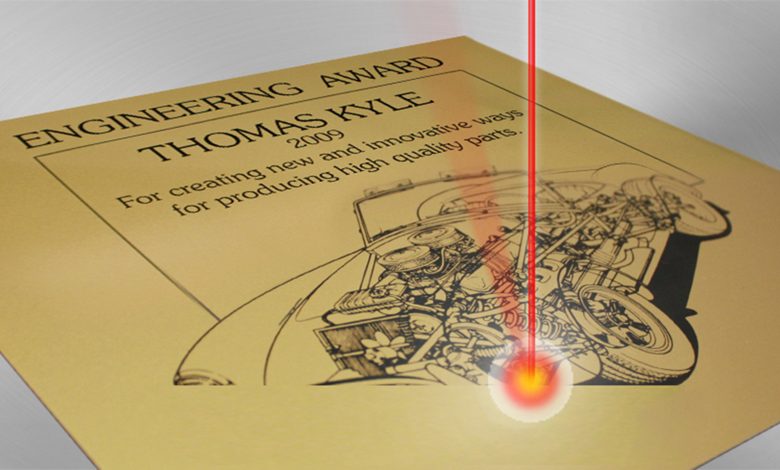

2 Ways to Avoid Metal-Marking Problems

Keep these pointers in mind

1. Ensure the metal is perfectly flat in the laser. Some metals are marked in an ablative process to remove the lacquer or other coating, while others create a bonding or thermal conversion where focus is key.

2. Traditionally, if the mark doesn’t look good, give it more power for the laser to cut deeper. In the case of metal, giving too much power seems to be quite common. Metal is a great heatsink, so it doesn’t take too much power to mark the surface. Applying too much power can cause the metal to warp, the marking to balloon larger than it should, and/or discolor the marked area.