11 Ways to Master Your Embroidery Machine Right Now

A good plan includes both machine-specific tasks as well as tweaking the work and production areas near your machines

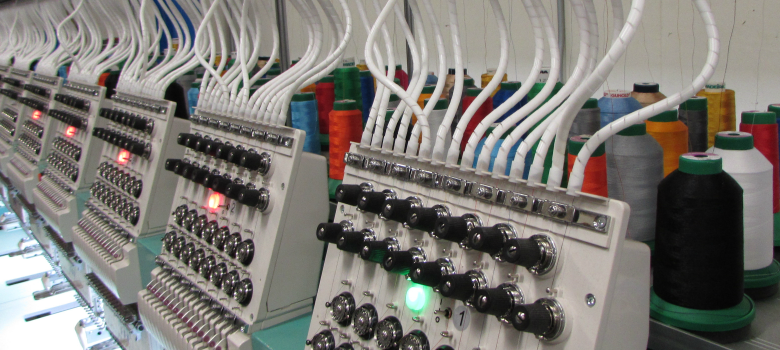

Decorators are always on the hunt for ways to keep their embroidery machines running smooth, so production is as quick and efficient as possible. A good plan includes both machine-specific tasks as well as tweaking the work and production areas near your machines.

Here are 11 ways to make sure your embroidery machine(s) and production area perform at their best for you, every single day.

1. Get organized pronto. The more organized your work area is, the more time and steps you’ll save. For example, keep the tools you use most frequently in your production area or nearby. You can also store your threads by color and type, with clear labels, and keep your thread close to your machines. Consider creating several stations, if needed.

2. Stay clean. This should go without saying, but try to keep your work and production areas as clean and ordered as you can at all times. While this can be difficult when you’re flying through embroidery orders, it’s necessary to stay organized to stay moving at that pace. Ask your employees to keep tools where they belong and put them back when they’re done. Also, keep everything dust and lint free. If your threads get too dusty, they may be more prone to breaks.

3. Say goodbye to dust. Before you start daily work, blow out your embroidery machine’s rotary hook and knife areas. You may also want to add oil on your hook and rail. This can help eliminate thread breaks. You should do this every day or after every eight hours of sewing time.

4. Baby your machines consistently. Pick one day a week, preferably Friday or Saturday, for your maintenance. Start production earlier that day so you can fit it in.

5. Don’t forget to oil. Your machine manufacturer should provide you with a list of parts you need to oil and how often. To keep your machines running happily, stay on top of the recommended oiling schedule.

6. Keep thread and needles close. For each design, place the thread colors you’re going to use in a design on the closest needles for each color. For example, if you have a six-color design, they should correspond with needles one, two, three, and so on. This speeds up your color change time. Try to program designs with the same or similar colors in the same order to save time and effort.

7. Purchase pre-cut backing. Buy backing in the sizes you use most frequently and store them close to your hooping area. If you don’t want to buy pre-cut to save some money, cut them in advance to save on production time.

8. Keep an eye on your needles. If any of your needles have rough spots, you’re going to experience thread breaks. It’s important to keep track of your needle changes with an ordered log sheet. As performance wanes for a particular needle, replace it and then log it, including the date, size, and needle type. You can use a different login sheet for each machine or head and store them in a binder.

9. Take a good look at your digitizing. Sometimes, it’s not the machine. A poorly punched design can result in thread breaks and slower production. Additionally, stitches placed too close to each other can also cause thread breaks. Too many trims can also slow things way down.

10. Spend time with your machine. Really getting to know your device and its features can save you a lot of production time. This includes cleaning needs, maintenance must-haves, and troubleshooting tips. Read your machine’s manual so you’re prepared when you experience downtime during your busiest day. That way, you can minimize the time you’re not stitching and stay on schedule.

11. Tame your tensions. If you feel like your tension is off, do a quick tension test by sewing a line of satin stitches in each color, and adjust as needed after you’ve compared the tensions.

When you keep your embroidery machines and work area in tip-top shape, you’ll see rises in your production time and efforts, which is what we all want, right?

More on the topic of embroidery:

Ready to Up Your Embroidery Game?

The Role of Art in Embroidery: Painting with Thread