It used to be that when we thought of fleece, the image was of sheep. Or, later, alpacas. The image, whatever was imagined, was of an animal and the hair covering their body. These days, though, the image tends to be of a jacket or a scarf, some ear warmers, or a pair of gloves. Fleece now, to most people anyway, means a garment, and is something you buy in a store, not something you shear off an animal. For decorators, this is a significant, and profitable, difference.

The fleece outwear market was valued at $24 billion in 2023 and is projected to reach $216.64 billion by 2030. This market includes everything made using fleece, including outerwear like jackets, scarves, sweatshirts, and more. As outdoor recreational activities grow more popular, and the need for suitable garments to wear for those activities grows, the market continues to expand. The advent of making fleece from recycled plastic bottles has also allowed the fleece market to grow as the industry developed innovations in technology, sustainability, and design. All of this has helped make fleece more popular, especially as those people concerned with environmental issues learn that fleece can be made in ethical and sustainable ways.

Trending fleece

Fleece has also become trendy. It used to be that fleece was made by Columbia and other outdoor brands and was mostly worn by climbers, hikers, and other outdoor enthusiasts. While fleece outerwear is still a popular garment choice for those activities, fleece has spread beyond exercise and into fashion. Actor Florence Pugh was spotted at Paris Fashion Week wearing fleece. Models Kaia Gerber and Gigi Hadid were seen wearing fleece while grocery shopping and Gwyneth Paltrow offers fleece as part of her Goop fashion line. Fleece has also shown up on fashion runways, appearing in shows by fashion houses like Dior and Fendi. While the navy-blue fleece worn hiking still exist, they have now been joined by the colorful, patterned fleece which is worn to the wine bar or while running errands or, sometimes, on the couture runway.

Tricia Blanton from About Me Monogrammed Gifts enjoys working with fleece, “whether polar fleece or sweatshirt fleece, because it’s so versatile.” Versatility is the name of the game when it comes to fleece these days. Color blocking has become a popular fleece trend. Fleece is also popping up in vibrant colors and with eye-catching patterns. Some stylists are having fun with fleece, pairing it in oversized layers or keeping it minimalist with one basic color and some eye-catching decoration.

Sustainability and eco-friendliness have also made fleece more popular among the eco-conscious crowd. Brands that can be transparent and traceable in their fleece production processes are finding customers who want fleece that is both comfy and good for the environment.

Decoration methods

Embroidery

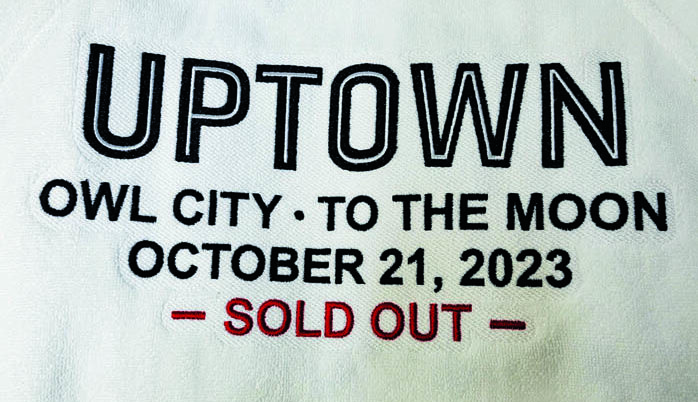

Since fleece is clearly so popular, and it looks like the popularity trend curve will only continue to rise, it appears that offering fleece as part of a shop’s product line would be a good idea. The next question, once fleece has been added, is what sort of decoration to offer. For Carlissa Book, of By the Book Monogramming, the answer is embroidery. “I’ve embroidered on fleece and I love it,” she said. “It’s always stitched so well, it’s very easy to work with.”

Liz Hennings, of Fast Track Products Inc. agreed saying, “I love the way fleece embroiders and the way it looks when done.”

For all that machine embroidery and fleece are suited to each other, there are some challenges that come with marrying design and thread to fleece. For Blanton, there is one main difficulty. “The only difficulty I’ve found,” she shared, “is with small lettering or very detailed designs that tend to sink into the fleece no matter what.” Hennings says the main challenge is “dealing with the nap and pull.”

Since fleece has a pile, stitches do sink and can become lost among the fibers. For Hennings, the solution has been knockdown stitches. As she said, “Getting the knockdown figured out for each type of fleece is critical also for a good finished product.”

Another option, the one advocated by both Book and Blanton, is water-soluble topping. Both recommend using water-soluble topping to help avoid the stitches sinking into the pile of the fleece.

When it comes to fleece, what is purchased is generally something that is soft and will keep the wearer warm. If embroidery is added, it is often small and usually adds personalization. At By the Book Monogramming, the personalization is usually “logos and initials on fleece jackets for the winter.” About Me Monogrammed Gifts sells a lot of sweatshirts and blankets. For Fast Track Products, the best-sellers are “zip front hooded jackets — the lighter weight ones.”

Direct-to-film heat transfers

If machine embroidery is not something a shop offers, another good decoration option when it comes to fleece is heat transfers. These can be large enough to cover the back of the fleece, or small, featuring things like a left chest logo.

One of the challenges with using a heat transfer on polyester fleece can be the amount of heat required. As STAHLS’ Transfer Express reminds their customers, “Choose a low-temperature heat transfer when applying to a sensitive fabric.” And “Choose metal zipper vests as opposed to plastic zippers.” The goal is to avoid melting any part of the fleece while applying the transfer.

Debossing

Finally, if your customers like a tone-on-tone look, debossing can be an ideal decoration technique for your fleece products. For those who are not familiar, debossing uses a metal engraved die and a combo of temperature and time to create a design in the fleece that won’t fade or wash away. The design is pressed into the fabric, creating an impression.

Unlike embossing, which requires puff foam and results in a design that is raised above the fibers around it, debossing stamps a design into the fleece, compressing the fibers that make up the design. It can be a very high-end look and requires less work than embossing as there is no foam required.