The wide-format printing industry was already moving toward more automation, but the pandemic’s restrictions moved up the timeline. Print shops of all sizes have struggled to find and keep workers because of COVID, and the pandemic has changed the way many industries do business, with much of it moving from brick-and-mortar storefronts to robust e-commerce sites. To do that, the technology had to advance more rapidly than expected.

Automation was “something we were moving toward way prior to COVID and the pandemic but, like so many various areas of the market, it really sped things up quite a bit,” says Becky McConnell, Fujifilm North America Corp.

From add-ons to existing printing presses to more robust printing and workflow software, the largest manufacturers have had to adapt quickly. Much of this technology was already available in the marketplace, but only the highest production shops were taking advantage of it. Now, printing equipment manufacturers are seeing a trickledown effect to smaller-volume shops.

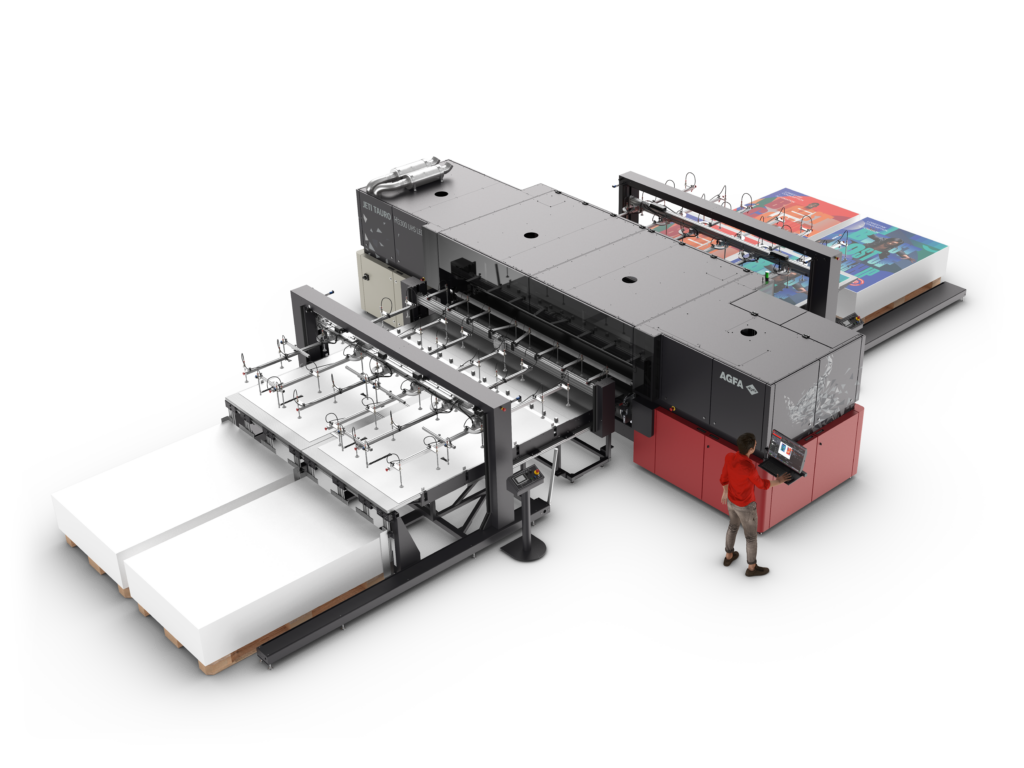

“There is a drive toward automation,” says Deborah Hutcheson, Agfa Corp. European countries were quick to adopt automation because they were looking to minimize their dependency on people. Now that the U.S. is experiencing labor shortages, it is “driving a lot of people to reconsider automation on their equipment. Also, as brands accelerate their time to market and look at shorter runs, she says that also is driving the need for automation.

Wide-format printers

As printing presses get faster the need for automation increases because operators have difficulty keeping up.

“If you have high-volume production and you want them to keep up at that rate, nobody can feed at the rated speed for eight or 16 hours a day. It is not practical,” Hutcheson says. That means shops must move to full automation or partial automation. “The goal of automation is to provide customers options to help them improve productivity but, most importantly, efficiency,” she explains. “In today’s world, everyone is looking at ways to reduce the total cost of print manufacturing, adding more capital investment upfront with an understanding that there will be an ROI bump in the end.”

Efficiencies are more important for higher volume shops, and Agfa offers lower-cost machines that also have automation capabilities. Customers of Agfa can purchase machines in manual mode and then add on automatic board feeders or stackers. For roll-to-roll machines, clients can put two 63-inch master rolls on the machine and let it run unattended.

“What that means to customers is they can have one operator manning multiple machines. They are just setting the machine up and letting it run,” Hutcheson adds.

Agfa’s approach is to give customers the ability to kit out their press to best meet their needs. If down the road they decide their business has grown enough to merit additional automation, they can always add it later.

“As a manufacturer, we’re always looking for ways we can improve that time to market for customers, reduce touchpoints so that you can improve on automation,” Hutcheson says. “Presses just continue to get faster, which adds more and more bottlenecks. A lot of bottlenecks today are on the finishing side. Finishing manufacturers are looking at ways to improve their productivity because as presses get faster, the goal is to get off the press to the next step. You don’t want to lose the time you gained.”

Larry D’Amico, Durst Image Technology U.S., says his company’s one pass technology is highly automated. For companies in the corrugated segment, they are moving corrugated sheets to the press with no manual intervention, using conveyors. Everything is computerized. The company’s presses can print 3,000-4,000 sheets per hour because of their level of automation.

“We have people moving stacks, flipping stacks, jogging and aerating stacks, moving to the printer and to the cutting device with nobody touching it,” he notes. “It is incredible to see.”

Fujifilm’s high production presses can save job settings, and if a shop has clients that use them on a weekly, monthly or seasonal basis, the operator can set those jobs up using saved settings, including the type of media used, sheet size and thickness. The machine will call up all that information, which is helpful with the issues of labor shortage and turnover.

Fujifilm’s Onset flatbed printer has a robotic handling system that offloads onto a conveyor belt to take projects to the digital cutting system. It will also flip media when necessary, eliminating the need for an operator to intervene.

Job setup has always taken a lot of time, and Fujifilm has worked on automating just about every part of the printing process, including a vacuum bed that adjusts to reflect the sheet size so there is the correct spacing between the sheet and the print head for best image quality. The high production machines are also set up to automatically clean the print heads between jobs, which saves time.

Software

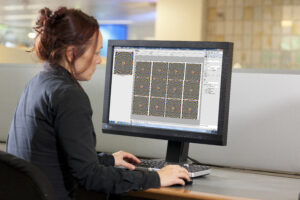

Workflow has improved dramatically and will continue to improve, Hutcheson says. Years ago, shops were set up with RIP software and a printer. That has changed dramatically. She says when people talk about workflow, they are not talking about RIP software. They are talking about a dynamic process that is trying to streamline and automate as much of the steps leading up to getting a job on the press as possible.

Because everything can be automated upfront, “it helps to catch any type of mistakes upfront,” Hutcheson says. “Talking about cost efficiencies, you want to find out about an error before it hits the press. Anything you can do pre-flighting, prechecking upfront helps to avoid costly mistakes.”

D’Amico says the term workflow can encompass so many parts of a printing operation, from automation tools on the equipment itself, like automatic feeding of materials through the machines, to the software that manages each job on the equipment.

![SoftSignage[84]](https://graphics-pro.com/wp-content/uploads/2022/03/SoftSignage84-1024x692.png)

“What we’re seeing is more of a move to low touch, whether through XML, Hot Folders, spreadsheet imports, there has to be automation for these jobs,” says Nick Benkovich, eProductivity Software. “At the back end, the challenge for a lot of folks in wide format is that substrates are so expensive if you lose square inches here and there, suddenly you’ve lost the profit on it,” he explains. His company’s workflow management software makes it easier to optimize jobs by ganging similar ones together to use substrates more effectively.

He says supply chain disruptions have contributed to substrate cost increases of 20% to 30%, influenced by higher transportation and energy costs and labor shortages caused by the pandemic.

“The front end, e-commerce portal reduces some sales costs and customer service interaction for more simplistic stuff,” Benkovich explains. For more complex point of purchase systems, companies save more because they can generate layouts and cutting files through the software. The software creates detailed layouts that look a lot like a game of Tetris as it fits as many jobs as possible on a particular substrate. Customers only have to enter all of the jobs they receive, the substrates they will be printed on, and when they need to be completed and the workflow management software makes the schedule and lays out how every job should be accomplished.

If a print shop handles all the window and floor graphics and shelf wobblers for major clients like McDonald’s or Buffalo Wild Wings that have hundreds of locations, eProductivity Software’s workflow solution can keep track of each location’s profile, from the number of windows and doors they have to the size of their footprint. That makes it easy to determine how many window clings or floor graphics to produce when a client decides to change its in-store advertising campaigns.

One of the biggest challenges facing high-volume shops is the number of orders they receive each week, many of them short runs. Managing the schedule of when jobs should be printed, cut out, and grommets added has become fairly tricky.

The company’s software allows shops to look at each job, when it needs to be printed, what it is printed on, which device, what substrate, and what processes need to come after, like cutting, die-cutting, sewing, or adding grommets. It will then create a dynamic schedule, sequencing the jobs for them so they can deliver each project on time.

If a schedule is already determined and a handful of additional rush jobs come in, the software will determine when those projects can be inserted into the schedule and help a company decide if a second shift is needed to meet the deadline.

Agfa’s e-commerce storefront allows even smaller graphics shops to be open for business 24/7, allowing them to extend their capability without throwing multiple resources at it. Its Asanti storefront simplifies the ordering process by automatically moving each job into the production process after customers enter their template into the system. The system automates the delivery of their print files. Instead of having to send them via email or Dropbox, Asanti Print Sphere receives the file that a customer puts in their folder and moves it to the press. The dashboard allows direct feedback from the press.

“When you talk about people dealing with very short timelines or trying to improve margins, our production dashboard tool provides an overview of ink and media consumption and printing time for each job,” Hutcheson says. If a couple of boards are kicked out for whatever reason, the dashboard tracks that as well.

Durst’s D’Amico says software options include customer interfaces, ones that do all the invoicing and billing, job definition, a whole ERP system and actual workflow does RIP and pagination before a job is output. Color management is another piece of the puzzle.

“If you are used to operating in an analog environment, digital workflows, adjusting files, pre-flighting files, many companies have never done that before and that is an incredibly important element,” he says. “If you don’t have enough foresight to hire the right people to handle that element, you are missing out.”