Direct-to-film (DTF) printing — a process that transfers digital prints onto apparel using a heat press — is transforming the apparel decorating industry due to the major benefits it provides to print shops and their customers. The fairly new process allows for faster turnaround times, versatile applications and substrates for various industries, multiple and diverse garment placements, no minimum order quantities, high-quality prints with high color counts, streamlined production, and a low barrier to entry.

Incorporating DTF printing into your production process can feel like a daunting task, whether you’re a new business owner or a veteran screen printer. However, offering DTF printing doesn’t mean you have to purchase new equipment and learn an entirely new technology. Read on for the three ways that you can integrate DTF printing into your apparel decorating business today.

Bring everything in-house

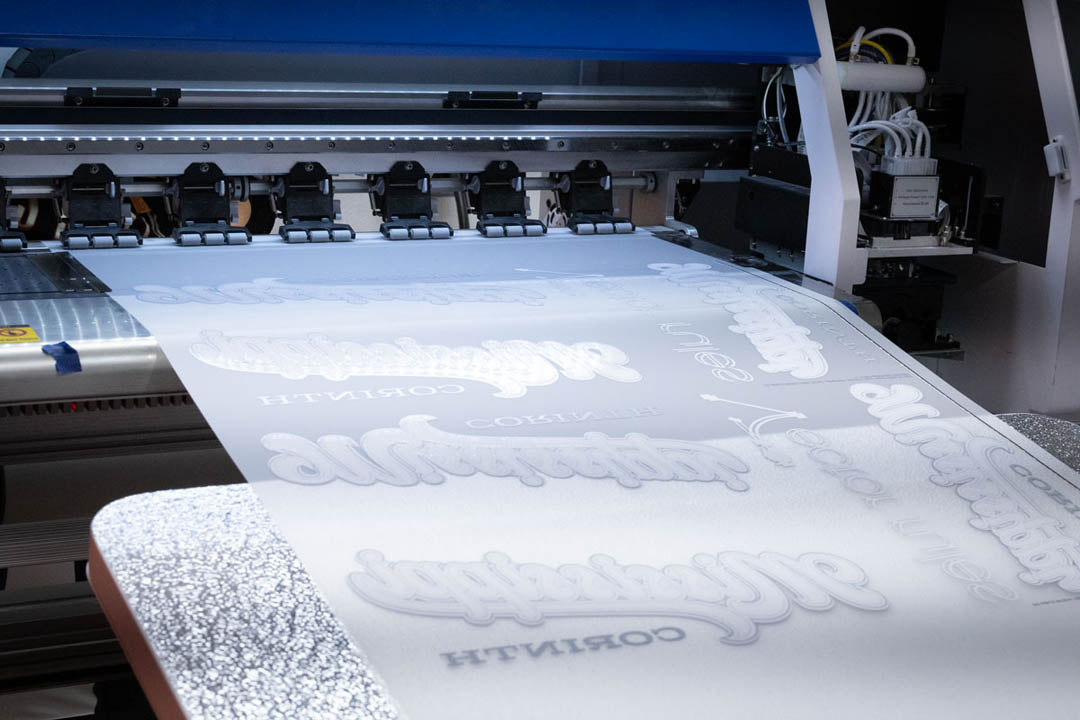

One way to offer DTF printing is by purchasing equipment and consumables. You will need a DTF printer to print your design onto a heat transfer film. DTF printers use water-based inks in magenta, cyan, yellow, and black to create a wide range of different colors, and also require white ink.

One way to offer DTF printing is by purchasing equipment and consumables. You will need a DTF printer to print your design onto a heat transfer film. DTF printers use water-based inks in magenta, cyan, yellow, and black to create a wide range of different colors, and also require white ink.

Once the design has been printed onto the film, it’s treated with an adhesive powder and cured. This can be automated or done by hand. You then apply the film directly to where you would like the design on the garment and use a heat press to transfer the graphic to the fabric.

Krystin Leary, owner and operator of Origin Apparel Screen Printing in Steamboat Springs, Colorado, recently brought DTF in-house. Along with manual screen printing, the shop was purchasing DTF transfers and then heat pressing onsite. To speed up production and get orders to clients in a faster time frame, they now operate an Arcus DTF printer after making a connection with Axiom America at an industry event. “It was a no-brainer,” said Leary. “The benefits include client convenience, basic education, and satisfaction, as well as the best possible decorated product.”

Before deciding if this is the right option for your business, you need to consider your environment and workflow, the quality of equipment and products you purchase, staff training, support from your vendor, continuous education, and overall cost.

Editor’s Note: To learn more about what to consider when bringing DTF in-house, read page 31 of the January 2024 issue of GRAPHICS PRO magazine

Outsource DTF transfers & heat press in-house

In this case, you don’t need to invest in a printer, but you do need to purchase a heat press and find a reliable source for your DTF transfers. When vetting a potential printing partner, communicate with other print shops for referrals and testimonials. (Pro tip: Find someone local. Remember, this is your partner, not your competitor.) Once you’ve connected with a few different vendors, request multiple samples, test the transfers on various substrates, and consider the turnaround time from ordering, receiving, heat pressing, and shipping to your customer.

When you find the best partner for your business, you will submit your ready-to-print gang sheet file (some vendors offer an online builder to create your own). Prints are sold typically at a price per square foot. You should expect to receive your roll of printed transfers within one to three business days. Then you can cut and apply your transfers onto your substrates with a heat press and ship the finished product to your customer.

One of the benefits of outsourcing transfers for Family Industries in Los Angeles is streamlining. While the company spends at least $1 million in transfers per year from Supacolor, they have no plans to bring DTF in-house. “Because a lot of what we do is customer service, bringing in a machine for us would mean shifting some of that time or hiring more staff to accommodate that,” said Adam Calvary, director of Events & Special Projects. Purchasing transfers is still cost-effective for the print shop, and most importantly, Calvary and his team can trust the quality of prints because they have a strong relationship with their vendor.

Outsource everything

If you have no interest in purchasing any form of DTF printing equipment, you can outsource the entire process to another shop through contract printing. This means you will offer DTF printing as a service, but never touch the finished product. For this to be successful, you need to have a trusted partnership with a verified business (see above) and have made a significant investment in e-commerce and automation. Reasons to do this may include job quantity, environment and size of shop, speed of delivery, and cost. Once your customer has completed an order, you will send the artwork and blank substrates to the print shop. They will print the job and dropship the printed apparel to your client.

For the last three years, Ronda Lee Guill at Midtown Printing and Design in Mineral, Virginia, has worked with Limitless Branding in Front Royal, Virginia, for the shop’s embroidery, screen printing, and now DTF transfer needs.

“When Limitless Transfers started printing DTF transfers, Spencer Chernoff [founder & CEO] spent the time to educate me on his product and how to apply and press myself. He worked with me until I had it perfected,” said Guill. “My business grew extremely fast and the orders increased as my reputation for delivering a great, full-color product became known. I had two orders in one week that totaled more than 400 shirts. I couldn’t get that completed on my own.”

Limitless Transfers was able to take on the job and meet the client’s deadline. “They were perfect! Our client was very happy. Now, Spencer does all our orders,” she continued. Outsourcing DTF transfers allows Guill and her team at Midtown to focus more on sales and keep their business growing.

Offering DTF printing in some capacity, whether you bring everything in-house, outsource transfers, or outsource the entire process, gives you the opportunity to continue saying “yes” to your customers.