Direct-to-film printing (DTF) has become a practical option for shops of every size. DTF allows decorators to produce high-quality, full-color prints on a wide range of garments with speed and flexibility. From long-established family operations to high-volume fulfillment centers, printers across the U.S. are using DTF to meet growing demand for smaller runs, complex designs, and on-demand orders.

The six shops featured here each take a different approach to DTF production, workflow, and customer mix, offering a real-world look at how DTF fits into production today.

Austin Screen Printing/Austin Embroidery

| Austin, Texas | austinscreenprinting.com | @austinscreenprinting |

Austin Screen Printing/Austin Embroidery offers full-service decoration and fulfillment from its Austin, Texas, facility. The 40-person shop applies outsourced DTF transfers in-house, focusing on small runs and high-color-count orders for retail and online store clients.

The shop’s DTF process starts with sales taking orders and the art team preparing designs, then placing purchase orders for the transfers. Once the transfers arrive, the team verifies them for accuracy before pressing and applying them in-house, with quality checks built in at each step. By handling applications internally, Austin Screen Printing can manage turnaround and maintain consistent results, even for small or intricate runs. “DTF is a great tool for us when the job calls for it,” said Brian Feldman, president. “Low quantities with high color counts and online store orders are really where it shines.”

Run sizes for DTF are typically 50 pieces or fewer, often under 24 units, with a standard turnaround of 10 business days. DTF is most commonly applied to T-shirts, followed by hoodies and polos. The shop offers sleeves, neck labels, and peek-a-boo pocket placements. Handling applications in-house allows Austin Screen Printing to maintain oversight of quality and timing for every job.

Creative Hands Printing

| Miami, Florida | creativehandsprinting.com | @creativehandsprinting |

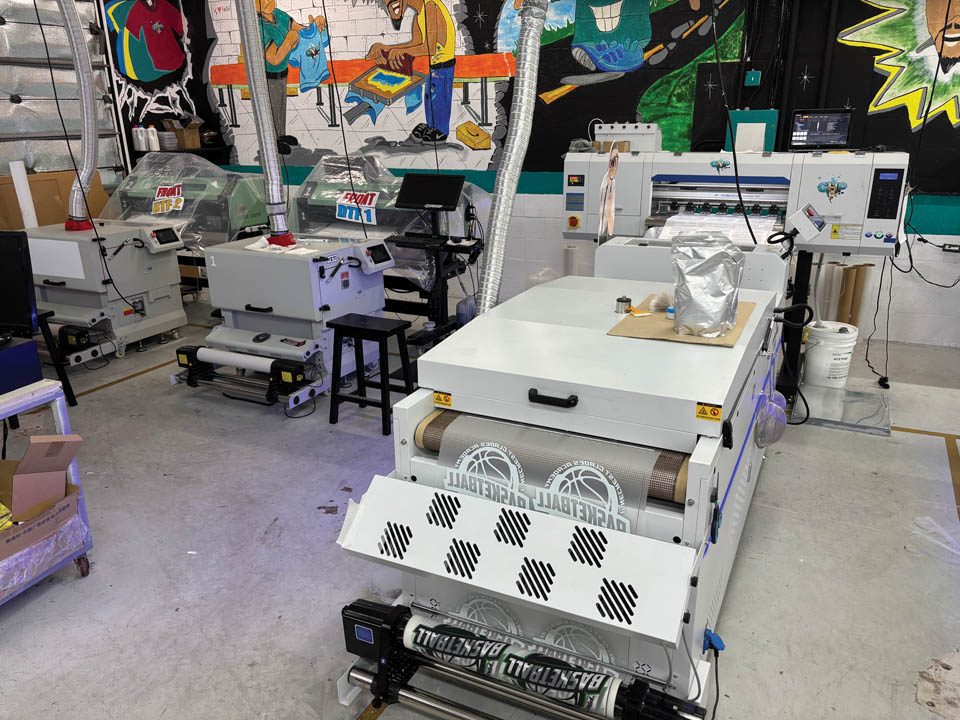

Family-owned and operated since 1992, Creative Hands Printing in Miami, Florida, specializes in DTF production while also offering signs, paper products, and stickers. The seven-person team handles all printing in-house.

The shop operates multiple Audley DTF printers, including one four-head and two two-head machines, paired with matching powder and shaker units. Heat application is handled with a STAHLS’ Hotronix Dual Air Fusion IQ Heat Press and several MEM heat presses. Creative Hands has also expanded into UV DTF with a two-head printer, and another DTF printer with extended OGVR inks is on the way. “We started with expensive Japanese printers, but we noticed it’s really the environment the printer is in that makes the difference in performance,” stated Eddie Fernandez, owner.

All DTF production runs eight passes for sharper image quality. “Other shops don’t usually do eight-pass printing because it takes longer and uses more ink,” Fernandez explained. Artwork is prepared by an overseas graphic designer who builds optimized gang sheets and uploads them to Google Drive for immediate printing. The shop serves schools, sports teams, contractors, and local businesses, with runs ranging from single pieces to more than 10,000 units. Turnaround times are typically five to seven days, with same-day service available when necessary.

By keeping all DTF production in-house, Creative Hands ensures consistent, high-quality results across every order, from single custom shirts to large runs.

Full Press Apparel Inc.

| Tallahassee, Florida | fullpressapparel.com | @fullpressapparel |

Full Press Apparel in Tallahassee, Florida, integrates DTF with screen printing, embroidery, promotional products, and POD fulfillment. The 40-person team prints small, high-color-count orders internally, outsourcing only UV DTF production.

The shop uses a DTF Station Prestige XL3 DTF printer paired with a DTF Station Miro 24 shaker. “We chose this system after hearing rave reviews from our rep and the clients he services,” said Tracey Shrine, co-owner.

DTF is typically used for orders under 48 pieces with unique print specifications or high color counts. The shop prints on almost any printable garment, including large shoulder placements, and occasionally combines screen printing with DTF for hybrid jobs. Runs are generally 25 to 50 pieces, with a standard turnaround of three to five days depending on blank availability. Shrine added, “Quality control, turn-time control, and the ability to quickly output add-on pieces or spec samples have been huge for us.” Full Press plans to add another DTF machine this year.

Shrine emphasized that in-house production allows the shop to respond quickly to client requests and deliver precise, high-quality results on every small or specialized order.

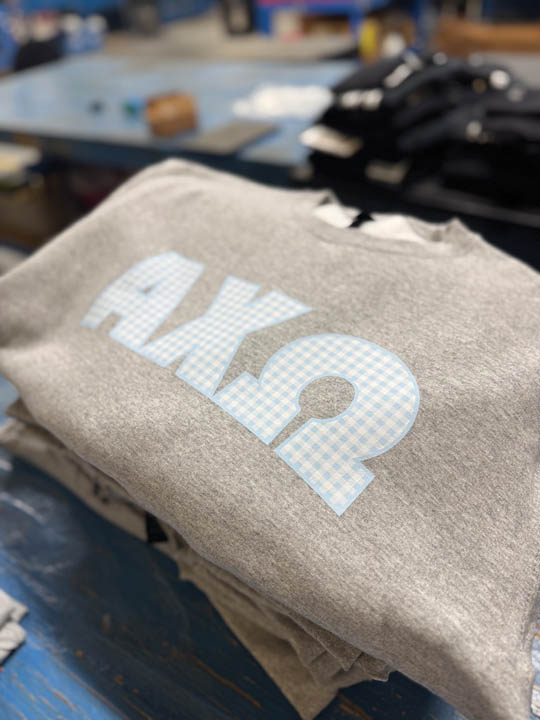

Magic Monograms

| Somerset, Kentucky | magicmonograms.net | @magicmonogramssomerset |

Founded in 1993, Magic Monograms has built its business around a variety of decoration methods, helping customers choose the process that best suits each project. The 13-person shop offers embroidery, screen printing, DTG, fulfillment, and wide-format printing, while DTF is currently outsourced and applied in-house.

With so many choices available, educating customers is central to the shop’s experience. “In our conference room, we have a table set up with examples of screen printing, DTG, and DTF, along with a short description of each technique,” explained Alan Woodson, president and owner. “It allows them to see, and more importantly, touch each technique to ensure we decorate in a manner that is in our client’s best interest.”

When it comes to DTF, Woodson has taken a deliberate approach to investment. While the shop spends approximately $1,000 per week on transfers, he is still waiting to see how DTF evolves before purchasing a machine. “Yes, it is here to stay, but as a decoration method that recently arrived on the scene, I’m still a year or two out, waiting to see if technology catches up to improve the hand feel,” he added.

From a production standpoint, outsourcing DTF transfers and heat pressing in-house integrates smoothly into Magic Monograms’ existing workflows. “It’s no different from embroidery or screen printing,” Woodson said. “The only additional step involved is that our graphic designer may design or modify the art to include more halftones so that it doesn’t come off as a bulletproof shield.”

DTF plays a key role in the shop’s online stores. “We keep a lot of DTF in stock that we use for our e-commerce platforms,” Woodson stated, noting that transfers are stored in recycled boxes above the heat press station. Orders are placed once gang sheets are ready, typically one to two times per week. “We don’t have a minimum for our customer base,” he added, explaining that pricing depends on the number of pieces and the size of the transfers.

Most DTF applications are done on T-shirts and fleece, while screen-printed transfers are typically used for fulfillment partners and neck labels. Heat application is handled using a STAHLS’ Hotronix Fusion heat press, several clamshell presses, a four-station carousel press, and multiple hat presses.

“The benefit is our ability to produce high-color jobs on short runs,” Woodson said. DTF also allows the shop to accept smaller orders with higher profit margins. Production hurdles remain familiar. “Our challenges are not much different from anyone else’s, like color profiling,” he explained, noting that supplier inconsistencies still occur, though far less often than in the past.

Looking ahead, Woodson sees DTF continuing to shape the market. “DTF isn’t going anywhere, and it has had an impact on the bottom line,” he said. He also pointed to increased competition from home-based businesses. “That isn’t going away. When one hobbyist decides it’s too much, another will pop up. Whac-A-Mole.”

QC Custom Tees & More

| Davenport, Iowa | qccustomtees.com | @qccustomtees |

QC Custom Tees & More operates in a production lane built for flexibility. Founded in 2010, the Davenport, Iowa, shop supports a wide mix of short-run and on-demand work with a team of roughly 20 employees and a service lineup that includes screen printing, embroidery, promotional products, artwork services, online stores, and on-site printing. DTF has become a key tool in that mix, especially as customer demand shifts toward fast turnaround and full-color customization.

The shop produces approximately 90% of its DTF work in-house, investing in new equipment last year to expand its capabilities. QC Custom Tees & More runs a Mimaki TxF150 DTF printer paired with a Mimaki TX-YXP8018P powder shaker, a STAHLS’ Hotronix Fusion heat press, and Mimaki RasterLink DTF RIP software. The setup supports short-run efficiency while allowing the team to handle a wide range of artwork and garment types without relying heavily on outside transfers.

QC Custom Tees & More uses DTF primarily for short-run orders, custom full-color designs, on-demand webstores, and live or on-site events where speed and versatility matter. Most jobs are priced per piece based on size and placement, such as left chest, full front, or sleeve, with no minimums required. Typical runs range from a single piece up to 24 units, though the shop has also completed larger DTF orders of up to 500 garments when the process offered the best solution.

While standard apparel makes up the bulk of production, QC Custom Tees & More has applied DTF to a wide range of items, including koozies, bandanas, hip packs, and backpacks. The team also combines DTF with traditional screen printing when a job calls for multiple decoration methods on the same garment.

For owner Michael Slyter, the value of DTF lies in its ability to expand what the shop can offer without slowing production. “The biggest benefit is the ability to offer full-color, short-run apparel, on-demand printing for webstores, and added versatility with reduced cost on transfers for on-site events,” he said. As the shop continues to refine its workflow, understanding the limits of DTF and accounting for maintenance and repair costs have become important parts of long-term planning.

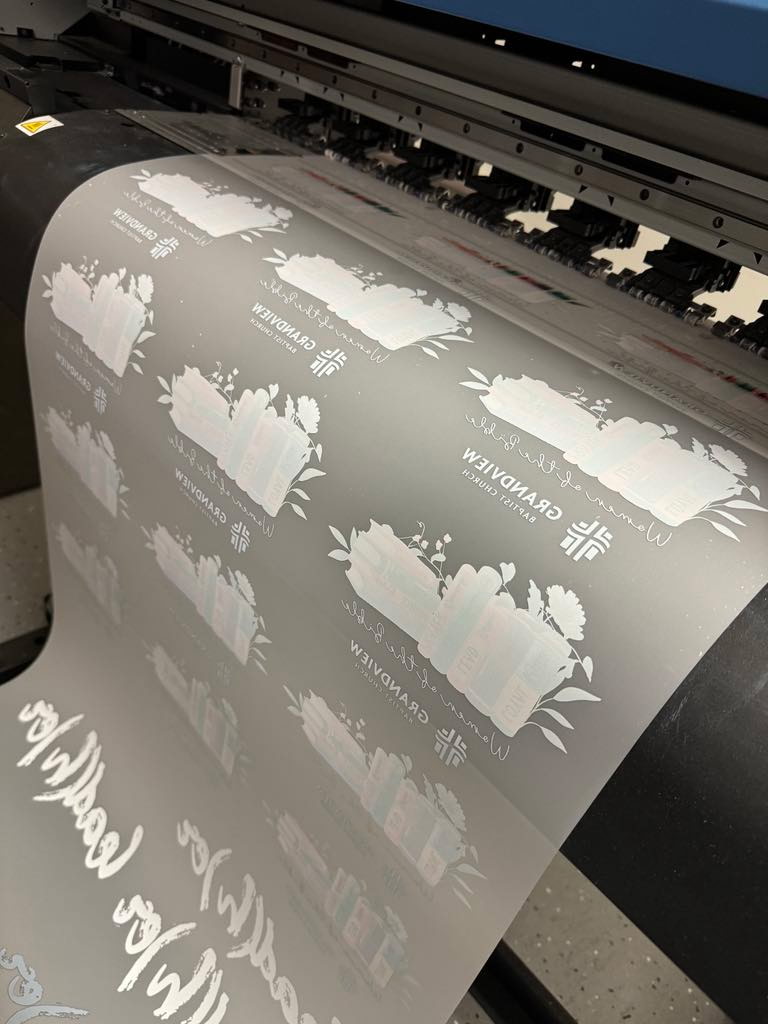

SilverScreen Decoration & Fulfillment

| Reno, Nevada | silverscreenprinting.com | @silverscreen_decoration |

With 110 full-time employees, SilverScreen Decoration & Fulfillment in Reno, Nevada, combines screen printing, embroidery, DTF, DTG, sewing, and fulfillment under one roof. All DTF production is handled in-house to support both wholesale and contract clients.

The shop runs two American Print & Supply Gladiator Four-Head DTF printing systems, with The Kraken Eight-Head DTF printer on order. Consumables are sourced from American Print & Supply and paired with CADlink RIP software. Heat application is handled by STAHLS’ Hotronix Dual heat presses, while larger jobs run on a custom-built M&R carousel. “We do between 10,000 and 20,000 linear inches a day,” said Dan Frank, CEO. That kind of volume only works if your equipment, consumables, and workflow are completely dialed in.”

Silverscreen uses DTF for garments that aren’t 100% cotton, hats and polos, and smaller runs or high-color jobs. Pricing varies by job type, with wholesale charged by linear foot and retail or contract jobs priced as a single applied-garment cost. Turnaround is often same-day for wholesale and roughly five days for application-included jobs.

Producing DTF internally lets SilverScreen maintain speed and quality for every order.