If you currently are printing with a desktop sublimation printer (i.e., smaller than 44″), there may come a time when you want to expand your business’ capabilities. The reason for this could be that you are having trouble keeping up with demand and would like to print more, faster. Or perhaps you would like to expand into new product lines that require larger printers such as all-over T-shirts, cut-and-sew, blankets, etc. To do this, you will want to move into the wide-format printing space, which involves some larger equipment like a 44″ sublimation printer or larger and a large-format heat press to match.

Now, if you have been printing with your desktop sublimation printer and small(er) format heat press for some time, it may be a little daunting to move outside your comfort zone. But don’t worry, here are a few tips for those looking to explore wide-format sublimation printing.

Which printer is right for you?

When you start your search for a wide-format sublimation printer, there are some questions you want to ask.

What size printer do I need?

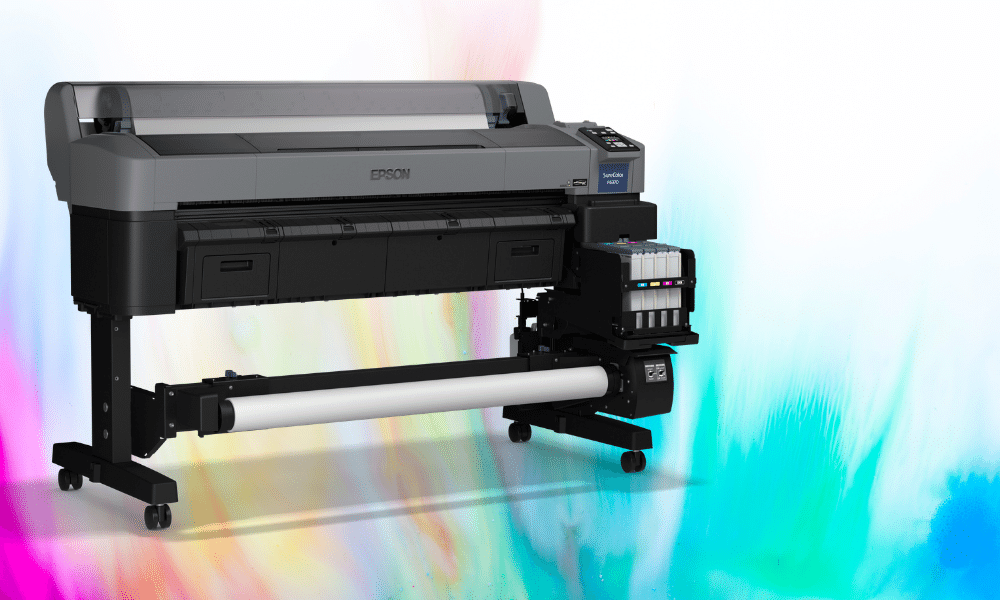

When it comes to wide-format printers, the two most common sizes are 44″ and 64″, which refers to the width of the paper roll they can accommodate. Consider the types of products you are looking to print and how many. If you want to start printing all-over T-shirts, sports apparel, fashion apparel, large photo panels, towels, and pillows, look no further than a 44″ printer. If you’d like to print all of that and also blankets, large fashion apparel, fabric bolts, upholstery, soft signage and more, consider a 64″ printer. Of course, a 64″ is also typically going to be able to print faster than a 44″ given you can fit more products onto a roll (though actual print speeds vary).

What are the features/specs of the printer?

No matter which wide-format printer you go with, most are going to offer similar high-quality prints. You can really get into the weeds of the printer specs, but some of the main things to look at the outside of size are:

- Speed

- Number of print heads (which also translates to speed)

- Maintenance and manufacturer warranty

- RIP software

Concerning maintenance and manufacturer warranty, this can be a deal-breaker. Some manufacturers will offer next-day on-site warranties, which can save you a lot of hassle if you run into an issue right in the middle of production. We know that if you’re not printing, you’re not making money, so definitely consider what kind of warranty and maintenance service comes with your printer.

Lastly, you want to know if the RIP software is included with your printer. If you’ve been printing on a desktop printer, you may have just been printing straight through the printer’s drivers, but with a wide-format printer, you need a RIP. Some manufacturers include the RIP software, whereas others leave an open platform, so you can choose which one you want. All of the RIP software products work well and are generally a matter of personal preference. They will give you excellent results no matter which you choose.

Make sure you have the right heat press for the job

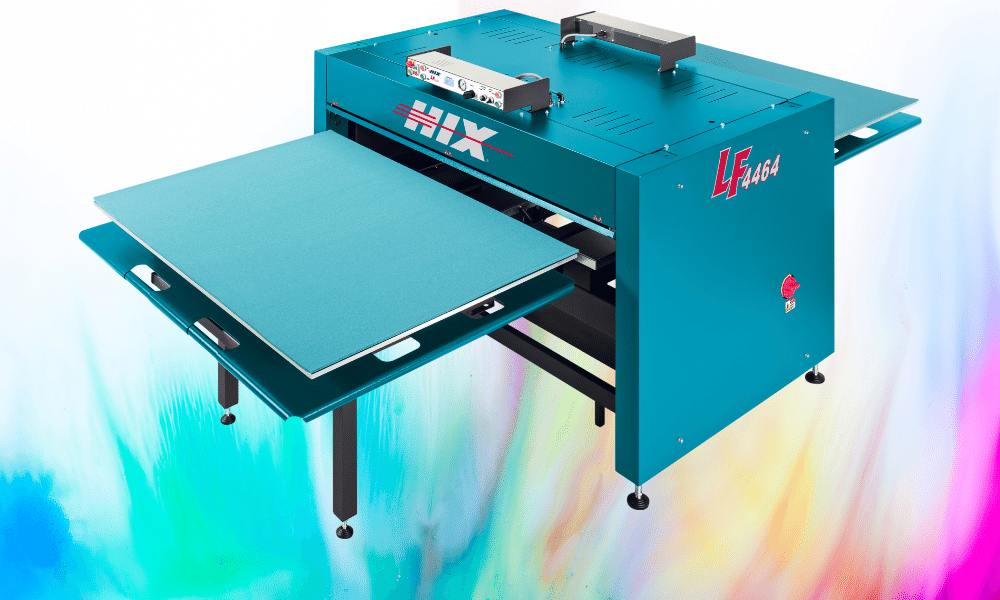

Once you’ve selected your new wide-format printer, don’t forget about a new heat press. While it’s possible to keep using your existing heat press for smaller items, you will need a wide-format press for the larger products mentioned above, and if you’d like to speed up production and press a multitude of products at once. Here are a few things to consider when purchasing a wide-format heat press.

Make sure your press is big enough

Make sure your heat press is big enough for the product you want to produce. Like with printers, it’s essential to consider how big the products you are producing are and get a press that is at least as big if not a bit bigger. There are many wide-format presses on the market going all the way up to presses as big as 54″ X 103″!

Buy a domestically made press (It’s worth it)

Put plainly, your heat press is not the place where you want to cut corners. This is a critical piece of equipment, and a high-quality press will not only last longer but will produce more reliable and better results. With a domestically made press, your initial investment may be greater than overseas, but it will pay off in the long run. You want a press that will provide consistent heat and pressure, translating to quality prints every time.

Make sure your space and electrical requirements are considered

With some of the larger presses (32″ X 43″ and up), you will need to have the correct power installed by your certified electrician. You will also need a forklift on the day of delivery to remove the press from the truck and move it into position at your location. These instructions are provided before purchase, depending on the size of the press.

It’s also important to know how much space you have and if the heat press will fit. There is nothing worse than having a wide-format press shipped only to realize it won’t fit where you need it to go.

Flatbed vs. rotary presses

One final thing to consider is if you should get a flatbed heat press or a rotary press. Flatbed heat presses are likely what you are more familiar with, and the wide-format versions are simply bigger than their small-format counterparts. These are great for printing really anything, including hard-surface items. On the other hand, rotary presses are designed specifically for textiles and soft-surface printing and allow for continuous dye-sublimation. With a rotary press, you can keep sending in mouse pads, doormats, cut and sew fabric sheets, blankets, etc., through the press, and keep production flowing smoothly. Rotary presses are workhorses, but again, they do not allow for hard-surface sublimation.

Wide-format printers and presses are a big investment, so make sure to speak with your supplier and/or manufacturer to get all of the details down before making the jump to large-format. This will help ensure that you and your business are successful in the long run.