Custom-designed patches started taking hold in 2022, and in the last two years, retail outlets like The Baby’s Booty saw an even bigger jump.

“It’s more the novelty patches. There’s always a need for business patches, and there’s still a need for company representation,” said Eve Lowry, owner of The Baby’s Booty, an influencer and supplier based in Charlotte, North Carolina.

Lowry teaches embroidery, vinyl, and rhinestone craft classes, and owns two online stores selling wholesale and retail rhinestones and rhinestone and embroidery designs. “[But] I’m talking about the trendier novelty patches that started in the last six months. People enjoy customization and showing their styles.”

Customers are opting for things they like and that matter and appeal to them, such as representational designs of their ethnicities and affiliations to clubs or fan groups.

They’re meeting this desire with custom patches and garment labels since they are more accessible and affordable and not limited to what’s available on the market.

Labels and patches

Garment labels, often used to represent a brand or company, are made in several ways, such as sublimation, direct-to-film (DTF), and stitching, and, if woven, on specialized weaving machines. Lowry makes hers by sublimating on satin ribbons.

“DTF is like a heat-applied sticker,” Lowry said. “Sublimation is permanent. I prefer sublimation because it’s a more permanent process.”

Sublimation is best done on white or light-colored labels, while DTF is preferable for colored materials — sublimation can’t be done on darks, plus the heat needs to be able to transfer onto the polyester material. The designs should be small and simple to avoid taking away from the larger garment design.

For patches, they can be any size from an inch to large enough to cover the backside of a jacket. They can be shaped to the design instead of just a traditional rectangle and often are in bold colors. They’re found on sleeves, the back and fronts of garments, pant legs, hats, and tote bags, and they appear in places where embroidery machines can’t reach.

Lowry promotes custom patches embellished with rhinestones complementing the patch design. She offered her first “Rhinestoning for Beginners” class in January to teach crafters how to stitch a diamond-shaped patch and add rhinestones on top. She also teaches classes on how to make custom patches, giving advice on materials and methods and the best tips and tricks to use.

“You can make a patch out of inexpensive material like felt or duck cloth,” said Lowry, who started making custom patches in 2016 after doing embroidery-for-hire, including on patches.

Leather and other trends

Another trend for custom patches is using leather for the base material and imprinting one color onto it for a burnt-in look. A laser cutter cuts out the shape, and the design is done with a laser imprint. This is ideal for hats, but it also works for fleece, hoodies, and backpacks.

“It’s like die-cut leather, so it can be any shape or size as long as fits above the bill on a hat,” said Dean Cowart, owner of Palmetto Blended in Charleston, South Carolina, a custom merch shop that offers embroidery and screen printing on T-shirts, apparel, and promotional items.

Palmetto Blended offers embroidered patches, using Stahls’ Hotronix Heat Press, a press that heats from the top and bottom using a new technology that came out about one or two years ago, according to Cowart.

“For us, it was a game changer to get the heat press,” Cowart said. “It saves the step of stitching. It’s going to heat the glue from the bottom and top, so it adheres to the material.”

Other techniques for patch application include DTF full-color transfers, screen printing, and sublimation, which involve taking a blank patch and using a heat press to adhere the sublimated ink to the hat or other item.

The patches can be flex or 3D embroidered with a printed bevel and emboss look stitched onto the material; print stitch or sublimated with embroidery added to a full-color photographic image; and woven line with a flat surface and seamless finish.

“The first thing is to know the material — the limitations — and what looks good to translate into an embroidery patch,” Cowart said, giving an example. “Keep designs to two to three colors and keep size in mind.”

Sustainable as an option

Atlantis Headwear, headquartered in Venice, Italy, with a branch office in New York City, started a full sustainable line of headwear in 2018 that includes sustainable patches or decorations. The company creates recycled woven patches, recycled felt or velvet patches, and plant fiber leather patches, plus continues to use conventional fibers like polyurethane, leather, polyester, and cotton.

“Plastics are still classic and will keep going,” said Silvia Pallaro, country manager of North America for Atlantis Headwear. “We’re finding some decorations are nice to see and eye-catching but also sustainable. … The same outcomes with standard materials can also be made with sustainable materials at a slightly higher price with a better effect on life and the planet.”

Atlantis Headwear’s customers are following the trends by opting for subtle, neutral, and classic colors like earth tones, black, white, and gray.

“It’s less flashy and noisy and much more subtle,” Pallaro said. “It is transition I’ve been seeing in the last couple of years, probably after the pandemic when there was a transition toward neutral colors.”

Subtle patterns also are preferred, such as textured fabrics with an embossed pattern on the fabric and the application of tone-on-tone colors.

“Fabric is less flashy, except for some popup colors here and there, like burgundy or maroon. Red is going a lot right now, especially for headwear,” Pallaro said.

Rubber, twill are popular

Kati Sportcap & Bag in Houston plans to add PVC rubber patches to its line of offerings in the coming months due to high request.

“Rubber patches are getting really popular,” said Ben Spier, business development associate for Kati Sportcap & Bag, a family-owned and -operated cap and bag supplier with a sizable decorative business. “They’re very pronounced on the hat, and keep a fresh, new look. … It’s eye-catching; it’s newish; it’s different.”

Rubber patches generally are easy to clean and do not retain dirt unlike softer fabrics, which can lose their allure and shine if they get dirty, Spier said.

“Because it’s a rubber material, it looks nicer,” Spier explained.

Another material that’s popular for patches is twill, a high-quality fabric with a premium feel that makes the patch stiffer, lay nicer, and last longer, Lowry said. Sewing the patch onto the garment or tacking it on after adhering it with glue, using a heated adhesive, also will help it last.

“I’ve seen lots of patches fail over the years with just glue,” Lowry said. “Tacking or stitching it on will last for years. A lot of times I’ve seen the patch outlast the garment if it’s stitched on.”

Making a patch

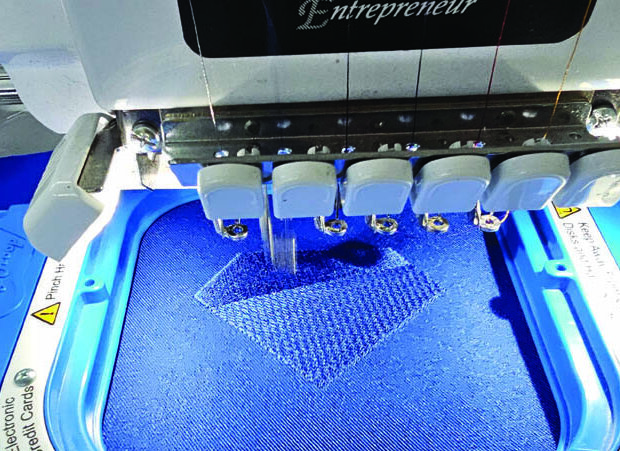

To make a patch, options include using twill or a thick clear stabilizer, such as Badgemaster made out of 4mm clear plastic. The patch shape is stitched onto the stabilizer with the twill patch fabric on top. The embroidery machine will embroider the design right onto the twill patch fabric, then finish the patch with a 1/8” border stitched around the patch.

The border improves the longevity of the patch and makes it look more professional. Because the patch is stitched onto the thick plastic stabilizer, the patch can be removed from the machine and popped out of the stabilizer making a nice and clean tear.

“Everything is done on the embroidery machine,” Lowry said. “The only thing you do is cut out the shape of the patch from the twill in the beginning, so you can lay the patch on it, then stitch the rest over the top of the patch.”

If twill is used, Lowry recommends making sure the color is the same as the patch, so that the two match, and with the plastic, avoiding cheaper materials, since they can warp the patch. Also refrain from putting too many stitches onto the patch, especially if plastic is used, to also keep it from warping.

Selecting the equipment

A few pieces of equipment are needed for making patches, such as an embroidery machine, even as small as 4” X 4”, which can make patches up to 4” in size, plus a sewing machine, or at the most basic, needle and thread. For glue-on, double-sided adhesive also is needed.

Additional supplies include a stabilizer or twill, embroidery software, and the embroidery design that’s purchased or made in-house. The design then can be put on a flash drive or transferred remotely to the embroidery machine.

SewWhat-Pro is a beginner-friendly software program that edits and transfers embroidery designs — also useful is digitizing software like Wilcom.

“Be sure to charge customers a designing fee and limit the amount of changes, because it can be difficult—you don’t want to lose money recreating designs and end up not getting the job,” Lowry said. “If it makes customers feel better, take the design fee off the final cost … as long as they complete the order.”

Working on the design

The other processes for custom patches include knowing how to properly design and digitize a patch, or hiring a professional digitizer to create the design and do the embroidery work.

“Patches are fun,” Lowry said. “They are novelty. Treat it as such and have fun with it while the trend is popular.”

Cowart recommends starting with a small number of embroidery colors, bringing in more as needed, since taking them away is harder.

“The complicated design with lots of colors does not translate to embroidery,” Cowart said.

Colors that are being used are trending to bright and more vibrant, Cowart said.

Another of Cowart’s recommendations is to use thick lines and borders and to consider the size allowance for the patch placement, such as on a hat, which generally has space for a patch 2 ¾” X 4”.

For each patch, Cowart takes the concept or artwork and translates it into the best material and patch type, providing a mockup or representation of the work to be done before production. He asks that orders be in a quantity of 25 and up, but can be smaller for patches that are screen printed or made through full-color transfers, since they can be done in-house. The orders can be turned around in 10 to 12 business days but quicker for screen printing and full-color transfers, which can be filled in five to seven days.

“Keep brand identity in mind when designing a hat, bag, or shirt,” Cowart said. “Have the same representation and consistency across the board.”

Logos carry their own limitations and peculiarities, Pallaro said. Small details are best replicated with woven or sublimated patches, and embossed or embroidered patches should be avoided, since the details won’t be able to be replicated, she said.

“Each decorative material has its own limitations, peculiarities, and features,” Pallaro said. “We consider ourselves the guide — the teacher for the client — and point out limitations and margins of flexibility in the material.”

Spier said communication is essential to avoid costly mistakes and wasting the customer’s and company’s time.

“You can never have too much communication,” Spier said. “Generally, you’re doing orders in bulk, making sure the sample is correct and the customer signs off on the sample. … You want to make sure you’re executing on what they want and not costing yourself time and money.”