As I have watched the development of businesses over the past year, I see that it is becoming more and more popular, if not necessary, for individual shops to diversify. Being a business geared to only one method of creating products is often not viable anymore; I see quite a few crossover businesses and that is what I want to write about. I will do this in somewhat general terms because even the nomenclature for “graphics business” can mean so many different things.

So, if you are a “graphics business” and wish to expand your product line, your existing business should at least be related to the direction of the expansion planned. What I am saying is that I would not recommend an auto-wrapping business to start making sandcarved gifts, for instance.

It would seem more plausible for a graphics shop that is already printing advertising materials or garments to possibly take up sandcarving personalized items and awards. But, in the end, it is your choice. The question is: what is involved?

Graphics

The easy part of adding sandcarving to your repertoire is that, as the name implies, you are already familiar with the necessary computer programs to create artwork and layouts. Most are familiar with CorelDraw, Adobe Illustrator, and Photoshop, but there are also a variety of proprietary programs on the market, some of which come from the manufacturers of equipment you may have purchased. That’s great. But it’s not quite so easy.

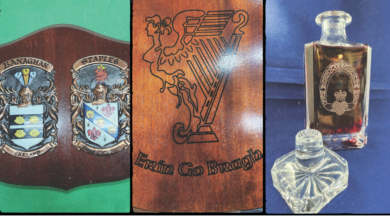

Sandcarving consists of three different techniques: surface etching, shading, and carving. Shading and carving require line art and the distinctions are made by the blasting method. Surface etching is the odd ball. It requires a block design — black areas separated from each other by a space. I am providing illustrations of the design methods, which make it easier to understand.

Once you understand those differences, you will not have any problem creating the proper artwork. For most of your sandcarving jobs on awards and small items like drinkware, you will use the block designs together with photoresist.

But I’m getting ahead of the game here. The artwork needs to be printed out on special materials depending on if you are using a laser or inkjet printer. But these are all details you will find out if you want to go this way. You will also use a variety of fonts, especially if you are creating awards. It has been our experience to limit your font offerings to about 20, or you will find your customers forever not being able to decide which one they want. Again, I am supplying a sample.

Sandcarving equipment

As with any production method, sandcarving requires equipment for two aspects of the work. First, you need to determine how you will create the stencils that are necessary to produce a blastable image on your glass. Stencils are made from a blast-resisting material in which the design to be blasted is “cut.” The stencil protects certain areas from being blasted. Here you will find again three major categories of how stencils can be produced: photoresist, laser resist, and sheet material to be cut with a plotter.

The choice of which one to use is again your decision, and at times depends on what you may already have in terms of equipment: a plotter or a laser. A less common way to create images would be to use a rotary engraver. If you go with the most popular choice, which is photoresist, you will have to invest in some equipment, such as an exposure unit, a washout unit, and a dryer. There is also one dry processing photoresist. All of what I have mentioned so far is geared towards stencil production.

Without blasting equipment, you cannot proceed in creating the desired items. What you need to get will depend on various factors. Will you produce large or small items, do you want to create a high-volume production line, and most importantly, do you have the space to place the equipment? You need to consult with the manufacturers of the blasting equipment to find the perfect solution for your intended use.

Space

Here it is very important to note that the blasting equipment needs to be away from any other machinery that uses computers for operation. Even though the equipment has radically improved over the years, there is always the possibility of abrasive dust escaping the blasting equipment, and this fine dust will get into anything! The necessary space will depend on your choice of blasting setup.

A typical blasting machine will consist of a cabinet, in which you will blast, a pressure pot containing the abrasive with which you will blast, and a dust collector, which extracts dust from the cabinet enabling you to see while you are working. There are small parts to this as well, such as gloves, lights, and hoses, but you will find out about those when you investigate the equipment.

Another consideration is whether you will use one machine or are you envisioning more than one? Your decision will affect your space requirements.

The stencil-making equipment needs to be in a space of its own, especially if you want to use photoresist, which requires a darkroom-like setup. In this space, you will work under yellow light conditions since the photoresist material is light sensitive. This would also be the space in which you will have to wash out the material.

Again, this points to how-to questions, which I would have to answer in a separate article, or you will have to inform yourself through one of the suppliers of these materials. Once the material is processed, it can go under regular light conditions for the purpose of applying the self-adhesive stencils to the glass objects you wish to blast. This will, of course, also require worktable space.

Products

Getting into the realm of sandcarved glass will open you up to a plethora of items which you could produce. Here we always suggest narrowing it down to just a few items. Once you have gained knowledge and confidence in producing these items, you can always expand your product line.

We found this to be the best approach. Awards and drinkware are still the number one products to be sandcarved. These can be glass, ceramic, or made from stone; they all can be processed in the same way, with the same materials. There is also the possibility of creating artistic pieces on flat glass or blown glass. Here is where the techniques of shading and carving really shine. These techniques can be used in a simplified form on awards and glassware.

Cost

Here it really all depends on your choices and the set up you want to have. On the low end you can count on spending at least $10,000 for all the necessary items and it can run upwards to … you decide. The question is whether you want a Chevy or Rolls-Royce. What are your requirements? Only you have the right answer.