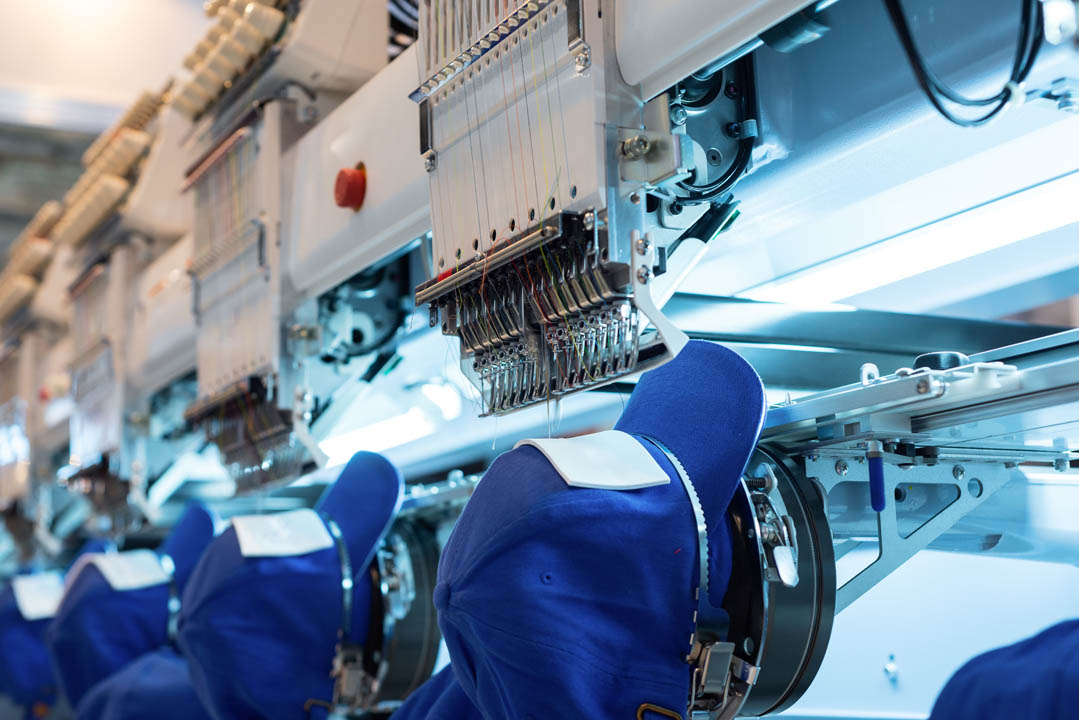

Let’s walk through a full breakdown of how to know when, and if, you are ready to expand your embroidery business by adding more equipment. Once you make the decision to add equipment, there are key concerns to consider as you choose what to add. And then, just to be on safe side, there are signs to watch for that might mean you should wait just a bit longer before expanding.

-

Photos courtesy of Jennifer Cox Sales volume: Are you running behind on your orders often? Do you think you can run your equipment more efficiently to get more production, or do you think you are operating at your full capacity? If you are turning away orders or working overly long hours to keep up, it may be time to grow. If you have slow periods or seasonal dips, it may be in your best interest to stabilize your sales volume before you add equipment.

- Deadlines: Do you have a growing list of orders that are running past their deadlines, assuming you are setting reasonable deadlines? This can be a signal that you are maxed out with the equipment you have.

- Repeat customers: Do you have consistently returning customers? If a percentage of your business is predictable, this steady income from repeat business is a good indicator of your long-term success. It may be a good time to invest in more equipment.

- Pricing strategy: Are you making a decent profit with your pricing strategy? If you are confident in your pricing and profits, determining how much of a machine payment you can afford is pretty straightforward. If you do not know your numbers (profit levels in particular) and believe that adding equipment is going to increase your profits, you would be much better served by developing a thorough understanding of your financials before considering adding a machine payment. Otherwise, if you are in a financial hole, you could be digging it deeper rather than filling it in!

- Budget & cash flow: Do you have funds set aside for business growth, or access to affordable financing? Draining your savings or emergency funds may not be the best use of that money. If you have more month left at the end of every month than you have money, that indicates that you are stretching every dollar or relying on debt to cover essentials. An equipment purchase could put your business at risk.

- Space: Do you have space available, or can you carve out the space so that you can add equipment without it crowding so much that it creates inefficiencies? Cramming another machine into an already tight space can create more frustration than additional production capacity.

Production: Do you have the time to operate and maintain additional equipment? While adding a machine does not double the time to run jobs, it does increase the pace and the workflow. If your equipment is actually sewing less than 25% of the hours you work, adding equipment may overwhelm you. Highly efficient operations run their equipment 50%-60% of every working hour. If you are already feeling overwhelmed running the equipment you have now, adding a machine will not solve the core issue.

Production: Do you have the time to operate and maintain additional equipment? While adding a machine does not double the time to run jobs, it does increase the pace and the workflow. If your equipment is actually sewing less than 25% of the hours you work, adding equipment may overwhelm you. Highly efficient operations run their equipment 50%-60% of every working hour. If you are already feeling overwhelmed running the equipment you have now, adding a machine will not solve the core issue.- Labor: Are you confident in your ability to operate multiple machines — or do you have someone who can help? If you are a home-based business, will you want to add staff who will then be working in your home? If you are in a retail location, do you have access to people who want to work?

- Marketing: Do you have a marketing plan that brings in new opportunities consistently? If you never know where the next orders are coming from, and are not doing anything to bring them in, it may not be time to add equipment, as that machine could just sit there expensive and idle.

- Expanding product mix: Are you adding equipment to increase your product mix, such as adding a machine that can embroider finished caps, or has a larger sewing field? If you have customers wanting these options, adding the right equipment will increase your sales rapidly. If you do not have a clear business plan or niche, more equipment could lead to overwhelm instead of growth.

- Workflow & information management: Do you have systems in place to keep orders organized? If a customer says, “Just do it again,” is that a nightmare for you? Or, is it no big deal because you can access all the necessary details easily? When you scale your business by adding equipment, having systems in place to keep the workflow smooth is essential.

- Business vision: Does scaling your business now align with your business goals, and your personal goals? Growth is hard, and it will have an impact on your entire life. Make sure you are ready to evolve without paying too high a price, such as your mental health, your sleep, and your relationships.

Once you decide that you are ready to add equipment, the next step is to determine what equipment to add. Here are key factors as you consider your options:

- Production needs: Do you need speed, size, or specific capabilities, such as a commercial machine, a cap system, or a larger sewing field? Match your equipment selection to the jobs and customers you want to say “yes” to.

- Budget: How much of a payment can you afford and what are the hidden costs, such as maintenance, parts, hoops, new software, and thread.

- Consistency: If you like the equipment you have, and if they offer machines that will meet your needs, that may be the way to go as the hoops may be interchangeable, the software will be the same so that you can avoid a learning curve, and the support will be the same. On the other hand, if you are not really sold on what you have currently, you might as well look at all the available options.

- Brand reputation: Look for brands with a good reputation in the industry. There are user groups for just about every brand of machine online, and there are online communities for embroidery and apparel decoration business owners. These folks are more than happy to tell you if they love their equipment or not. Buying a machine is the beginning of a long-term relationship. Make sure you pick a company that resonates with

you and is not just offering the cheapest deal. - New or used: If you are buying equipment from a brand that you already own, a used machine may be a good option for you. Be sure to do your due diligence so that you know exactly what you are buying. Consider having your own service technician service and evaluate the machine before you finalize the purchase. If you are buying a brand that is new to you, getting a new machine establishes a relationship with that company so that you have access to their training, support, warranty, and other customer benefits.

- Parts, service & tech support: Does the company have a good parts supply, tech support or training available online, as well as service techs that will maintain the equipment, or teach you how to do maintenance? Better and faster support keeps your downtime to a minimum.

- Software & updates: Does the machine come with embroidery design software? Is it software you already know and use? It is upgradeable, is there training available for it, will it operate all your equipment, or only the newest one?

- Resale or upgrade options: If your business continues to grow, can you sell or trade up the machine to help finance new equipment?

How many needles? One of the questions I hear the most frequently is, “How many needles?” Here is the thing — most company logos have less than six colors in them, so even basic multi-needle machines have enough needles to run the majority of your customers’ designs without changing out threads. If you plan to create embroidery designs that are more intricate such as animals, florals, and scenes, then a multi-needle machine with as many needles as possible may be more beneficial.

No matter what you decide, keep on keeping on, as the saying goes. You are thinking strategically about your business and making sure that you are running it to the best of your ability. Whether you are hitting your stride and going into a growth phase or staying on track with what you have now, it is an exciting time to be an embroidery and apparel decoration entrepreneur!

Production:

Production: