Crystal awards and gifts are a timeless choice for customers who want to express their appreciation for things like years of service, retirements, partnerships, achievements, commemorations, and more.

Every order for a crystal award or gift is special, and with each one, customization is key — but the array of options and combinations can sometimes feel overwhelming. This guide can help make it simple, easy, and fast to source what your customers need while exceeding their expectations.

Your supplier’s reps can confirm which imprints work best for the designs and the personalization desired. They can also provide guidance and recommendations on how and when two or more processes can be combined to maximize an award or gift’s visual impact — and the recipient’s emotional response.

Working with your supplier opens the doors to talking about incredible ideas, but knowing the lingo is a great place to kick off the conversation. Let’s break down (pun not intended!) four popular crystal imprint options and how they differ: deep etch, color fill, subsurface laser engraving, and Illumachrome.

Deep etch

You know it by its frosty-white appearance that stands out in contrast to the clear optical crystal. This deep etch, whether of text or a graphic, is created when the smooth surface is blasted away to create a recessed, textured area. Deep etch is a timeless, elegant, and subtle way to make a statement with a crystal award or gift.

This deep etch imprint is created meticulously by hand, one piece at a time. Each award begins with the application of a mask that outlines the artwork and protects the rest of the smooth surface. Then, highly trained artisans carefully apply pressurized air and sand to carve the design. This process of etching requires a great deal of precision to achieve the desired depth and detail while making sure the design is perfectly legible, both on its own as well as in preparation for any added enhancements such as color fill.

Even with the painstaking nature of creating a deep etch, many awards featuring this imprint can be offered under quick shipping timeframes.

Color fill

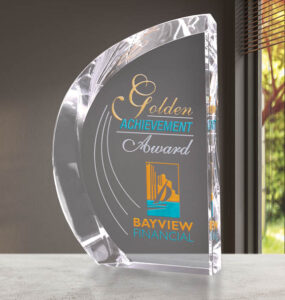

As eyes are naturally drawn to color, this is one of the most popular ways to enhance a crystal award or gift. While techniques vary by supplier (and some use proprietary methods), the process is precise, and the end product pops.

All color-fill applications require a deep etch with crisp recesses that can hold enough pigment to create the desired effect — whether it’s opaque color for a bold appearance or translucent tones allowing light to pass through.

Color fill works best with larger, non-script fonts without superfine details and lines. This is because a minimum width (indicated by the supplier) is needed for the color to take hold without spilling into unintended areas. More than one color can be used within a design as long as there’s enough space between the recesses being filled to prevent any unintended mixing of hues.

One final thing to keep in mind is that the process of color fill excludes awards with this treatment from being available for quick shipping, though the process can be performed within most standard production timelines

Subsurface laser engraving

How did that get in there? It’s the top question people ask when they see an award or gift featuring subsurface laser engraving. The next thing they do is hold the award and turn it around — and around — and around.

The answer? Science! And technology.

Getting an image inside of crystal is impressively cool. A high-tech laser fractures the crystal, one dot at a time, to produce a clear 3D image. No image is too big, too small, or too complex for this kind of state-of-the-art tech.

There are three types of subsurface laser engraving:

- 2D: Where the front features a detailed replica of an image, with a flat side view.

- Relief: Where the image appears 3D from the front but is hollow in the back.

- 3D: Where the image is fully dimensional from all sides and is an exact recreation of the art provided.

Suppliers may have stock 3D images available for reproduction, but custom designs can also usually be created using 3D modeling for an additional cost. Subsurface laser engraving typically works within standard production times, depending on the item quantity and image detail.

Illumachrome

Perhaps the ultimate in color treatment, llumachrome is the process where any four-color digital image — photo, logo, artwork, or other graphic — is applied directly onto the optical crystal.

Customers can choose for the image to be translucent or opaque, and they may even opt to double the imprint space by incorporating two Illumachrome images: one facing forward and one facing backward.

Additionally, Illumachrome art can be flooded onto the entire back side of the award, or it can be placed in a smaller area to serve as an accent. This imprint provides unmatched flexibility as it can accommodate a range of award sizes and shapes, but it is limited to flat crystal surfaces.

Whether complemented with additional imprints like deep etch or showcased alone, an award with Illumachrome presents a magnified appearance and elevated presence.

End with a good base

The saying may go, “Start with a good foundation,” but we like to think of bases as the finishing touch. A beautiful base instantly enhances crystal awards by providing an impressive stage for displaying it — and there’s something especially magical about lighted bases. These immediately illuminate a design’s details and take it from being a showpiece to a showstopper!