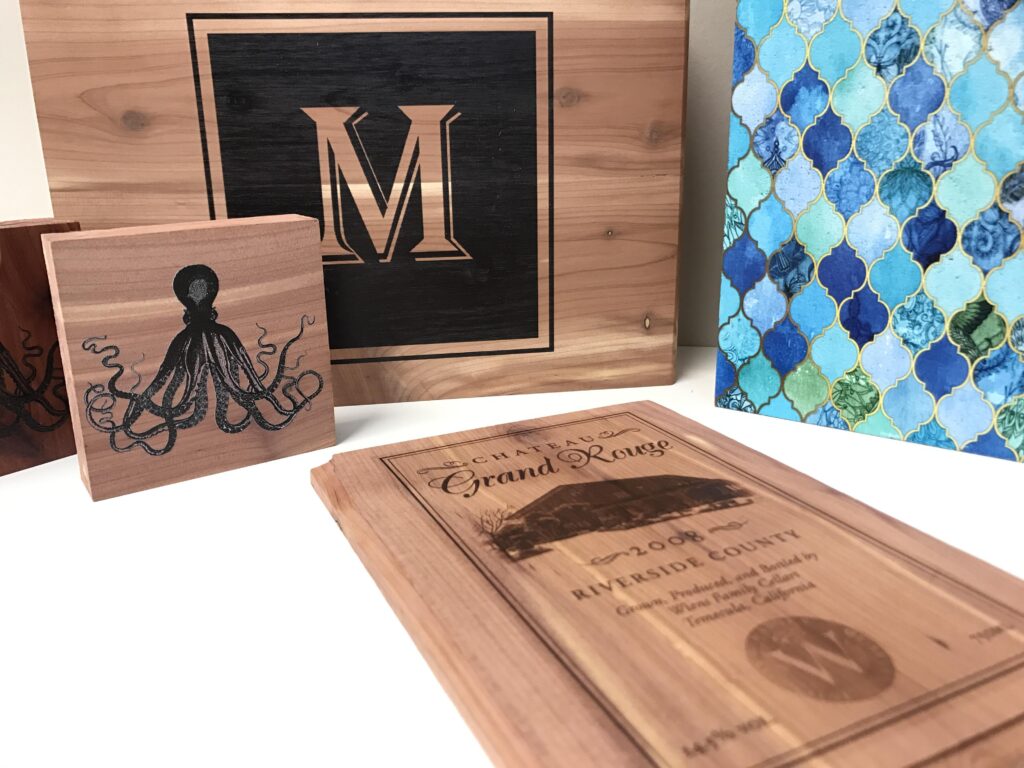

More industries are expanding their product offerings to include wooden substrates. The most common applications for customizing wood include laser cutting and engraving, hand painting, vinyl decals, or a combination of these techniques. Enter UV printing — a quick, cost-effective solution that allows customers to create high-resolution prints on a variety of wooden products.

Coated vs non-coated

Birch, oak, maple, cedar, walnut, bamboo, plywood — there are so many options available on the market that have different color tones and grain density. How will it look when printed? Our print production team has experience in all sorts of wood applications and has developed tips and tricks to ensure images appear sharp.

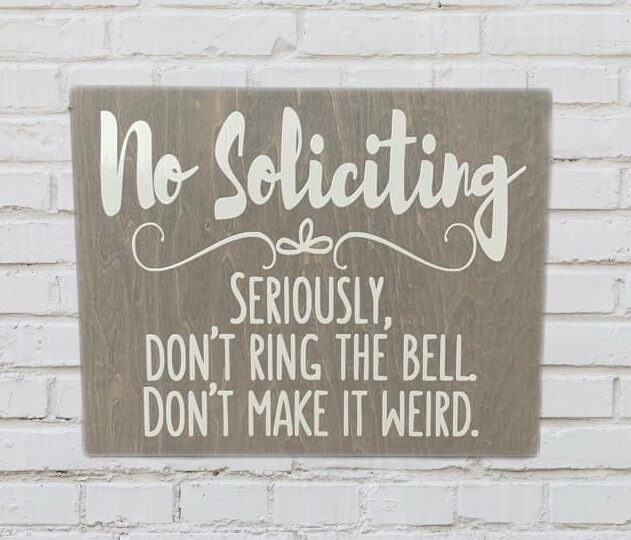

Coated wood is a great surface for printing because it clogs the wood grain and provides a great color surface from the start. In some cases, like home decor signage, it’s more cost effective to quickly paint the base color including the sides. Coatings can be applied using a lacquer, paint (hand-painted or sprayed), stained, laminated, or even UV printed with a white digital ink.

If you are printing onto a raw wood surface using UV digital inks and find the colors bleeding into the wood grain, try printing a layer of clear gloss first in order to clog the pores in the wood. This now provides a smooth, consistent surface for printing and allows you to keep the rustic look without sacrificing print quality.

Laser engraving

Printing UV ink on wood and then laser cutting will not damage the ink on the wood. It may, however, take some precision to line things up — so most users opt for cutting then printing to get good coverage on the edges. You can also combine laser techniques to add both texture and color to your wooden products.

Techniques

Using some Photoshop skills, printing the colored “laser” tone as a graphic adds an interesting technique on wood, especially for those who do not own lasers.

Some materials are too thin or sensitive for laser engraving. When they are lasered, it causes the material to curl and the lasered area to burn. UV printing is a good alternative to obtain the look you want to achieve. One example is wooden invitation sheets. You can Photoshop the design and print the text with a brown tone to look like it has been lasered.

Industries

There is hardly an industry that can’t feature a wooden product in their offerings.

Weddings

The wedding decor industry has used wood in several creative ways with the most popular item being wooden signs. Wedding days are some of the most personal and memorable of someone’s life, and with advancements in photography and the shareability of social media, customized and personal items will be remembered far after the event. A customized sign, a wooden frame, or even a bridal portrait printed on a beautiful piece of wood may appeal to the bride who wants that extra special touch.

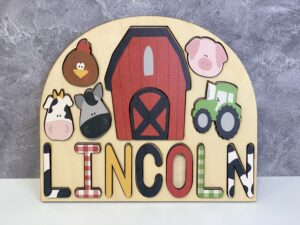

Toys and games

Some of the most gorgeous, timeless children’s items are made from wood. Puzzles, stools, photos, and other games can become a cherished memento with a beautiful image. Using UV printing, you can count on the print to stand the test of time.

Home decor

The rustic appeal of wooden products makes them a popular choice in home decor. UV printing opens an entirely new way to customize wood items for the home. Door hangers, picture frames, coasters, wine racks, and even photos directly printed on wood are all items that can make a house into a home.