Over the past 20-plus years, direct-to-film (DTF) printing technology has continued to advance to the point where it has become one of the most popular ways to decorate fabrics and apparel on demand.

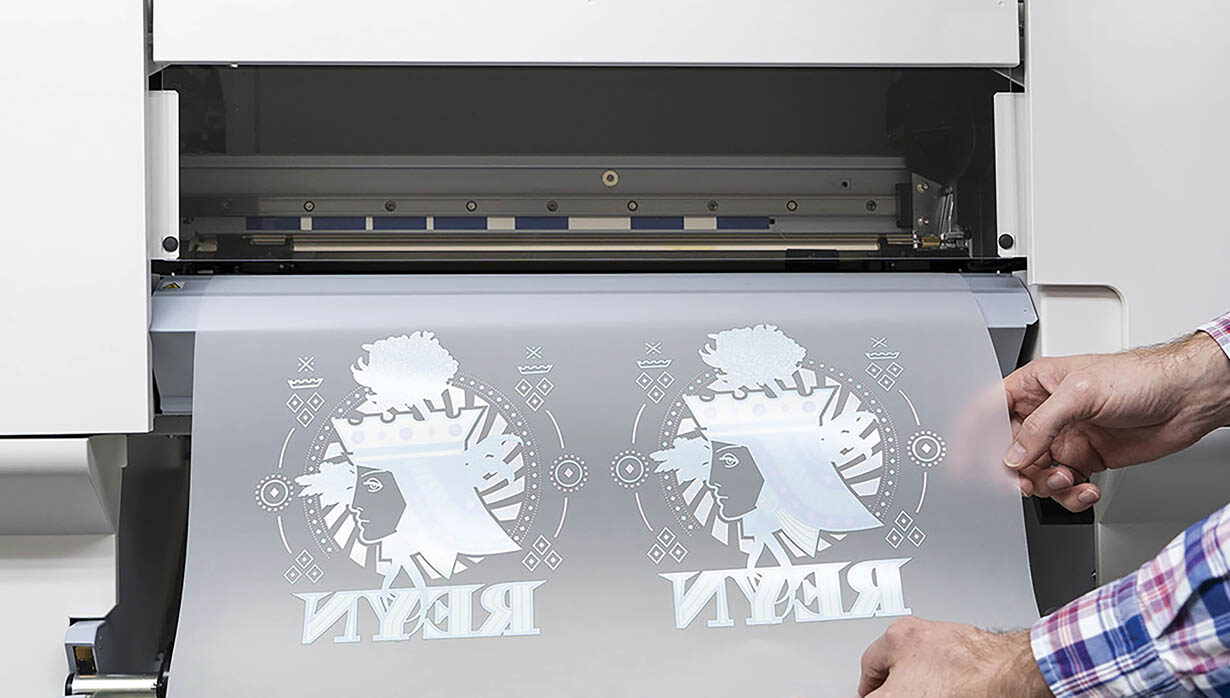

Designs are digitally printed or screen printed onto transfer film. The film is then placed onto a garment, and the design is transferred onto the fabric using a heat press. One advantage of DTF compared to direct-to-garment printing is that DTF can be more cost-effective for larger orders that require colorful and photo-realistic prints.

Films & finishes

“DTF printing primarily uses coated polyethylene terephthalate or PET film, a strong, clear, and flexible plastic film made from polyester,” said Tim Check, senior product manager of professional imaging for Epson America. “The film comes in different finishes, with cold peel, hot peel, and hybrid peel variants being the most popular for DTF film applications. Transfers can be printed ahead of time and stored for later use, offering flexibility for on-demand heat application.”

PET film works well for industrial applications because of its “excellent strength, chemical resistance, and dimensional stability,” he said.

Depending on the application and transfer timeline, there are minor differences between the different film finishes.

Hot peel transfers allow for immediate peeling after it is put through the heat press, which speeds up production cycles. Cold peel transfers require cooling before peeling, which can improve the transfer’s adhesion and durability, especially on textured or thicker fabrics, he said.

Hybrid peels offer a balance, allowing partial cooling for easier handling without compromising quality.

Sergio Ramirez, marketing manager at Supacolor in California, said his company uses all recyclable PET film with a hot peel process.

“It has been fun to see all the things we are developing, paving the way for heat transfers to be a more accepted thing,” he said.

Supacolor decided to use hot peel over cold peel because it wanted to be more efficient in a high-production environment. Most of its customers are screen shops and printers. “When pressing 400 T-shirts, setting them aside and re-pressing them later is not as efficient vs. peeling right there and done,” Ramirez said.

The inks

Supacolor uses water-based inks in CMYK with its own formulation of adhesive that is used on both digitally-printed and screen-printed transfers. Some companies use UV inks to print their transfers.

Ramirez said that water-based inks give transfers washability and longevity. When DTF first started, transfers would last 20 to 50 washes. Now they will last 80 to 100-plus washes.

The company uses both screen printing and digital printing for its hybrid DTF transfers. First, a white ink base is screen printed onto the film. Then, the colors are applied on top of the white using a seven-color digital process. An adhesive is applied to the top and cured.

“Not many people are doing it the way we do,” he said.

The company makes two types of transfers, a traditional transfer and what it calls SupaDTF, which is 100% digital, printed on an inkjet printer. The main difference between the two is that the SupaDTF transfer uses a water-based, seven-color process with Pantone color matching. It is also able to print metallics.

We Must in Toronto offers industrial solutions for DTF transfers, which make up 75% of the company’s business. It uses water-based pigment inks that are “very environmentally friendly and skin friendly,” said Amit Kumar, CEO of We Must. It offers Pantone color matching, which is new to the DTF market. The company is adding a nine-color solution that will further expand its color gamut from 350,000 possible colors to nearly a million, which is “pretty huge in terms of colors that we are able to do,” he added.

The company offers silicone transfers, reflective metallic, DTF embroidered patches, single-color transfers, and digital puffs. Puffs are digitally printed in any number of colors and gradients, he said. The ink puffs up when heat is applied.

“Silicone raised prints are a very trendy thing since big brands are using it,” Kumar said. “They are very popular right now.”

The company’s DTF embroidered patches use a combination of embroidery and DTF printing when clients want the expensive look of an embroidered patch, but their design uses color gradients that are not possible with thread. In this case, the design is printed on the patch with embroidered accents surrounding it.

Special-effect prints offer metallic designs and reflective transfers for workwear or outerwear.

Heat & pressure

Epson’s Check said that “Proper heat (typically 280–320 F or 140–160 C) and medium-to-firm pressure (30–50 PSI) are essential for ensuring a strong adhesive bond between the ink and garment. Time, temperature, and pressure should be carefully calibrated based on the fabric and transfer type to ensure durability and visual quality.”

Supacolor has developed different types of transfers based on the type of garments they will be adhered to. For example, a Nike Dry-FIT polyester jersey with a pattern on it would require a blocker layer so that the fabric’s pattern wouldn’t show through the printed transfer.

Normal DTF transfers are applied at around 300 to 320 F, Ramirez said.

For fabrics that might melt under high heat, the company uses low-cured adhesive heat transfers that allow a shop to press a transfer as low as 260 F, so it won’t burn the garment or leave press marks on it.

“Being able to press something at that low temperature cuts out the guesswork if someone is working with an injurious item, for instance,” Ramirez said.

The company also offers headwear heat transfers that can bridge the seams on a baseball cap. The transfers are printed the same way as other hybrid products, but the difference is in the adhesive formulation the company uses.

“It won’t stretch out or be warped. It looks more natural, like it is part of the hat. It is not like looking at a sticker,” he added.

Kumar says We Must’s regular DTF transfers work on any fabric, from cotton and polyesters to blends. These transfers work best when applied at 290 F. The company’s DTF Cool transfers were developed for more technical fabrics, such as rayon and nylon, that have polyester coatings that can prevent regular DTF transfers from adhering properly.

DTF Cool has a stronger adhesive and is applied at 250 to 270 F to avoid scorching. The company also sells silicone sheets that can be placed on top of the material when pressing, which also help prevent scorching.

When transferring onto dye-sublimated fabrics, the company uses a DTF dye blocker that prevents the fabric’s color from bleeding through to the transfer design.

Common transfer issues

Common transfer issues include poor adhesion, ink bleeding or smudging, cracking or lifting, or powder inconsistencies, said Epson’s Check.

Poor adhesion is “often due to incorrect heat or pressure settings,” he said. Ink bleeding or smudging may result from over-inked film or insufficient drying. Cracking or lifting is usually caused by improper curing or incompatible fabric, and uneven adhesive powder coverage can lead to patchy transfers, he added. “In addition, aged powder can absorb moisture and clump, resulting in uneven coverage.”

Check added that “Following the film and powder manufacturer’s recommended specifications, and regularly maintaining your print and press equipment, can help minimize many common transfer issues.”

Supacolor’s hybrid process requires a lot of maintenance, Ramirez said. “You always want to make sure you are keeping it as clean as possible. The more surgical you can keep the printer, the better it will perform in the long run.”

Printheads must be kept wet and never allowed to dry out. Clogged printheads can cause major headaches and cost money. “If you invest in a DTF printer, or any equipment for that matter, try treating it as if it were an immaculate show car,” he said, “keep it looking good so it will perform in the way you need it to. Make sure you are always maintaining it.”