The apparel decoration industry continues to evolve and innovate while using some of the same applications it has used for decades. Do you have 1,000 T-shirts you need printed? Screen printing is your most economical choice. Do you have a small order for apparel? Direct-to-garment (DTG) printing may make more sense. Want something a little more professional or luxurious? Consider embroidery.

The newest technique, which has been gaining in popularity, is direct-to-film (DTF) printing or direct-transfer film. That is the process of printing a design onto heat-transfer film that is then applied to a garment with a heat press. What makes the technique so popular is that companies that know they will need future apparel with the design can proactively purchase additional transfers that can be applied at a future date.

Screen printing

Screen printing has been around for hundreds of years, but it wasn’t until the 1980s that the process became more automated. Now, screen printing is accessible to home-based businesses as well as commercial print operations.

Screen printing is a process in which ink is forced through a mesh screen onto a surface using a blade or squeegee. A stencil blocks the areas that should not be printed. Each color requires a separate stencil and screen, which can be time-consuming.

M&R Printing Equipment makes several automatic textile presses that allow screen printers to operate in places that couldn’t accommodate them in the past. These oval automatic presses are modular, enabling users to configure a single press with more than 50 printheads and do multiple screen-printing jobs simultaneously.

“Screen printing is like the standard for a lot of garment decorating,” said Cody Corsano, print applications manager for M&R Printing Equipment. But the invention of digital inkjet and DTF have started cutting into its market share. That’s why the company has expanded its offerings to include DTF and DTG printers.

“The thing with screen printing is it is very process-oriented. If you are not following the process correctly, it is hard to get a commercially acceptable print,” Corsano said. “But in my opinion, it is one of the most versatile ways to print.”

Screen printing can be applied to any type of fabric because there are inks in the market that are specifically formulated for them.

It also has low setup costs. Once a silk screen stencil is made, it can be used to print a large number of items, lowering the print cost per item. Screens are inexpensive and can be reclaimed and reused for hundreds of prints. Another benefit is durability. Screen printing lays down a thicker layer of ink that keeps prints from fading as quickly in direct sunlight.

The cost of entry is very low. Individuals can get into screen printing for a few thousand dollars, including a small press, ink, tools, adhesives, screens, cleaning supplies, and a small printer to make the stencils. Because screen-printed graphics need to be cured, a small flash dryer or heat gun can do the job.

Screen printing works best for simple designs. If a client wants a photo reproduction, DTG or DTF is the way to go. It also takes time to make the screens, which can become cost-prohibitive for smaller print runs.

Screen printing can also be used to print designs on film, which can be transferred to apparel using heat.

“Everybody is saying digital will kill screen printing, but screen printing is still here. Now they are saying DTF is going to kill screen printing. It all depends,” Corsano said. “To say it is not shifting would be just as crazy.”

Direct to garment

DTG printers were a game changer when they were first introduced in 1996. Most of the first DTG machines were modified Epson paper printers. Epson is still a major player in DTG and DTF, offering smaller entry-level inkjet printers for as little as $7,000, and more expensive equipment that is purpose-built for textile printing, including the printheads.

DTG is “really attractive if you are printing on 100% cotton,” said Karl Tipre, owner of DTG Connection. “It breathes, is a soft hand, and is a quick direct-to-print process.”

DTG ink and print quality are hard to beat, he added, because they create nice, vibrant prints. To print directly onto a shirt, it needs to be pretreated. Print shops can pretreat their own shirts or purchase pretreated shirts for 60 cents to $1 more, which allows them to print anywhere they want. “It smooths out the DTG process,” Tipre said. “Then you don’t have to buy a new, expensive treatment machine, which is one more thing to clean and maintain. I’m a big fan of that.”

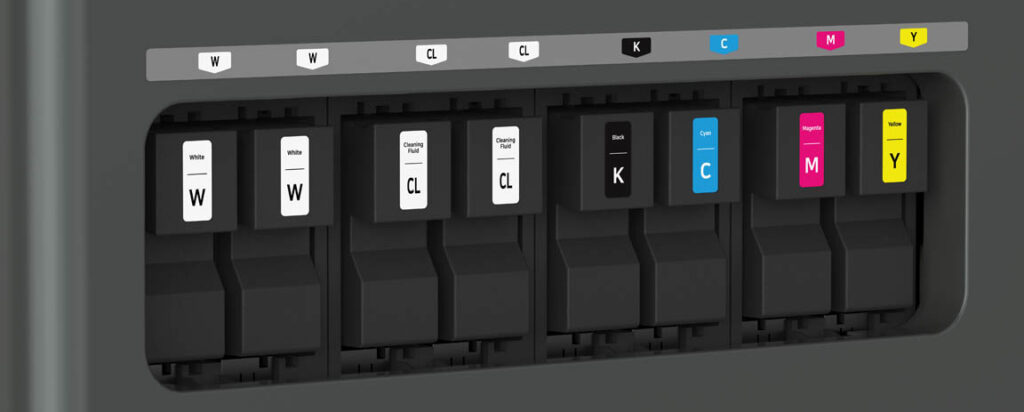

DTG printers use water-based pigment inks, which is a clean process. Prints do need to go through a heat press to set the design.

Digital printing is faster than screen printing. Once the design is uploaded to the printing software, all an operator has to do is press a button and watch it do the job. Many DTG printers can also be used for DTF.

Direct to film

DTF is one of the most economical ways to enter the apparel decoration market. DTF printing systems range in price from $5,000 for a desktop version to $100,000 for a high-volume variety.

“That’s pretty cheap compared with setting up an entire screen-printing operation,” said Greg Farmer, a sales executive at Insta Graphic Systems.

Just about anyone can get into DTF printing, all it takes is an inkjet printer that uses both color and white inks. When the design is printed on the transfer film, it starts with the colors, followed by a layer of white ink. A layer of powdered adhesive is placed over the top of the design before it is heat-cured.

Once the transfer is cured, it can be immediately applied to a textile using a heat press. Roll-to-roll printers make the process go much more quickly.

One of the downsides to DTF is that the powdered adhesive can get everywhere, so operators need to use gloves and wear a mask. It is also a good idea to place the printer in a well-ventilated area. Farmer said he would not want to put a DTF printer in his house.

Insta Graphic Systems also sells screen-printed heat transfers, which produce a better-quality print than DTF, he said, but are messier and more time-consuming to produce.

“That is where DTF is finding its niche,” Farmer said. And although DTF is not quite at the quality of screen-printed transfers, “It is catching up pretty quickly. I would say it is still not there yet with durability compared to screen-printed transfers, but it won’t be very long” before it improves, he said.

Some big-name printer manufacturers are starting to make DTF printers, including Epson and Mimaki. Many shops like the process because it is versatile, and the transfers can be placed on many different fabrics.

“It boils down to the adhesive,” Farmer said. Some substrates require a different adhesive to work effectively. “People who know what they’re doing will experiment with different inks and adhesives and will find their own formula that works for them whatever the customer application is, whatever it might be.”

The upside of DTF is that the transfers can be printed on demand and the process only requires one operator, who doesn’t have to babysit the machine. “Most systems out there can run autonomously,” Farmer said.

“Some of the people getting these systems are able to take on jobs they were not able to do before,” he said. If a shop is working with a brand that is selling custom prints on its website, the seller doesn’t have to order 500 shirts at once. It can order single prints for the same cost in materials per shirt as if they ordered 10,000 shirts, Farmer said.

Shops can get into DTF for less than $3,000. All they need is a heat press. They can order their DTF transfers online or purchase their own DTF printer.

Embroidery

Embroidery has always been a popular apparel decoration technique for baseball caps, apparel with college teams or sports logos, or corporate wear.

“I don’t see it slowing down any,” said Bob Stone, VP of sales for Barudan America. “It’s a small industry as industries go, but it has still been pretty popular in the years I’ve been here. I don’t see it slowing down, especially in the states.”

Just about any article of clothing can be embroidered. The only necessary improvement is the type of backing that is used. Thinner fabric will need a thicker backing so there is something solid for the embroidery needles to work through.

It costs about $16,000 to get started in the industry and there is a slight learning curve, Stone said. “Embroidery is not hard to learn, but it takes a bit of time to become an embroiderer,” he said. “We can teach you to operate the machine in an hour, but like screen printing, there are little nuances you need to know for your work to come out good.”

Stone added that, like anything else, “You learn by making mistakes along the way.”

In the past, shops would have to take classes in person, but online training makes it easier for people to get up to speed quickly, although there is still a learning curve, he said.

It is important to use good thread and good bobbins. “If you try to buy cheap thread, cheap bobbins, or cheap backing, you will get poor results,” Stone said. “Start with a good machine, good supplies, and 99% of the time, it works out really well.”

The downside to embroidery machines is the software. If a design is not digitized correctly, “You will have a mess on your hands. You can get away with more sloppiness in screen printing if it is not as precise,” he said.

Embroidered designs have to be built in a particular way because the design has to be sewn in a particular order or sequence, or the design will be out of registration or look bad. The general rule is that everything starts from the center of the design and is sewn outward. You can’t just produce the design by sewing left to right because the needles will begin to push the design to the right. It will pucker the material, especially if incorrect backing material is used.

Monogramming is another embroidery technique that goes in and out of popularity. For a while, women wanted monogrammed handbags, and men wanted monogrammed shirt cuffs or collars. Where embroidery still reigns supreme is in the personalization market. People can go online and order personalized apparel, backpacks, or even Christmas stockings.

Out of the four apparel decoration techniques, the quickest and cheapest option for entry into the space is DTF. The learning curve is less steep than some of the other options, and it can be used to personalize objects, such as mugs, as well. If a shop decides to purchase an apparel printer, a small DTG/DTF hybrid is a great option, as it doesn’t take up much space or require a ton of cleanup afterward. Screen printing will always be an option for larger apparel orders and simple designs, and it is fairly easy to master. Embroidery makes a nice alternative to printing and appeals to a different subset of clients.