Colorful Considerations for Sublimation Output

How to tackle the challenge of color management

Regardless of which ink set you use, one of the challenges of desktop digital decoration is color management. With screen printing and embroidery, it’s easy to visually see the real color of the inks and threads. But with desktop digital printing, you are actually creating the colors via your software, then the printer mixes various base colors together to deliver the final image.

The first problem is that the colors coming out of the printer don’t always match what’s on the computer screen. There are two basic reasons for this: color gamut and color conversion.

Color gamut refers to the range of the color spectrum that a device can reproduce. In the case of a computer monitor, the range of color is typically larger than that of an inkjet printer. Thus, it’s possible to have colors on the screen that cannot be exactly reproduced by a printer.

The second aspect is that monitors typically use an additive process (RGB) to create color, whereas a digital printer uses a subtractive process (CMYK) to create color. Thus, you are encountering a translation issue when it comes to the exact recipe of reproducing color from screen to printer.

The key to solving this common challenge is to work with specific color profiles that have been designed to create the best match between a range of specific input and output colors. Most manufacturers of digital transfer systems offer pre-defined color palettes and/or software modules to deal with this.

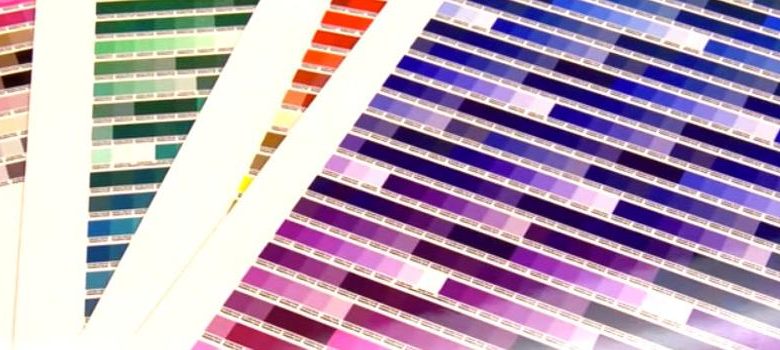

Color management can get even more challenging when trying to match a digital color to a screen-print color, and this is especially problematic in terms of producing spec samples. Perhaps the best way to tackle this issue is to print out a specific color chart, then apply it to the desired product using the transfer process. This will show the full range of specific digital colors as the look on a finished product and can be used as a visual reference for matching up to the screen-printing inks. Then, start creating a cross-reference chart to assist with matching digital samples to screen-printing production.

Most color profile systems allow for the creation of spot colors that can be saved. In the long run, you should able to create a decent database of defined colors. However, it should be noted that because of the physical difference in the inks (and the process), it may not be possible to get an exact match.