My previous articles have dealt with starting up and developing your laser engraving business — customer base, potential market segments, and so on. This month, I’d like to take a side step and talk about opportunities to develop more business by looking at different processes.

As you’ve progressed with your business experience behind you, you have gained a lot of familiarity with your graphics program. By using your graphic skills, you can create images suitable for use in different products using different processes such as direct-to-garment (DTG) printing, embroidery, and weaving. Each process involves different tricks to maximize the results you’re seeking.

If you know of businesses already involved in any of these processes, you can save yourself a lot of time and money by figuring out how best to work with them.

DTG printing

One option is to talk with a local DTG business and ask if they’re prepared to work with you and simply charge a fee for the graphic. The printer will deal with the sale and that company will sell the item directly to the customer.

If you’re interested in taking on the job yourself, investigate the cost of DTG printers. These are relatively inexpensive, but as always, you get what you pay for. It is a technology that is developing quickly so it’s best to look around and decide just how deeply involved you want to get.

One point with printers: I saved money by getting a less expensive machine, knowing at the time I couldn’t print on black or very dark-colored garments. (To get the best results, a white “base coat” has to be applied.) I decided not to go that route, and in retrospect, I probably should have.

Pretreatment and/or post-treatment may be advisable to get and preserve the best quality image. This in and of itself is not that complicated, and further machine purchases, such as heat presses, may not be needed. So, decide how far you want to get and proceed accordingly. Remember that this is not the same as screen printing, and the colors may not be as vibrant as a screen-printed product.

Embroidery

Speaking to commercial embroiderers, I realized that there would be a lot of expense involved, and there is a fairly steep learning curve. A lot of inventory can be wasted during that process, the cost of which needs to be taken into account along with the embroidery machine itself, of course! These come in varying complexity for differing thread choices, and, of course, the associated expense that goes with those options.

I know a commercial embroiderer, and we have a deal that works for both of us. I supply the graphic, he charges me a set cost based on the garment, and I sell to the customer.

Woven products

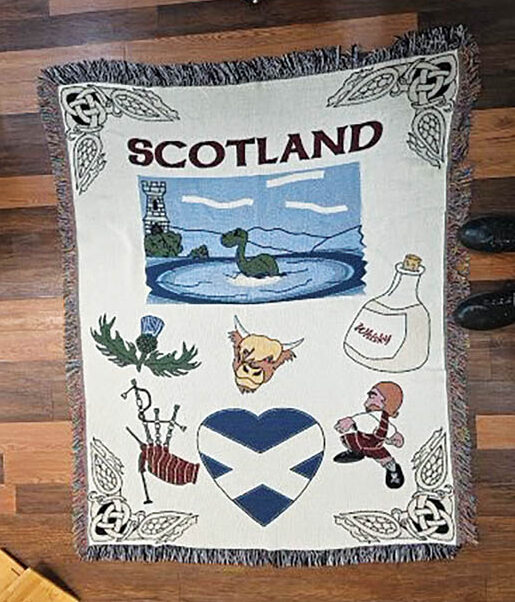

This is something you are, I would say, never going to take on yourself, and is probably the simplest process to adopt for your business. There are several companies in the U.S. who will accept your graphics and weave the products, ranging from cushions to apparel, wall hangings, and throw rugs. Two things: The weaver can’t always match your colors exactly, so there can be a bit of a learning curve as you figure out the best options from your palettes that will work for the weaver’s thread color matching. Second, the weaver will have strict guidelines as far as the type of graphic they can accept and the maximum template size for each category.

Pros & cons

There are several advantages to offering these services. All three options give you an enhanced product offering, and obtaining samples of each for display adds a lot of color to your store displays. You have added potential for profits, particularly with designs for a general customer base as opposed to “special” jobs for individual customers. (For which you can charge a little extra. For example, there is a $30 difference between my “general” items and “specific” items.)

Even with the general items, if you create your own graphic, you are still producing something that is unique to your business, which itself can be attractive to customers. There can obviously be a potential for you to develop a “wholesale” business for other businesses that might want to carry your products.

The disadvantages are that you will be faced with choosing some capital investment as opposed to working completely on a wholesale basis with suppliers. As I mentioned, I opted to purchase a DTG printer, but my woven and embroidered items are completed for me by other businesses. In my case, I negotiated a cost that worked for my embroidery supplier and allowed me to have a worthwhile margin for my retail prices. Similarly, the wholesale cost I was quoted from my weaver left room for a reasonable markup.

The single biggest disadvantage with DTG work is the number of products you want to carry and, subsequently, the amount of inventory you’ll need when offering different sizes and colors. This is manageable, however, and doesn’t need to cost as much as you might think.

This kind of work may not fit in your business model, or you may be happy with the volume of your engraving business. I can say that adding these processes to our business has been a definite plus, and I would encourage you to at least consider them if you want to add a couple of strings to your bows. As always, good luck!