Behind the Letter: Raceways’ Roles in Channel Letter Projects

When using a raceway for an exterior channel letter sign, pay attention to the details. It will have a large bearing on the finished product.

For nearly 50 years, channel letters have been giving storefronts and brand names much needed exposure with their visibility and functionality. Improving throughout the years, this type of signage has advanced in the areas of ease-of-fabrication and installation. Made in plastic or metal, channel letters are dimensional, can be illuminated, and are mounted to the side of a building. The mounting aspect-the portion that exists “behind the letter,” so to speak-though seemingly simple from an outsider’s perspective, takes careful planning and precision. And it is the main topic that we will address in this article.

Traditionally, channel letters are mounted in a couple of different ways-either directly to the storefront’s façade (flush-mounted) or along a structure known as a “raceway.” Raceways are typically rectangular extrusions that can house electrical components and hold channel letters in place. Though, as some sign shops will attest, the process of including them in a project can be much more intricate than it might appear.

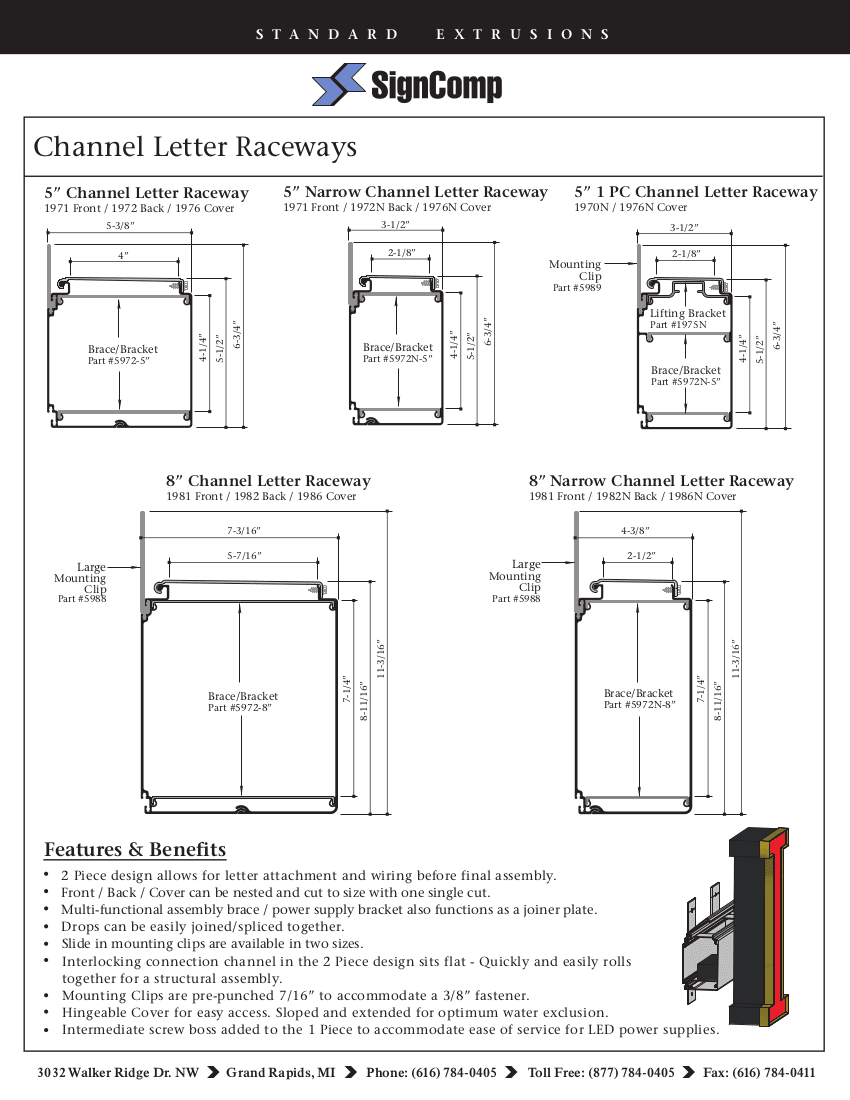

“We use extruded raceway by SignComp and it comes in sections, a front section, back and lid,” explains Dave Brazzell, president of Brazz Specialties Inc. “We made a fixture to hold the front half of the raceway in the CNC router and set it up to drill the screw holes and route the electrical pass-through holes. The backs go to the fabrication area and are joined to the letter returns, loaded with LEDs and are ready to install on the raceway. The raceway goes to the welding area and is welded together and prepped for paint. The raceway is painted and sent to final wiring where the letter is mounted to the raceway and the wring is completed.”

Perhaps, there is more to this component than meets the eye.

Elements of Installation

The installation of channel letters to raceways is a process that involves several factors- from depth, to size to electrical capabilities. Suppliers and sign shops should have synergy as they determine the best options for end users.

“Gemini works with the specifier to determine the ideal location of mounting hardware, electrical connections, and even the position of the UL labels to optimize the final appearance of the sign installation,” shares Wayne Meyer, product manager, Gemini Inc. “Determining the desired end result at the beginning of the project helps keep everything seamless.”

From the sign shop perspective, that means anticipating any changes that a customer may want to make to the sign in the future and planning for the most successful project possible.

“We suggest that each letter that is similar and has the exact same hole pattern,” states Brazzell; for example, the letter “A” in one size could interchange with any other letter “A” of the same size. “When the letters are attached to the raceway, confusion is minimized.”

“Once we finalized the art file for our letter backs,” he continues, “we add our screw holes and electrical pass-through holes into the program file so that the holes are saved in case a letter might need to be replaced down the road, the holes will match. The letter backs are cut on the CNC router.”

Regarding the actual specs of a project, there are some guidelines in how to determine depth, size, color and other elements of a raceway-and the channel letters that are used with it. This may have a significant impact on the installation process.

Depth

“The depth of the raceway is limited to what you can fit your hand into,” says Tony Wheeler, president of SignMonkey.com. “Our standard depth is five inches; this gives the builder enough room to get his hands inside to make connections. It also is large enough for technicians to make future repairs in the field.”

The raceway depth is also important when speaking to the electrical components that fit inside the raceway. Wiring is protected by the raceway from any severe external conditions like heat or moisture. And end users need to be certain a storm, for example, will not compromise the quality of the sign.

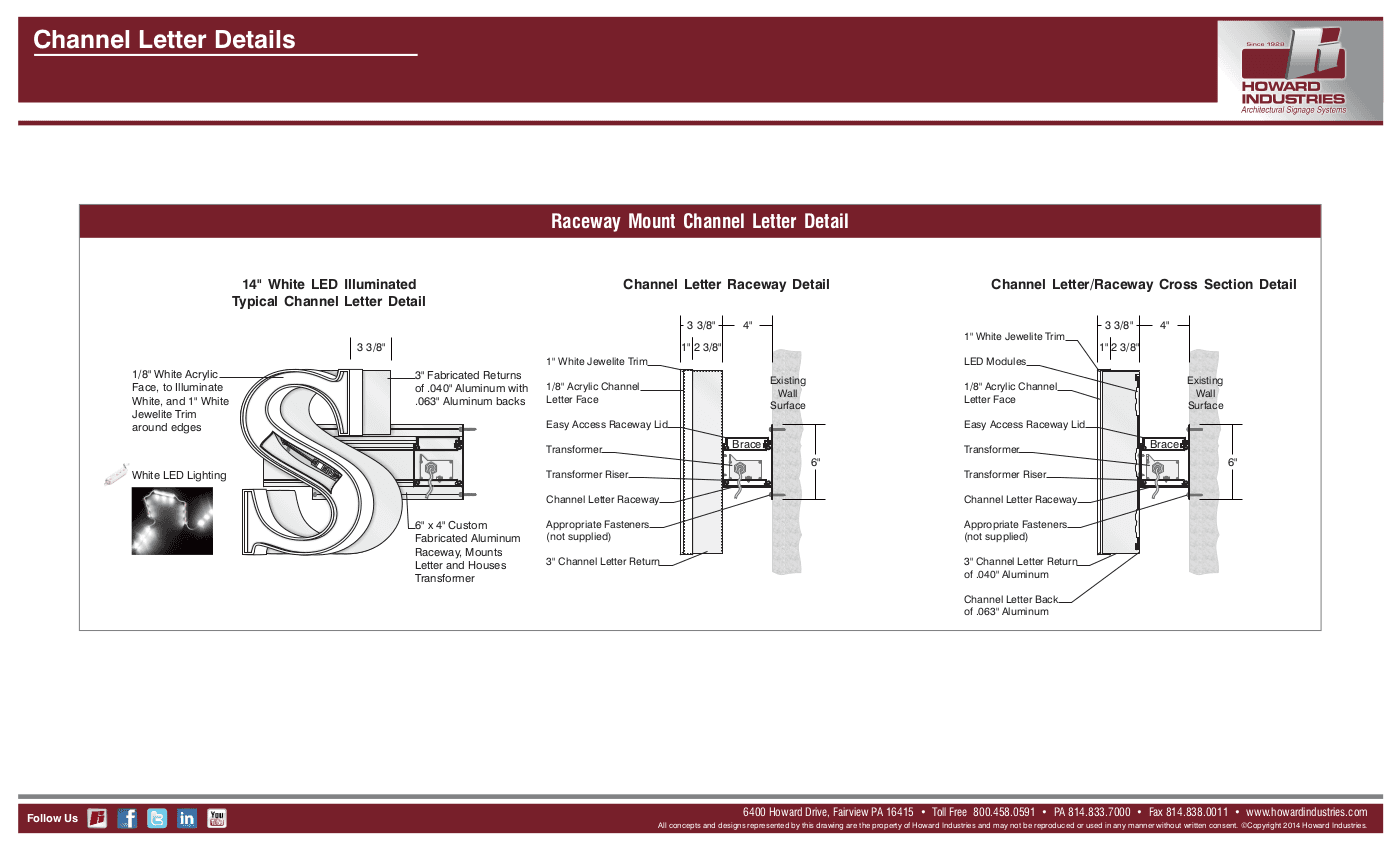

“The protrusion distance (of our raceways) is four inches, which you will see in our literature,” says Jeffrey Stewart, vice president of sales for Howard Industries. According to the Howard Industries site, the four-inch extruded raceway includes “an integral mounting flange, integral transformer heat sink and mounting platform, and a water-resistant hingeable cover that allows easy access to internal components.”

Very closely related to the depth of a raceway is the size, which will impact the accuracy and effectiveness of the total sign.

Size

“Making consistent size raceways and putting your power in the same location each time will help the installers to figure out where to drill the mounting holes,” says Wheeler. “We build our raceways in no longer than 10-foot sections. This makes handling and installation easier.”

For extra-long raceways, the job can present some challenges. However, there are methods to simplify the process, so sign makers aren’t struggling through the install stage.

“(We) size continuous lengths up to 20′, then we butt splice as additional length is required,” explains Stewart.

Warren Sciortino, owner of LetterFab LLC, emphasizes that long lengths of raceway can be sized to fit the project. “They are cut to the size needed,” he says, adding that raceway is available in 24′ lengths. He continues, “The length of the raceway will depend on the length of the letters. On the standard raceway, they come with a sliding bracket top and bottom. This will make the install easy. We also build custom raceways any size the customer wants.”

Another consideration with size is how the materials are being shipped to site.

“Shipping a 10′-long raceway section is easier to crate and much less likely to get damaged,” Wheeler states. “Our raceways are always 10′ or shorter-length sections.”

Color

With raceways, color selection can be an option if desired. In some circumstances, end users will want to “hide” the raceway’s presence behind the letters.

“The sign company will provide the color of the painted custom finish to match the color of the wall it will go on when they order the sign,” Sciortino says.

With any project, color matching is a big deal in the sign industry. For raceways, these structures are being installed against several different backdrops-brick, cement, wood-and should have a fluid appearance within the environment by matching that backdrop.

“We offer custom color matching, which is critical to a good-looking, final, finished look,” tells Stewart. “Raceways must match the wall color, or you will not be left with a professional looking job.”

Going into a little more detail, Wheeler says, “In the ideal world every customer would give you a Sherwin Williams color number. This seldom happens so we match to a Sherwin Williams book or other colors that Matthews paint can match formulas with.”

Through experience, sign makers will learn to distinguish which colors are best fit for the raceway. Wheeler gives a tip that, “we always choose a color just a shade darker than the wall color for the raceway color. This helps the raceway to disappear. If you choose the exact color of the wall the raceway will look brighter, since there is a shadow below and between the letters.”

Materials

As with the actual channel letters on the sign, the raceway should be made strong enough to endure through many years.

“Gemini’s fabricated letters can be made with either aluminum or stainless steel,” says Meyer. “Stainless steel has the benefit of a wide variety of finish options-painted, brushed or polished finishes as well as several colored titanium coatings.”

Regarding material for the raceway, there are some options, however according to Stewart, “Extruded aluminum is the best (because) it’s an excellent heat sink to dissipate heat from the power supplies.”

Wheeler agrees, saying that “We build all our raceways and letters of aluminum. We seldom use steel for anything other than center pole mounted signs. Steel is just too dirty to work with. Aluminum is easier to fabricate and paint.”

When painting aluminum, it’s important to note the appropriate steps to achieve the highest quality. Brazzell suggests, “Extruded raceway material must be primed and painted before install. The letters come in pre-finished colors and usually are either five inches or three inches deep.”

The Latest

As channel letters have progressed through the years in every aspect from fabrication to illumination, raceways have done the same. In fact, the very changes that have occurred in channel letters have provoked improvements in raceway technology.

“With the new LED illumination technology that has swept through the sign industry, Howard Industries saw the need to develop a slimmer, low-profile lighter-weight, raceway design with integral mounting flange,” explains Stewart. “LED letters are lighter construction, so it was natural to re-design the old bulky raceways used with neon letters.”

By creating a thinner raceway option, it also resolves the need to keep the raceway hidden from the main focus of the letters, according to Stewart. However, hiding a raceway can be done through another method as well.

“If the customer would like to hide the raceway, we can make a background,” says Wheeler. “This is a sheet of ACM that is cut to create an outline around the letters. This hides the raceway and can make a contrasting color for the letters.”

Other improvements in raceways include more advanced and automated aspects.

“Standard on all of our products is a three-way switch and a photo eye,” shares Wheeler. “That way if the customer wants to use the photo eye it is already installed. If they choose not to use the photo eye, they can switch the sign to on constant. Of course, the third position is off.”

Still, even in traditional raceways, some of the biggest advancements remain focused on efficiency and ease-of-use for the sign maker.

By using aluminum materials, for example, the lighter weigh material, “can extend custom letter or logo height up to 120 inches in a single piece,” Meyer says.

The ability to adjust the size of a letter, and thus a raceway, brings better branding and visibility to the end user.

“The height of the raceway is determined by the height of the letter,” Wheeler says.

Tips with Codes

When dealing with any type of electrical or channel letter project, there are sure to be rules and regulations to follow. Sign makers will want to educate themselves on certain codes to be sure they are in full compliance.

“(Codes) will depend on the city, and every city is different,” Sciortino says. “Some require engineering designs showing how it is attached to the wall-they require wind load. Each raceway is UL and they have a disconnect switch with a UL sticker.”

Wind load is a consideration that will often arise. City officials need to have confidence that the signage is secured safely and is structurally sound. Any extreme weather condition is a potential threat to channel letter signage, and wind plays a part in that scenario

“There are some municipalities that require engineering for wind load,” explains Wheeler. “This can be expensive and must be part of your price. We always get permits before building anything. You are taking a big chance if you build a sign without first getting a permit.”

To reiterate, manufacturers and sign makers should both be on the same page to ensure the end user is satisfied with the project. This is especially imperative when incorporating every channel letter sign element-the letters, the raceway, the electrical components and any other additions.

At Gemini, “letters can be provided with UL-Certified LED packages, and the letters will include UL-Listed Sign Section labels for all sign bodies and power supplies,” Meyer says. “These components are used by the sign installer, when installing the letters and raceway. We count on their expertise and awareness of local electrical codes and the requirements of the local inspector. This partnership with our customers is mutually beneficial-they are the experts in installation and Gemini is the letter expert.”

Through the history of channel letter signage, there have been several companies, experts, consultants, locations, and customers involved. Each time a project is completed, this area of the sign industry seems to advance. Looking behind the letter can lead to some very thought-provoking questions, and it’s the reason that a seemingly simple component, such as a raceway, is as important as any other element.