If you live in a climate where it gets cool or cold at certain times, then you already know the value of a good fleece jacket, earwarmers, or scarf. Fleece is perfect for the in-between times when it’s too warm for full-on winter gear, but too cool for a windbreaker or shirtsleeves.

This sort of outerwear is popular, and the market is only expected to grow. According to Marketwatch, the global outlook for fleece jackets and vests is expected to grow by a compound annual growth rate of 7.1% until 2030. The market was valued in 2021-2022 at roughly 48 million dollars.

Keep in mind that fleece is just a segment of the overall outerwear market, which is valued in the billions of dollars. So, clearly, this is a market segment that has a lot of potential and opportunity for growth.

Fleece outerwear is also popular with almost every demographic. Corporations use fleece outerwear as logowear. Kids wear fleeces on the playground or while playing sports. Fleece is also popular as workout gear or is worn when playing winter sports. And, as noted above, fleece is also a great choice when the temperature is hovering between cool and cold. Clearly, capturing a segment of the fleece outwear marketing could be lucrative for a garment decoration business. Here’s what you need to know to get a piece of the fleece…

Defining fleece

First things first: what exactly is fleece? Often, fleece is a synthetic, an insulating fabric made from a type of polyester called polyethylene terephthalate (PET) or another type of synthetic fiber. Not all fleece is entirely synthetic; some may be made with a cotton/polyester blend, and some may be made from recycled materials.

What really matters is that the fabric is a knit and that it’s plush. That, rather than what’s used to make it, is what allows it to be designated a fleece. If you’re dealing with sweatpants or sweatshirts, you’re most likely dealing with cotton or cotton blended fleece.

Lycra spandex fleece is essentially performance-wear fleece and has a majority of cotton with just a bit of Lycra for stretch. Microfleece is very thin and soft, and works well to wick away moisture, which makes it a popular option for performance garments as well. Polar fleece is, as the name implies, designed to keep the wearer warm and is thicker than other fleeces. All of these may just be called, generically, fleece, but knowing what type you have and from what materials it is made can help you in deciding how the garment in question can best be decorated.

If one of your marketing pillars is the use of eco-friendly fabrics or being ecologically responsible, you should know that fleece is not generally considered to be a sustainable fabric. It is often made from resources that are chemical or non-renewable.

Fleece may also be coated with chemicals to make it water resistant or windproof, which isn’t considered ideal when it comes to reducing harm to the environment. Even eco-fleece, which is made with recycled PET, is not considered an eco-friendly option. Since fleece, even eco-fleece, is often made with at least some synthetic fibers it does not biodegrade, which is another black mark in the eco-friendly column.

Fleece also tends to release lint and fibers, which can end up in the water supply, creating another ecological problem. For those who are looking to be conscious consumers and to create closets that are Earth-friendly, fleece is probably not a viable clothing option. So, if your company is dedicated to being ecologically aware, keep that in mind.

Even though fleece isn’t always considered the best option from an environmental point of view, it is a popular material for use in outwear. It’s seen in jackets, boots, hats, scarves, ear warmers, mittens and gloves, and certainly in performance wear.

Many people find fleece to be a versatile fabric that can keep them warm during a variety of activities, so it’s safe to say that fleece isn’t likely to be going anywhere. Since it seems set to be with us for the long haul, it’s logical for shops to try and secure some of this potentially lucrative market for themselves. Whether it’s a left chest logo on a corporate fleece, putting a monogram on a cozy fleece scarf, or adding an emboss to a fleece beanie, there are a lot of options for decorating fleece.

Decorating fleece

Part of the fun of fleece is deciding which decoration option you will choose. Since some fleece is made of polyester, it can lend itself well to sublimation. The caveat there is that sublimation is best suited to light-colored fabrics, and you’ll also need to test the material to see how it responds to the temperatures generally used to sublimate fabric.

Keep in mind that fleece is also not going to offer a smooth surface for sublimation, so you may have to deal with issues like crushed fibers from the weight of the press or slightly pixelated images since each fiber will be dyed to create part of the whole.

Another method for decorating fleece which creates a tone-on-tone sort of look is debossing or embossing. This might be less common than some other methods, but it does create a more high-end look. Both embossing and debossing use a combination of time, temperature, and a metal die to either create a puffed or raised look (embossing) or a design that is pressed into the fabric (debossing). Both debossed and embossed logos will not wash out over time, and the designs created using these methods can offer a unique and luxurious look for the garment.

If you would prefer to go with a more traditional method of adding a logo or image to fleece, screen printing may be your answer. Screen printing fleece is not for everyone, as it does offer some unique challenges, but if you’re up to taking those challenges on, there are some things you should know.

First, make sure you plan out your design carefully. Since fleece is often used in things like hoodies or jackets, you may have to deal with pockets, zippers, or extra seams, so you need to carefully plan where your design will go.

Make sure you test the fleece for dye migration and shrinkage before you start a print run. One way to combat shrinkage is to add a flash cure station before the first color station, or by running the entire lot you’re printing through the dryer before you print anything at all. Shrinkage can throw off registration, so it’s best to avoid it by preparing the garments ahead of time.

Another issue with fleece can be fabric movement, so make sure you tack down the garment securely so it can’t shift during printing. Make sure the distance between the screen and the fleece, the off-contact, is far enough that the ink can come through easily and not stick to the fleece. You may also want to de-lint the garment before printing, as fleece is traditionally known to produce a lot of lint and fibers, which may interfere with a smooth print.

As for which ink to use for your print, that’s mostly a matter of the type of print desired. Water-based ink and plastisol ink are most likely the types of ink from which you’ll be choosing, and both can work for fleece.

Plastisol may give you a brighter, bolder print, and water-based ink will offer a thinner print with a smoother hand. Discharge printing may also be an option if there is a need to print over zippers or seams.

Keep in mind that you may need to have a longer cure time when printing on fleece, as that may also influence your ink choice. Fleece can hold more moisture than other fabrics, so you may need to slow down the belt on your dryer and allow for a longer curing time to ensure the ink is cured properly.

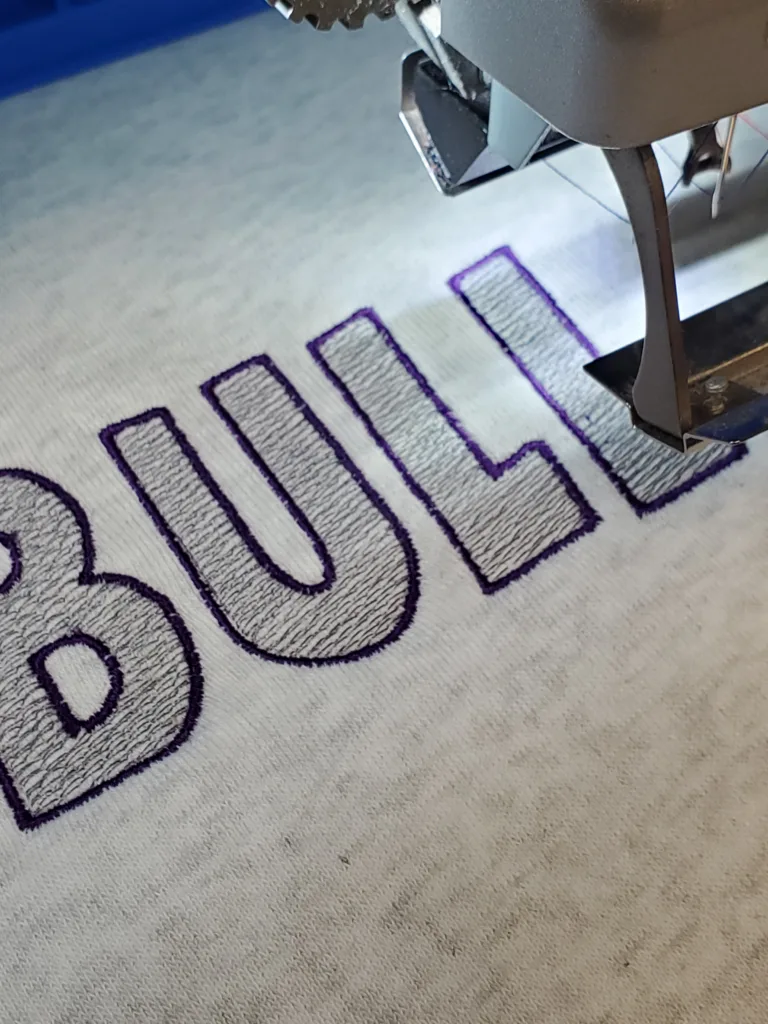

The other popular option for decorating fleece is embroidery. Here, as with screen printing, there are some accommodations that need to be made to get the best-finished design. First, since fleece is generally made of plush fibers, you’ll need to use a water-soluble topping to ensure the stitches don’t sink into the fibers.

Fleece tends to be a bit stretchy, but you can test it by stretching it prior to stitching. High-quality fleece will snap back quickly, and lower quality will contract slower, so you’ll most likely want to use a cutaway stabilizer that will resist stretching.

Denser designs may be a better option for fleece, and an underlay fill stitch can help hold down the pile in the design. When hooping, be careful not to stretch the fabric, as that will result in puckering when the design is stitched and the garment is unhooped.

Fleece outerwear can be a lucrative profit center for almost any decoration business. It is a popular garment choice for corporations, schools, ski resorts, gyms, and for fashion-conscious people who like to keep up with current fashion trends. While creating decorated fleece isn’t as easy as some other garment types, the learning curve can be well worth the profit generated.