For many new to the interior sign world, the mere mention of the Americans with Disabilities Act (ADA) or wayfinding may as well be Greek. The whole checklist of requirements on the surface can appear overwhelming, let alone all the different construction types available today. For most of us, the manufacturing of these types of

signs is outside our wheelhouse and beyond our abilities to create in-house.

These types of signs are not only mandatory by building codes but have a significant impact on an organization’s branding and environmental-themed graphics, so you get an idea of the size and profit potential of tapping into this market.

Your existing customers likely already have a need, and new customers will also have that same potential. Yet a lot of shops pass on the opportunity largely due to a lack of knowledge and understanding. That is where having a valuable wholesale partner for interior architectural signage enters the picture.

Finding your way

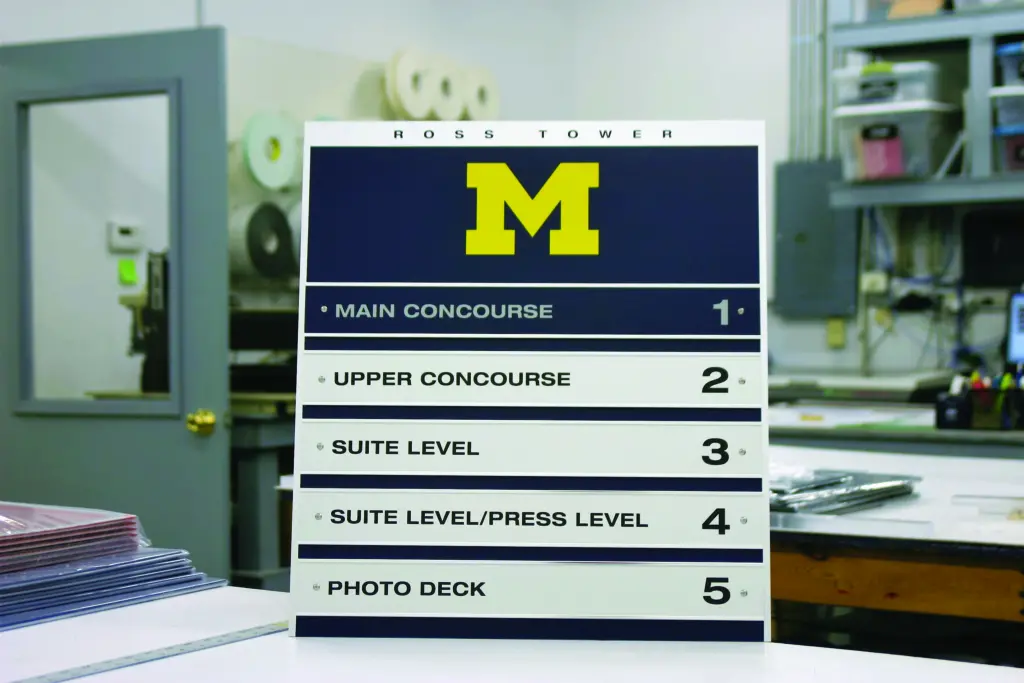

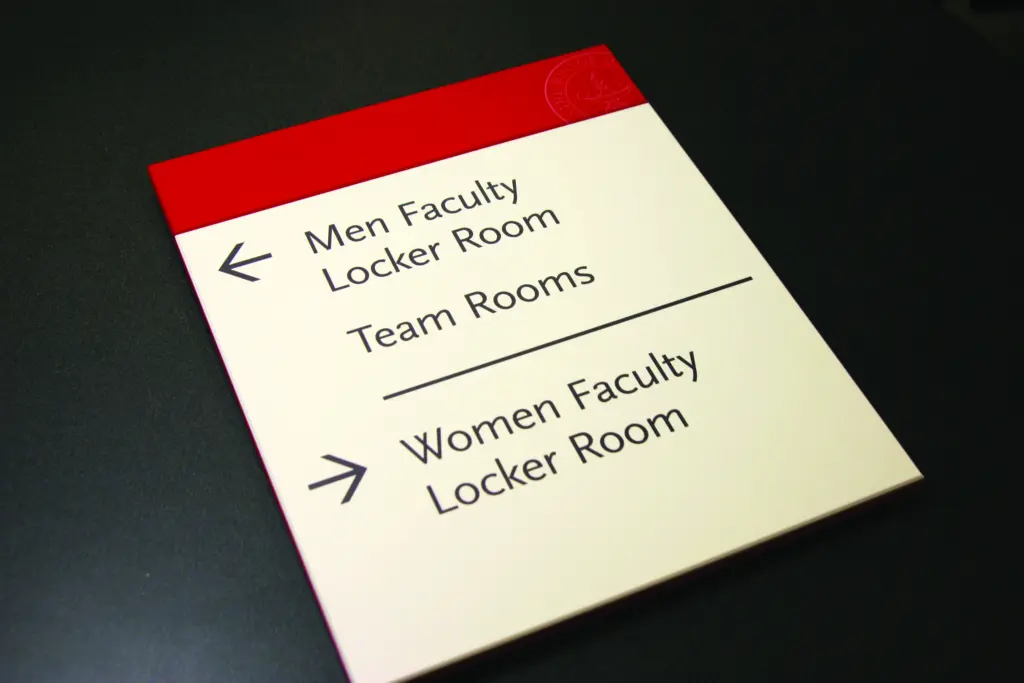

Don’t stop at the ADA-compliant code sign when your customer comes in asking for help. If the request is for something large like a school, office building, or multifamily project, don’t forget to ask about the wayfinding! Your imagination is the limit (well, your client’s budget may have some constraints).

Most of this type of interior work revolves around new construction or remodeling. This is the perfect time to be talking about the impact of signage and graphics to complement that construction investment, and, when appropriate, help announce and promote your client’s brand.

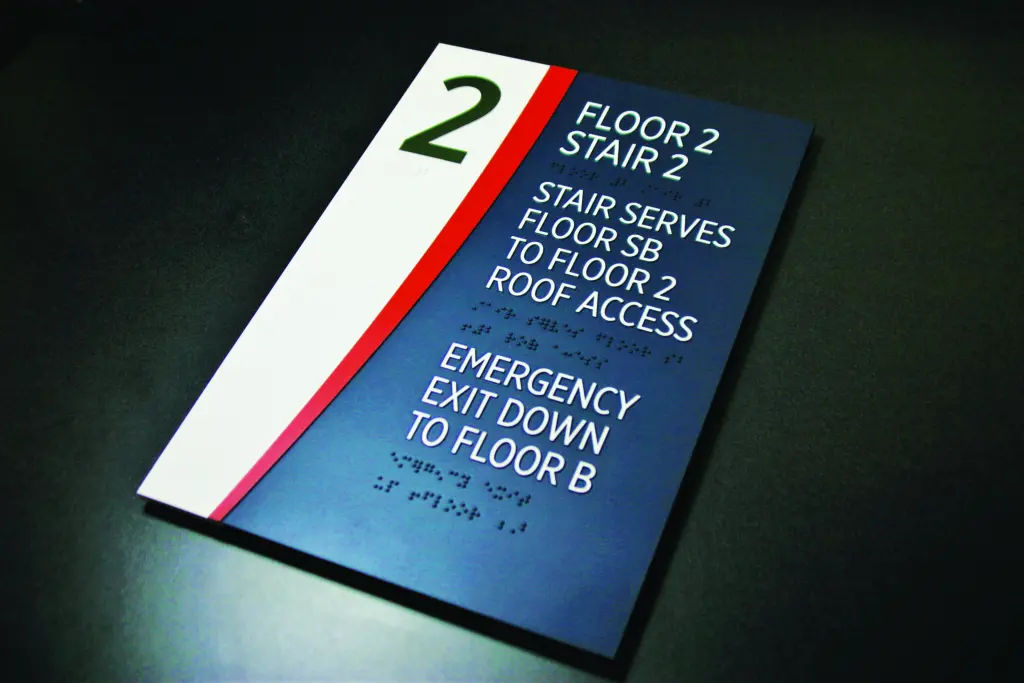

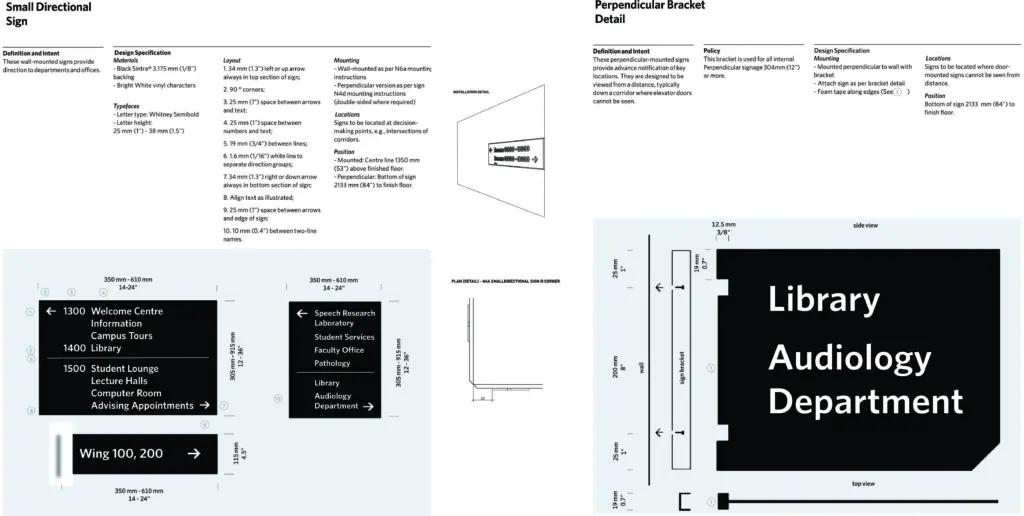

Most wayfinding signage consists of direction-oriented signs. In most projects, these do not have to be fabricated with raised copy and Braille. Doublecheck with specific local ordinances for code-related signage to confirm. Often, your wholesale contact may have already done work in the area of your project and can advise accordingly.

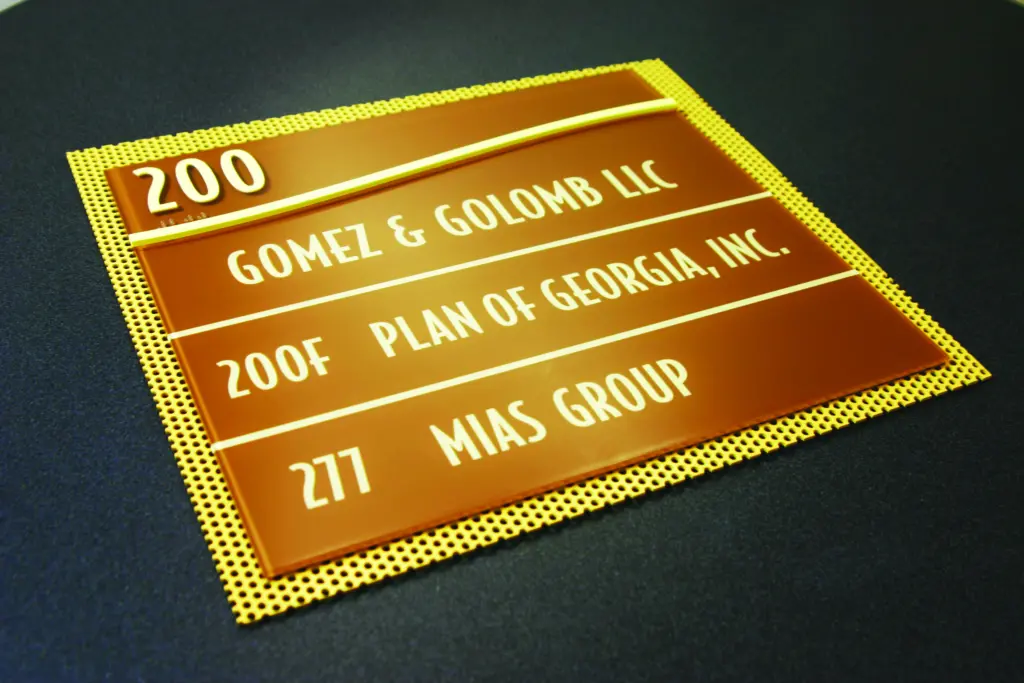

This is a prime upsell to tie the ADA sign family types with branded type, colors, and background design into wayfinding graphics. This could include directories, directionals, rules, and amenities signage. Your client may already have a message schedule or list asking for these signs in addition to the ADA-compliant signage.

If you are in a competitive quoting situation with other companies, remember this: if you quote your wayfinding signs with raised copy and Braille, you could outbid yourself with a competitor that prices flat backgrounds and cut vinyl.

Since most wholesale companies charge using a square-inch formula for ADA signs, the price will differ. For example, on a large directory or directional sign, the increased costs can be significant. For some clients not concerned with budgets and an eye for detail, they may want to keep the signage consistent with raised copy and Braille. It’s your job to point out the difference and present the best possible options.

This is a great opportunity to bring some of an overall project in-house, as most shops can handle the simpler fabrication of wayfinding signs and are confident printing and installing wall coverings and glass-partition vinyl graphics. If you are not comfortable or confident, you can bet your wholesaler can help produce these graphics or refer you to someone else that can in the case of vinyl graphics and wall coverings.

If the whole interior architectural world seems a little overwhelming from a design standpoint, don’t discount reaching out to an environmental graphic designer. Contact your local chapter of The Society of Experiential Graphic Design for contacts or ask to see samples of projects you like from your wholesaler and ask if they could refer you to a designer.

When complete, all of this is work is seamlessly incorporated into creating the overall interior environmental graphics package. If you’re tech-savvy, the potential for digital displays and digital directories also exists.

On most signage programs, the scope of work for a complete interior sign project can easily rival the overall exterior sign budget. There is a lot of potential to take advantage of with as much or as little involvement as you care to get into in this arena.

The ABCs of ADA

Entire volumes of books have been devoted to ADA compliance, and many signage specific have been published for further reference. Bottom line, there is an overall benchmark of compliance for ADA signs and then there are additional requirements dictated per state and even individual municipalities.

Some of this can be clarified by zoning officials, but a good wholesaler will have a great deal of experience and can become an instrumental partner in navigating these waters.

As with working with wholesalers for exterior signage, your interior contacts are providing more than just product, so be open and willing to ask for assistance. Remember, they also want the experience\ of working together to be positive and profitable so that you return for your next project.

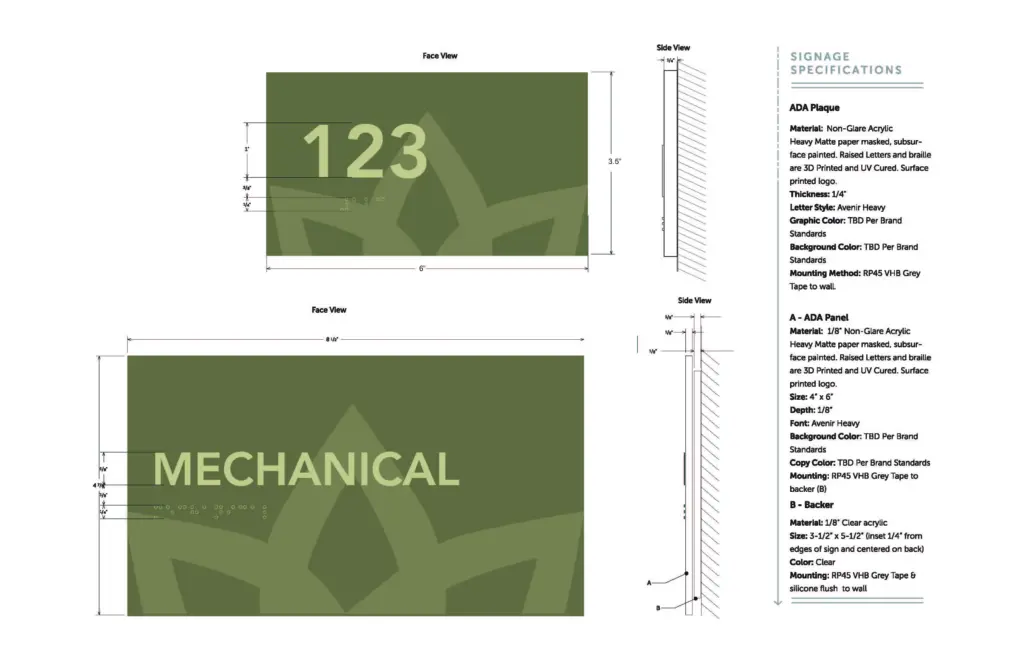

There are two primary types of ADA signage: integral and additive. Integral is the manufacturing process of creating the raised lettering and Braille by removing the material in the substrate — some refer to it as subtractive production. This is achieved by exposing a special PETG plastic product to UV light, which melts the substrate background, or CNC routing or sandblasting away the background in other substrates. In the case of thermoforming, this is done by pressing acrylic into a mold to recess the background, leaving copy and Braille raised.

There are two common additive processes. The first is traditional-cut letters and pictograms applied to a substrate with strong VHB tape and having the Braille beads adhered to CNC-routed half circles in the substrate to accept the bead.

The second is a relatively new process to the market and is what is sometimes referred to as 2.5D additive printing. This utilizes the technology of flatbed UV printing to print dimensional, raised copy and Braille to an appropriate substrate.

These are all ADA-compliant, so the big question is why so many options? Cost, durability, frames, and decorative options come into play. For example, the photopolymer product is very popular in the education market. The signs are integral in construction, making it very difficult for a bored student left in the hallway to pick the lettering and Braille off. However, since the photopolymer process uses UV light to subtract the background, these signs can literally melt in direct sunlight in exterior applications.

There are many other reasons one product is preferred over others. In new building construction, an architect’s specification and drawing sheets are referred to as preferred construction and a project and may also call out the need for specific framing systems.

This is where your wholesale partner can provide years of experience in helping you navigate the choices and make educated and experienced recommendations. That may sometimes involve “substitutions” in those architect’s specifications. Some of those have been copied and pasted for decades and were written well before some of the technology used today was even invented.

Your wholesaler should easily be able to provide you with shop drawings and product samples to propose your value-engineered substitutions to called-out specifications and drawings. For example, that same school mentioned earlier may accept thermoformed acrylic for exterior ADA signage over the specified acid etched magnesium or zinc for exterior applications. It’s just as durable, cleaner for the environment, and often less expensive; it may very well be an alternative to the interior as well. Thermoformed signs were not around at the time the specifications were written. Your wholesaler has likely seen it all and is glad to pass on those learning experiences.

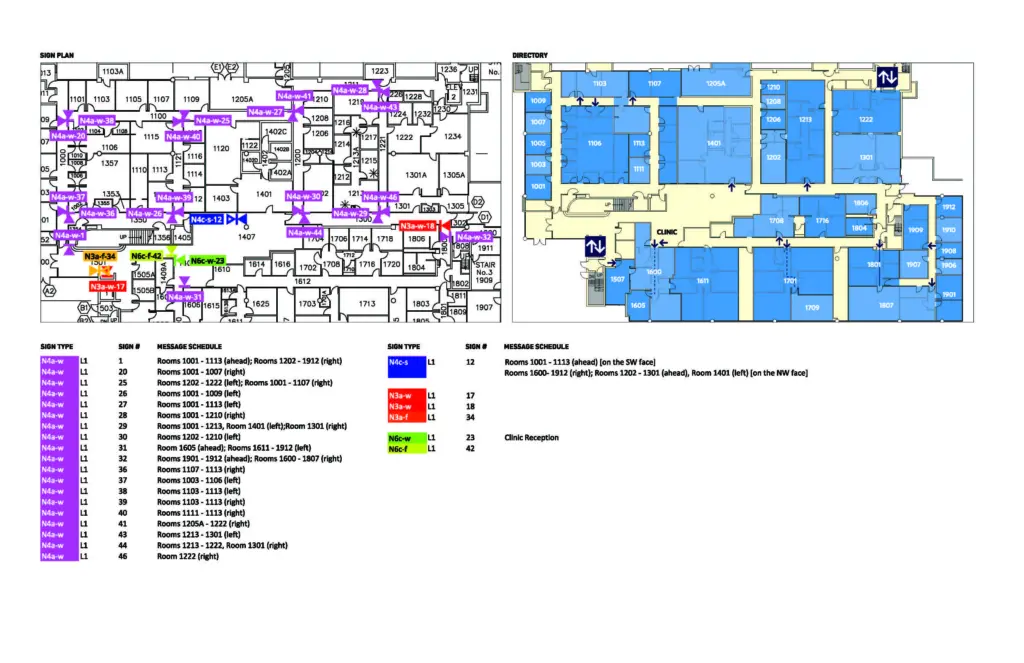

educational facility. Note that most wayfinding of this type does not require raised copy and Braille unless noted by a unique local ordinance stating so or if the client really wants the exact

finish as ADA required signs in the program. (Drawing provided by James Dean 130)

Show me more

To further explore both the products and services a good wholesaler can provide, I spoke with Bill Baker, president of Park Place Sign Systems Inc. in Hannibal, Missouri.

“A good deal of our most successful customers knew very little about ADA signage or of the huge potential of the interior architectural signage market initially. Once they got a few projects under their belt, it became second nature to tie the interior program to the exterior of the project they were initially asked to quote,” Baker says.

Baker and his team accomplish this by educating their customers on ADA basics. “Interior signage can be the first time our customers are exposed to architectural specifications and drawings, floor plans, and sign schedules. It can be a little overwhelming, but we can help them navigate through the paperwork and show examples of similar projects that utilize many of the sign types and construction options we offer at Park Place,” he says. Baker was quick to add that legitimate wholesale manufacturers do not compete with their clients by directly bidding on projects to an end user.

There are many advantages to using the experience of vetted wholesalers for companies entering the interior market. A wholesaler should be very familiar with not only all the products they provide, but all products and trends in the industry and be confident to review project specifications and provide signage that meets the end customer’s needs. And, when necessary, provide value-added suggestions that lower costs and possibly speed production without compromising the look and functionality of the sign products.

That experience can also be helpful in assisting with installation questions that involve mounting methods, heights, and locations to provide a completely code-compliant application.

“When drawings and specifications are provided for pricing, we carefully review and quickly provide a quotation that meets the project requirements at a competitive price. When a quote becomes an order, we again review the project and request any needed info to begin production. A firm delivery date is assigned at the time of final approval and sign-off from our customer. We then work closely with our customers to provide products when needed to meet scheduled installation dates. If by any chance a problem occurs, we will do whatever is necessary to correct the situation and stand behind our products with a full five-year warranty,” Baker says.

Interior projects do not require freight for shipping. Most product ships in easy-to-handle boxes. A good wholesaler likely has installation experience, and they will have products clearly marked, packed in a logical manner, and ready to go out of the box at the jobsite.

Ask to have one packing slip per box and you can be confident to take the package direct to the project site or drop-shipped to your installation team. Confirm with the wholesaler to have the sign prepared with double-stick tape and they will take care of that as well, shaving hours of shop time to cut, apply, and repack. You don’t want to have that process done in the field by your installers.

You control as little or as much of the process as you care to be involved in. While most companies will have a little wiggle room to give a rush, don’t bank that it can be done and prepare for a backup with temp signs if building occupancy inspections are needed by your client. Good wholesalers can often help with temp solutions.

The interior architectural signage has evolved and grown. It is an integral part of the overall environmental graphics of a building. ADA is a great building block to create a consistent and themed foundation. Creating a partnership with a trusted wholesaler can eliminate much of the learning curve. Remember, the goal is to create a win-win situation on your first project and each one after that.