks as well as our complete line of HP Latex Performance fabrics with our proprietary coating which provides the same crock or rub-fastness and excellent color, rivaling dye-sublimation printing. Clients with UV and Latex printers can simply print, cut and sew trade show graphics without needing a heat transfer calendar and transfer paper, saving on cost of operation.”

However, Compton also notes that the “predominant way” of printing to fabrics is through dye sublimation or direct disperse inks since fabrics are mainly made from polyester. He says, “These fabrics and print systems also increase speed to market and graphic turn-around time for print service providers.”

Compared to other print methods, as well as other substrates, “Fabrics offer the option for dye sublimation printing which isn’t possible for other, more rigid substrates,” says Frederick. “Dye sublimation printing provides vibrant colors and an unmatched level of detail. This is most important when working with images that show skin tone, texture, bright whites and rich black.”

Advancements in Fabrics

Just as dye sublimation printing was once a cutting-edge process on the rise, other developments have helped fabrics gain ground in the sign industry.

“Silicone Edge Graphics (SEG) frames, both indoor and outdoor, are the really hot application now,” believes Cheatham.

Pocewicz echoes this statement by saying, “The big area of growth we have seen is the emergence and popularity of SEG graphics. Years ago, fabrics were primarily finished as banners or pillowcases. While both of these are still in use today, the Silicone Edged Graphics have taken the industry by storm.”

This is an advancement that has helped with fabrics in a number of different ways. One is the ability to withstand less-than-ideal surroundings.

“At the 2019 Super Bowl in Atlanta, we teamed up with our customer Parallax Digital Studios to print stunning graphics, utilizing our Supernova backlit and Midnight Blockout SEG fabrics,” tells Compton, “which withstood demanding environmental conditions, including significant temperature changes and precipitation. In essence, trade show graphics have extended into these type of applications for marketing and promotion by sponsors as well as meeting high quality demands by entities such as the NFL.”

As technology improves, fabric applications surge-expanding from the trade show world into other areas. In truth, fabric materials can be used in many more projects than ever before.

“Solutions that were custom 10 years ago have now become commodity items as many more have entered the marketplace,” Pocewicz. “Years ago, it was more of a novelty to have a fabric overhead sign at a show and now it is standard practice. Many suppliers have catalogs that a customer can order through.”

As sign makers become more educated in the flexibility of fabric, they can relay word to clients of the several different projects where it can be used.

“Fabric graphics continue to be implemented in new and exciting applications in the sign industry,” says Compton. “At Top Value Fabrics we are seeing extreme growth in outdoor fabric applications requiring very durable textiles such as our experience with the Super Bowl. With outdoor applications increasing rapidly, we have worked with our manufacturing partners to engineer and launch high performance, durable digital textiles.”

Another advancement that has helped with fabric usage is the ability to provide coatings to fabrics to prevent scuffing or other damage.

“Different coatings and printable treatments have allowed fabrics to be used on various print technologies,” Cheatham shares. “Some of these coatings also greatly reduce the labor cost associated with its fabrication (i.e. automated cutting devices).”

Coatings are especially important when using lighting with fabric graphics.

“Backlit fabrics, in particular, don’t hide anything so marks from cracked coatings or uneven coatings can be a real challenge,” Pocewicz says. “More recently we have seen more backlits with better handling performance, especially helpful in trade show and event applications where the fabric is set up and taken down repeatedly. There is still plenty of room for advancement in the field of coatings to come up with solutions that are environmentally responsible.”

That said, fabrics are gaining ground not only in this industry but in others. When individuals think of fabrics, they may still think of apparel products or the like, but it’s technology in every sector that helps increase fabric applications everywhere.

“There is more overlap with fabrics from other industries penetrating the sign industry,” Pocewicz says. “Now that fabrics have some longevity within the industry, materials such as crepes from the interior design market and sequins from the fashion industry are making their way into custom sign and décor elements market. Integrating different personalities of fabrics helps to define brand personality in a way that does not always rely solely on messaging.”

And all of this lends to successful fabric signage projects.