When a back injury forced Canadian mechanic Chris Moulds to consider a career change, he leveraged a graphic design certification into a unique screen-printing business. In 2018 he founded his company, AshCo Design, and got his start by selling vinyl and wood signs featuring inspirational sayings amid the “Live, Laugh, Love” trend. As the business grew, Moulds purchased a four-color, two-station manual screen-printing press to ramp up his sign production and also allow him to experiment with screen printing apparel.

“That press never really registered, and it almost defeated me from the start,” Moulds said. He used his mechanical background to weld steel piping onto the frame so it wouldn’t flex and bend so much.

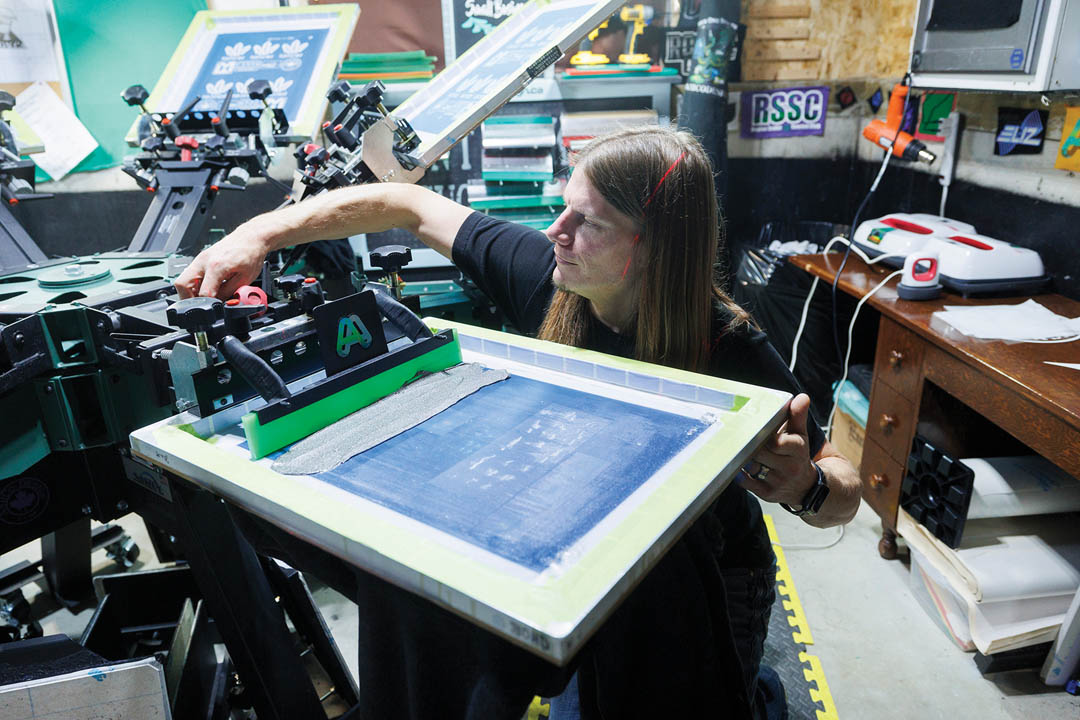

Not to be deterred, Moulds purchased a Vastex V-2000HD six-color/six-station press from Canadian distributor Discovery Lancer. On the new press, he taught himself screen printing by watching YouTube videos and joining social media user groups.

Once he had a handle on screen printing and expanded his business offerings to include more apparel, Moulds saved enough to purchase a LittleRed X2-30 infrared conveyor dryer, also from Vastex. With production stepped up even further, Moulds was determined to develop his skills beyond standard screen printing. He began working with high-density and lifted prints. Initially, he worked with heat-transfer vinyl that was about 600 microns thick, he said, meaning .02, or 1/40th of an inch.

“After about six months of repeated washings, the viny would start cracking, so I knew I had to find another way.”

High-density prints

Ever the DIYer, Moulds continued to tinker with pressing stacks of ink for high-density prints. His technique, he later explained to Vastex, goes like this: To prep the press for high-density prints, he lowers the print heads by turning the off-contact knobs as far as they will go. Once the screens are registered on press, he fine-tunes the micro registration and turns the off-contact knobs to gradually raise the screens as he builds his high-density layers. Some of his highest stacks have consisted of as many as 12 layers — and he still has room to raise his screens higher.

In addition to tight registration, he explained, precise vertical travel of the press’s off-contact adjustment is critical for the vertical build-up of high-density layers in alignment with crisp, clean edges. This ensures that the printhead and screen remain parallel to — and vertically aligned with — the pallet, from the lowest to the highest off-contact setting.

Anti-backlash knobs enable Moulds to accurately predetermine the degree of knob rotation — and corresponding off-contact adjustment — required to prevent the ink from mashing the previous layer when applied.

“Being able to lift the print heads as I’m printing has helped tremendously, because it gives me a lot of room to stack prints,” he told Vastex, adding, “Micro registration ensures that the high-density ink doesn’t run down the side of an existing high-density layer or squirt out — similar to what happens when you put too much peanut butter and jelly on a sandwich and push the bread together. When this happens, the ink puckers and creates stiff peaks, which makes your print look unattractive.”

The process is time-consuming and requires patience; he has spent up to six hours working on one shirt with printed stacks that are 1,800 microns (.071“) thick.

One of Moulds’ most ambitious projects, and one that caught the attention of media, is a series of hoodies for his children featuring a 9“ X 7“ high-density Lego base plate.

Essentially, Moulds made wearable Legos. From the base plates now firmly attached to the fabric, his children could add Legos to their hoodies. Moulds said they built a house out of the bricks and attached it to the shirt.

“My son ran around while he was wearing it. When people saw it on social media, my inbox blew up overnight.”

The process

Quality high-density prints begin with a smooth, flat base layer, Moulds said. Irregularities in the base cause peaks in the ink, which show up through the high-density stacks. Moulds uses a handheld heat press to cure the ink while the shirt is on the press. The rubber pallets on the V-2000 press help facilitate this process.

After curing the base layer, he cures subsequent layers on a press using a flash dryer between stations. He then runs finished shirts through the LittleRed X2 dryer that has a 30“ X 66“ long conveyor belt. For standard prints, Moulds raises the heater hight 2.5“ and, for high-density prints, he raises it 4“ to 5“ to prevent ink from boiling and forming bubbles on the print surface. He raises the temperature from a usual 515 F to 600 F for shirts and hoodies, then runs it through the dryer two or three times if the ink is particularly thick.

Looking ahead

Specialty products now make up half of the work that Moulds does at AshCo Design. Aside from high-density printing, he also fulfills orders for glow-in-the-dark, puff ink, metallic, and other nontraditional screen printing products. For high-density printing, he averages around 100 pieces in an average workday while also running his shop. Among his biggest high-density orders was 160 tone-on-tone hoodies for a regional park. The hoodies were printed with six layers of high-density ink measuring nearly a quarter inch in height that took four days to print.

Moulds said the projects themselves speak well to the pricing of jobs to account for his extra work. He often prices orders based on the thickness or build of ink.

“If they want a certain micron in height, I will entertain that. A lot of my high-density work is left in my hands from the client. My work speaks for itself, so most of them trust me to make something truly amazing for them. The additional costs are pretty much self-explanatory once I start telling them about the process involved.

While he hasn’t yet trained anyone to help with high-density work in his own shop, Moulds has served as a reference to help others figure out the process for their own work. As he has become the go-to in his region for these products, he said the workflow has improved as he has learned to be more efficient. “I just had to rearrange the shop slightly because I crafted some handmade jigs and tools the make the process flow a little smother.”

Moulds is interested in adding an automatic press to see how far he can take high-density printing. The more people who hear about his work, he said, the more orders he receives. His work continually garners attention when he wears it in public.

“It never fails. People walk up to me all the time and say ‘That’s the coolest shirt I’ve ever seen. How do you do that?’”