A Place for 3D Printing in Signage

Although limited now, 3D printing has a bright future for the industry.

3D printing continues to evolve, and as it does, sign makers are figuring out ways to incorporate the technology into their business. Although the technology is exciting, it’s not always the most practical for signage applications. However, because of the crossover for architectural production and the graphics industry, there are some unique ways 3D printers can be used to create memorable displays.

One manufacturer that is having an impact on the signage industry is Israel-based Massivit Printing Technologies, which offers two of the largest 3D printers in the industry, the Massivit 1800 and the Massivit 1500.

The founder of Massivit 3D started out in wide-format printing and eventually was involved with a company that operated in the traditional 3D printing space. He wanted to marry the two technologies, and Massivit 3D was born.

“The whole idea was that if you look at grand format, the large-format space today, it is very crowded and very commoditized,” says Kevin Sykes, president of U.S. operations at Massivit 3D. Companies come up with inventions, they mature and at some point, become commoditized where the margins are slim, and competition is high. That doesn’t exist yet in the 3D space, he says.

“Up until Massivit, no one in the visual communication space could print fast enough or large enough to address the needs of the market,” Sykes says. “The ultimate idea is to bring back the opportunity to differentiate yourself, command higher margins for products you provide and still fit within the needs of the market.”

He says that when Massivit 3D shows up at a trade show with its 3D-printed elements, they command four times more stopping power than traditional 2D and five times more staying power, engaging or interacting with whatever that 3D element is.

Massivit customers say that they are not only selling 3D prints and 3D models, but their 2D business has grown as a result of having a 3D printer, says Sykes.

The Massivit 3D 1800 has a maximum printing volume of 57″ x 44″ x 70″.

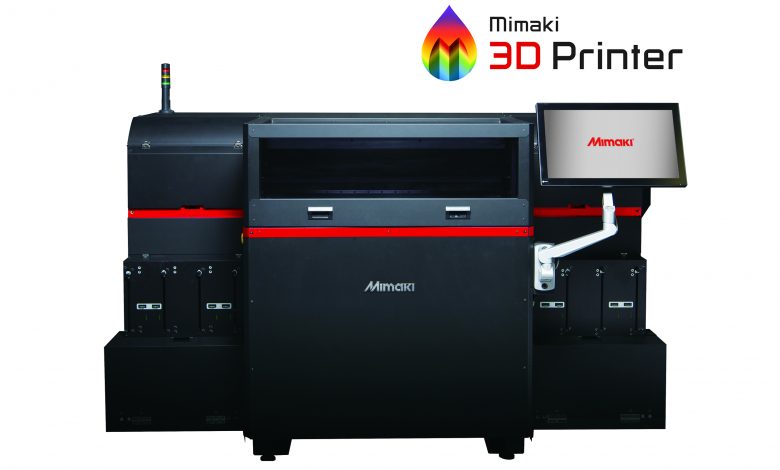

“For us, most of our work is a good bit smaller than that,” says Josh Hope, senior manager, engineering projects, for Suwanee, Georgia-based Mimaki USA. “We focus on photorealistic output.”

But for other 3D printer manufacturers, the signage market hasn’t taken off like they thought it would. Mimaki USA, for instance, thought its full-color 3D printer was going to impact the signage market, but instead it found that signage is a secondary consideration for shops that are using it for completely different purposes than what Mimaki initially envisioned, like product prototyping and visual assessment of design.

“We haven’t seen much adoption of 3D printing in the signage market in the U.S.,” says Hope. The Japanese market has been much faster to adopt 3D printing, he adds.

In the U.S. it comes down to the cost of equipment, cost of print and the amount of time it takes to make a print.

“A lot of times people are looking at that and other technologies out there, whether it is CNC or styrofoam carving or things like that that might make more sense,” he says.

Mimaki’s full-color commercial 3D printer, the 3DUJ-553, can output more than 10 million colors.

As far as signage goes, Hope says that Mimaki’s machine works better when it comes to making scale models of a sign before working on the finished product. The company’s 3D printer is 20″ x 20″x 12″, which means it can be used to make bigger 3D models but they need to be layered together.

“For the cost and time to do that, it is probably not, at this point, the most cost-effective way or the most efficient way,” he says.

Hope adds that everybody in the signage industry is looking at 3D. They want to see where it is going to go.

“It’s definitely going to play a part in our future the same way LED signs crept in years ago. I expect 3D will be the same thing. We are very much on the edge of the adoption curve. People are interested and excited about the technology, but where does it make sense to use 3D as opposed to other technologies out there?” Hope says.

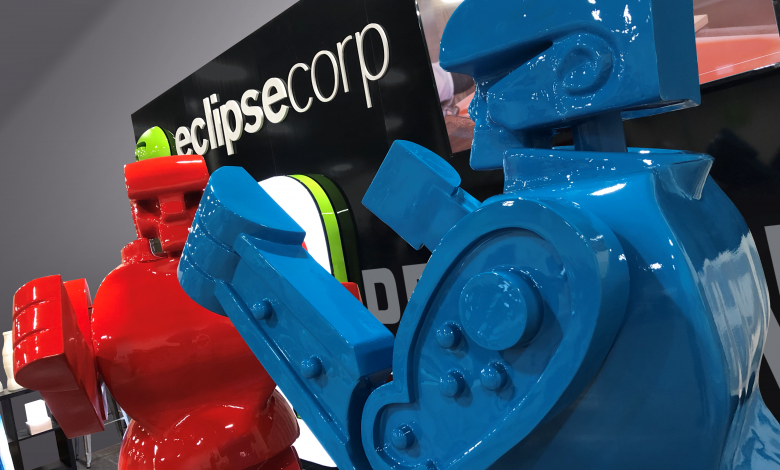

Jeff Burt, owner of Eclipse Corp. in Gahanna, Ohio, purchased his Massivit 3D printer at the end of January and it was up and running by the end of February. He wanted to make a splash at an upcoming trade show, so he 3D printed 7-foot-tall Rock ‘Em Sock ‘Em Robots to garner the attention of show-goers.

“We had five-to-one lead growth from our past experience at the trade show because of the 3D. We walked away with 400 qualified leads,” says Burt. “We have about 50 normally. We did really well.”

Just having the 3D printer has brought in new work. Eclipse Corp. printed out a Throne of Fries for Burger King, modeled after the one in Game of Thrones. If clients want more than one giant 3D model, however, it makes more sense to make one on the 3D printer and then do vacuum forming and cast molding of that model to make the rest.

“We create the original, and from that we make lots of them for a cheaper price,” Burt says. “We do one-offs as well.”

The robots took 40 hours to print on the Massivit 3D printer. They were printed in pieces: arms, legs, head and gut. Once they were put together, he had to sand them by hand and apply chemicals to the plastic to smooth it out. Then more sanding, priming and painting.

“All of that takes time. It is a process, about 80 hours of work,” Burt says. The entire project from start to finish was about 120 hours. “It is not a quick process until you get into your molding. That is how we found we can speed things up. The molded copies only took about 15 minutes each using rotational molding in which a hollow mold is filled with material that then sticks to the walls of the mold as it is rotated, creating a quick model of the original subject. Roto molding creates a smoother subject so once the robot is taken out of the mold, it is ready for paint. For the most part, he uses the technology for retail spaces that need large quantities.

“The 3D world is pretty new, and it is definitely a game changer. One of the things we discovered in getting a Massivit is it is not just 3D images. We call it printing but it is 3D molding, and building whatever you put in there.”

Burt points out that 3D opens up new ways of displaying and showing and doing things in a retail environment.

“It has led us into things we didn’t think we would be tapping into, and it is great,” he says. Like making tables, oversized tools and trade show display items. “My original thought was that it would complement what we already do for retail spaces and ignite that experience even more.”

The biggest problem Burt encountered with 3D printing is that his customers didn’t know what to do with it when they were first shown the technology and their advertising budgets were already set around traditional marketing campaigns.

“Once we get ideas in their heads, now it all starts coming in. From March to July, we didn’t see a lot of work. Since August, we’ve been running nonstop with it. We are getting close to having a backlog, which is a good thing,” Burt says.

Mimaki’s 3D printer is a CMYK output device. It also puts out white and clear. It starts off as a liquid resin and then it is UV cured to a solid.

“It is very inkjet-based technology,” says Hope. “That’s where we’re able to get really photorealistic output from our machine.”

Mimaki’s first customer was actually a signage shop in Las Vegas. The owner was frustrated with having to compete with other sign shops in town. Everyone was competing on price which was driving their margins into the ground, says Hope. They ended up purchasing a 3D printer and are now trying to transition from a 2D print shop to a 3D shop, which offers “more potential to be a little more in control of the market,” he adds.

One of the pros for using Mimaki’s 3D printer for signage is that it can be created as a single piece with full color. When using a CNC to carve wood, for instance, the sign shop would then have to paint it. But in 3D printing, it is an unattended process. You send the file to the machine and the entire thing happens at once. “You don’t have to engage in hand painting or secondary processes,” Hope says.

The 3D printers also don’t make a lot of noise or create a lot of dust like more traditional methods of building 3D signage. And like any new signage technology, as prices come down and the technology becomes more widespread, more people will begin to adopt it, he says.

Sykes says that the Massivit machines can create channel letters and custom-shaped frames for silicon-edge graphics. 3D printing makes printing channel letters a dream because there is no limit to the fonts and geometric shapes they can print and the letters can be printed to curve around other objects. Because everything is printed in translucent white, the letters can be illuminated from within.

Some sign shops are printing molds with Massivit 3D printers for thermoforming projects.

Massivit machines use a proprietary gel to make their 3D objects that are cured as they print. Because of that, “we can create an object of any size you want to by gluing pieces and parts together,” Sykes says.

One of Massivit’s customers had a client in Australia that wanted them to 3D print a Louis Vuitton pop-up store for a shopping center in Sydney. It took two weeks to print and three days to put together. The small shop was 34 feet long, 20 feet wide and 8 feet tall. The structure was covered in self-adhesive silver vinyl. The shop was in the mall for a month before being removed. That job ended up paying for the client’s Massivit 3D 1800 printer.

“Your only limitation is your imagination. With 3D printing, if you can conceive it, you can probably print it,” Sykes says.