If you’re in the laser engraving business, you’ll know that customers often request text or graphics on stainless steel. In the end, what catches their eye is the darkness of the engraving or the high-contrast black marking on the stainless steel. The more pronounced effects the marking produces, the more satisfied the customer becomes.

These effects may look simple enough, but there are some challenges to the process. These top tips will show you how to produce the black marking that customers are after. An S290LS fiber laser engraver was used for this article.

The out-of-focus laser engraving process

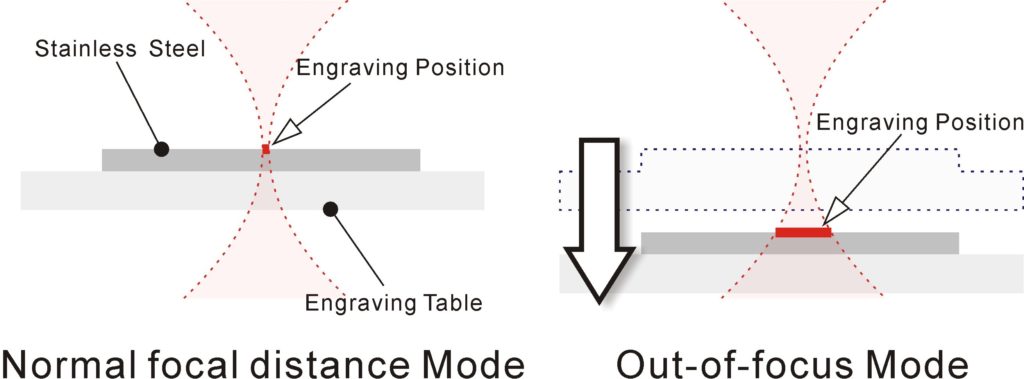

The focus distance is a crucial part of laser engraving. Before we fire up the laser, it is necessary to determine the exact distance between the laser and material to obtain the best processing quality.

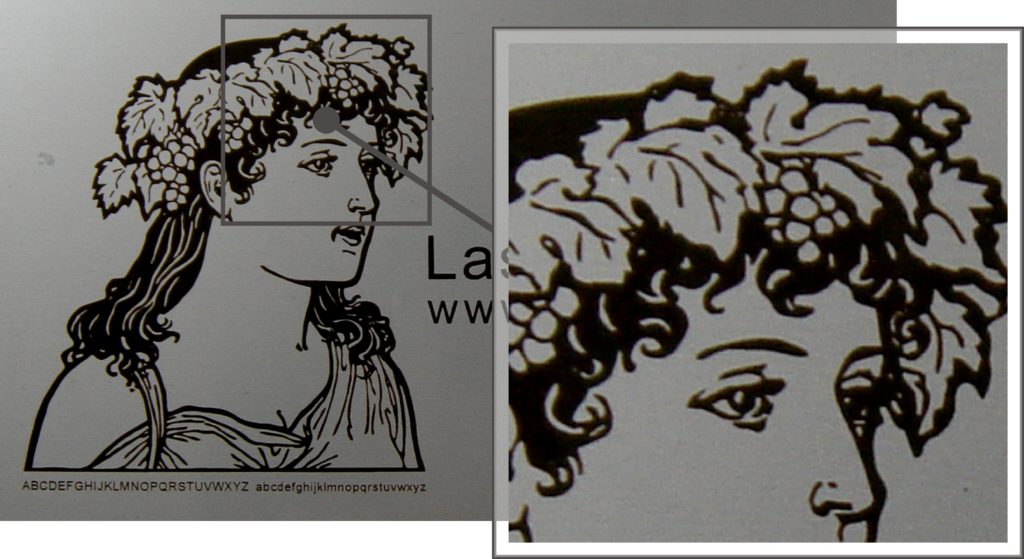

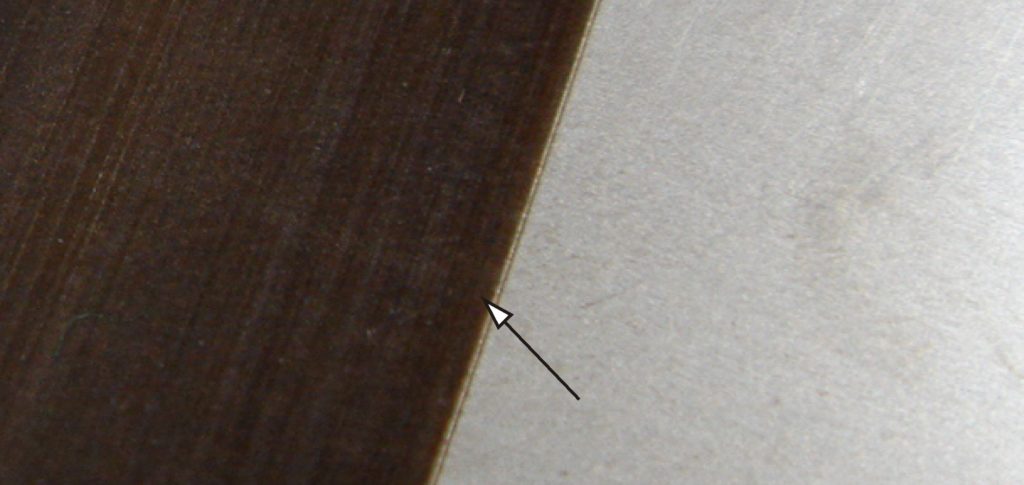

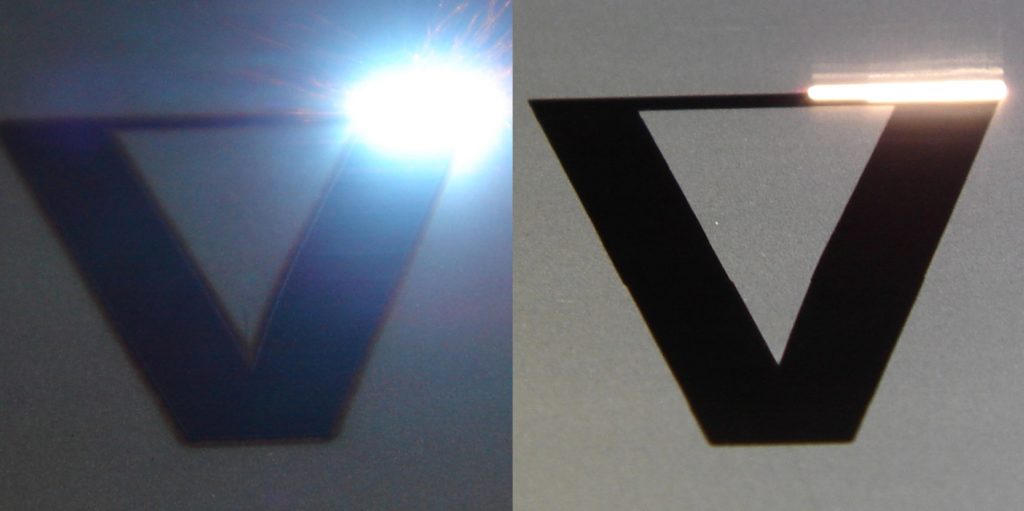

With normal focusing, the peak power is very intense when engraving a piece of metal with a laser. That intensity of laser will inevitably damage the surface of the metal and cause it to corrode. With a process like this, the workpiece usually turns brown after the processing. You can see this below.

To produce the black effects we want, the out-of-focus technique is used to keep the focus away from the material, which reduces the peak power and keeps the laser from damaging the metal surface.

Light and sound of engraving

The laser produces a very bright light when engraving metal at the normal focal distance, and the engraving itself sounds very sharp.

When you take the focus off the surface, the light on the metal starts to dim, and the sound becomes lower. When engraving stainless steel, the light on the metal is orange-red in color, and the sound is not that sharp.

Note: Put your safety glasses on when you observe the light, as the bright light can have long-term, harmful effects on the eyes.

Types of metal and surface treatment

There are many types of metal and surfaces treatments. Different surface treatments lead to different effects on the metal.

When trying to achieve a black mark on the metal, you need to find the perfect focal distance. It’s important to note the light and sound it generates while engraving. If you have any questions about laser settings, contact your equipment manufacturer.