Most people think that a compressor is a compressor, but that’s far from true. There are at least five different types of compressors available, and knowing about these is important if you’re offering sandcarving in your shop. The types are diaphragm, piston, rotary vane, rotary screw, and coil.

Diaphragm

Diaphragm, more commonly known as oil-less compressors, are to be avoided for our type of work. For the most part, they are small and do not put out enough air. The larger ones are considered light-duty compressors and are noisy. Many of the known hardware stores carry these types of compressors as their low-end “handyman” compressors. We have used an oil-less compressor a few times only to find that the motors do not hold up for our application. After burning up two motors, we decided to never use one of these compressors again.

Piston

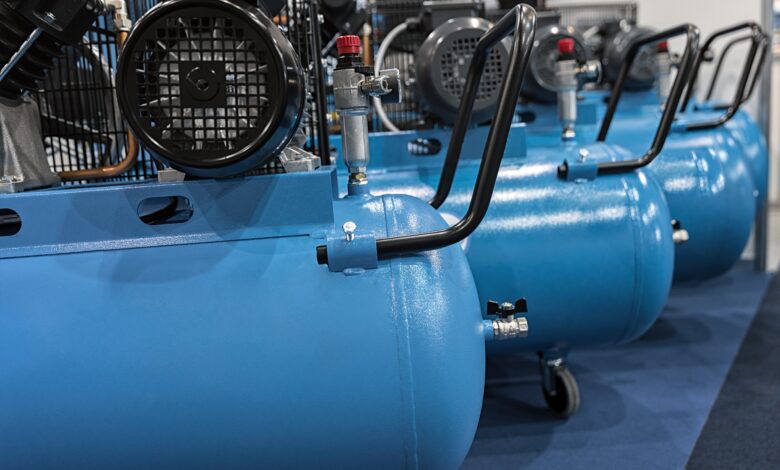

piston and pump found on electric air compressors. (Image courtesy Ruth Dobbins)

Piston compressors are by far the most common type of compressors available today. Their cost is relatively reasonable, their maintenance cost is acceptable, and they are available in many different sizes and come in about three different quality levels: handyman, commercial and industrial. They require an air receiver, or air storage tank, and are available in various configurations from vertical, horizontal, portable, and stationary.

Rotary (vane and screw)

Rotary vane and rotary screw compressors are more high-tech and geared to large air production while also carrying a higher price tag. These types of compressors are made for demanding industrial applications that may require them to run 24/7 and sport a long service life. They generally cost two to four times as much as piston compressors that produce an equivalent amount of air, which mostly puts them out of consideration for glass etchers.

However, if you are a production studio blasting on a continuous basis, one of these compressors may just be what you want. You could blast for extended periods of time with consistent airflow and on top of that get a compressor that produces little noise. We used rotary vane compressors in England for our workshops there and were impressed by their quietness. You could hardly hear them running.

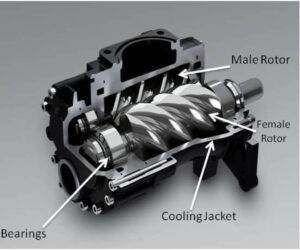

We also used rotary screw compressors in other European countries and here in the U.S. We were impressed with their performance as well, even though they were a bit louder than the vane models. These compressors use a set of twin screws, a male and a female, to compress the air instead of pistons.

Coil

I do not have much information about coil compressors, which are lesser-known to us, since we have not had the experience of working with one of them, but from what we have read, they also seem to be high-quality machines and priced right along with the rotary screw compressors.