You’ve got your fiber laser paid for, and you’re waiting for it to be delivered. Let’s talk a little about fiber laser safety, and what you need to know before ramping up your equipment.

Eyes

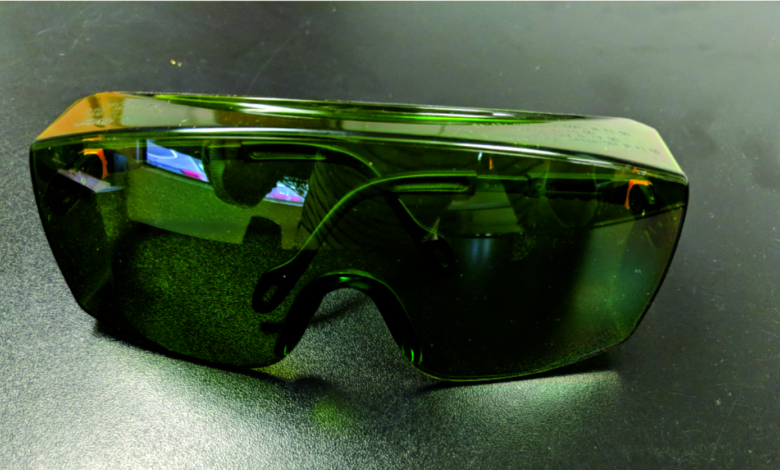

A fiber laser that has an open bed system needs a little more thought put into safety. I am used to my CO2 lasers and their safety needs, one of which is eyeglasses to prevent the reflected beam from hurting my vision. With the CO2 lasers, a simple pair of protection glasses is a perfect and easy fix. I did not realize when looking into my fiber laser that the different wavelengths also carried different requirements for eye safety.

Luckily, the folks over at Radian Laser Systems let me know I needed specialty glasses that were made to stop my specific fiber laser’s wavelength. I highly recommend buying the safety glasses from your laser supplier and not trying to shop around to save a few bucks. If the ones you buy online elsewhere are not properly rated for the laser you are running, you put your eye safety as well as your customers’ and employees’ eye safety at risk. I have several pairs of safety glasses available at all times.

Lungs

Don’t even play around with this one. When we use fiber lasers, we vaporize materials. When a material is vaporized, it poses a whole new set of risks that need to be addressed properly. In our field, we cannot simply put on a dust mask and assume that we are safe. A dust mask only stops the dust—you still breath in the dangerous chemicals released from the laser cutting and engraving process.

I urge everyone to become familiar with what you put into your machine and how the laser affects that material as well as the chemicals within the material. Always ask for the material’s MSDS sheet, carefully read through it, and check to see what happens when the material is heated and what chemicals are released. Hopefully everyone knows what PVC is by now. When lasered, PVC heats up and releases a vapor that contains chlorine gas. The chlorine gas released is not only dangerous to you, but it is also corrosive, damages your machine, and voids your warranty. I have seen folks post about making custom holsters from Kydex and that they are engraved and cut on a laser. As a warning, Kydex also contains PVC (again, check the MSDS sheet) and is dangerous to process.

When I purchased my laser, I was relieved that Radian also sells fume extractors that are made to combat the nasty gases released when processing materials. I ended up purchasing the larger model PA-500fs-IQ unit. This has a three-stage filter system, with the last stage being activated carbon to remove the dangerous fumes. The first two stages are mostly there to remove dust and debris, which helps to prolong the carbon filter life by not allowing it to clog. I highly recommend changing your first filter consistently. The other filters are not exactly low-cost items, and the first filter is relatively cheap to maintain. If your other filters need replacing, do not delay.

When running your fume extractor, I learned that having it on too high of a setting actually shortens your filters’ lifespan. I recommend testing your suction and setting it to the lowest power setting that still captures all the fumes. When set too high, I noticed that my filters were being clogged by large debris and needed changing more frequently.

Skin

Another safety area to consider is exposed skin. If a beam reflects, you want as little skin exposed as possible. I have found that a set of gloves comes in handy when pulling parts out of the fiber laser. They tend to get hot. Again, safety is not an area to try to save money or time on—shortcuts will cost you in the future.