For the experienced plastisol screen printer, getting to grips with water-based inks for the first time may feel a little challenging. There are several differences between the two ink technologies. Plastisol inks are often considered an easier starting point for printers. Their PVC or plasticizer-based chemistry means they only dry or cure at high temperatures — so it’s almost impossible for screens to become blocked by the inks.

When it comes to water-based inks, the clue is in the name — rather than PVC or plasticizer, water acts as the primary solvent for carrying pigment. But that doesn’t mean they are harder to use. Water-based inks just can’t be treated the same as plastisol inks.

Water-based ink do’s and don’ts

Water-based inks can’t be topped when it comes to the softness of a print, versatility, and eco-credentials. Here are some helpful “do’s and don’ts” for any screen printer looking to reap the benefits of making the switch.

-

Do … use a water-resistant emulsion to coat your screens

There are few things more frustrating than freshly made screens breaking down soon after you’ve started printing on the press. You can avoid this happening with water-based inks by using a water-resistant emulsion and dialing in your exposure times beforehand.

-

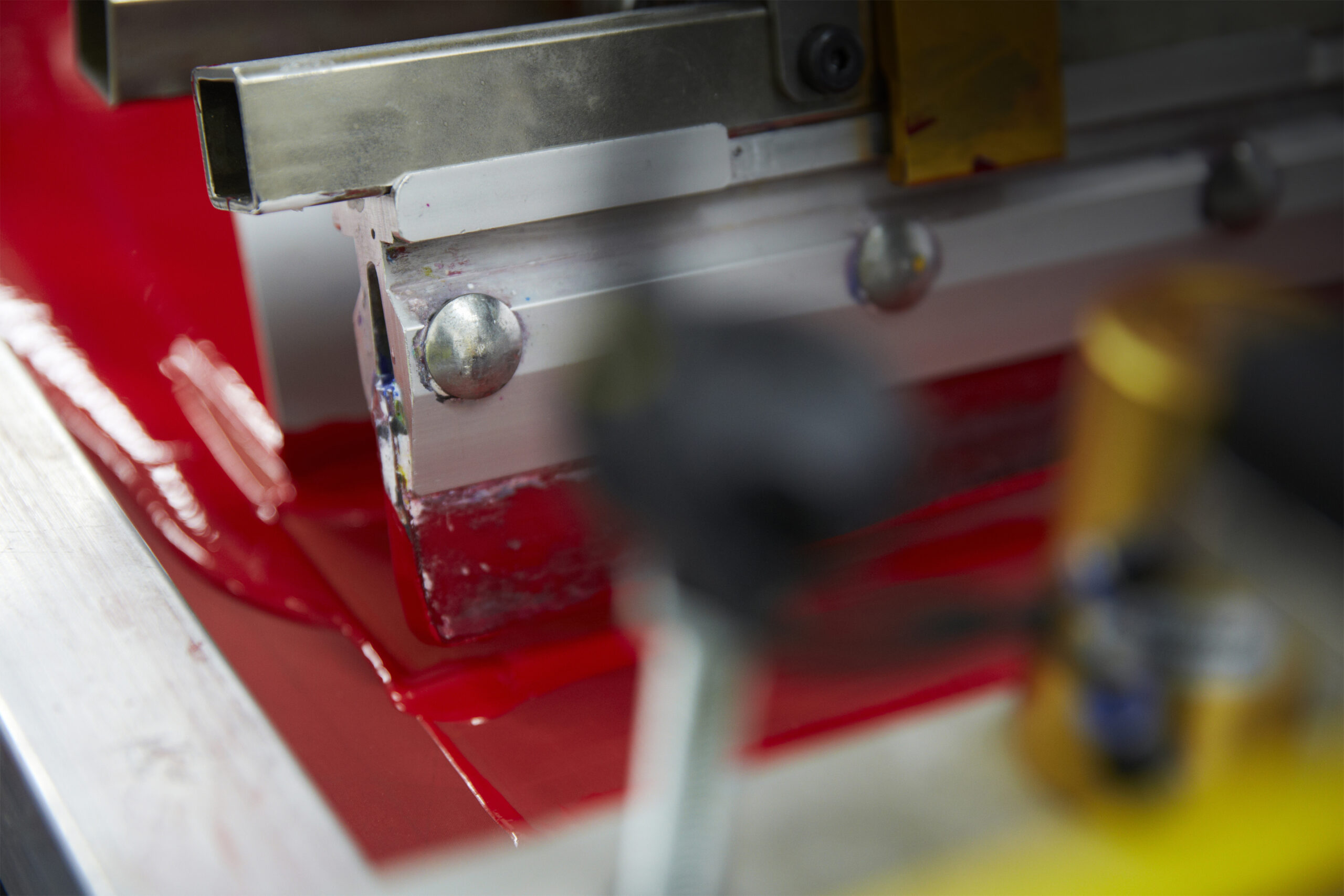

Don’t… forget to flood your screens when taking breaks in printing

It’s a simple process but something easy to forget. If you’re taking a quick break, be sure to leave your screens flooded by keeping ink over the image area at all times. You can also spray a light mist of water over the ink to keep it hydrated. If you’re taking a prolonged break in production, clean the image area with a little water and dry with a clean cloth. Making sure no ink can clog up your screens will solve a lot of headaches down the line.

-

Do … keep on top of your ink management

When it comes to amazing results when working with water-based inks, a little love and care with your ink management goes a long way. Keep on top of the freshness of your inks, maintain a viscosity that’s close to fresh ink, and top up your screens little and often. This will ensure print quality and consistency as well as minimal wastage.

-

Don’t … forget about your heat management

We’ve mentioned ink management, but heat management is just as important for achieving print runs that process like a dream. It all starts with preheating your platens before your production run. We recommend aiming for a consistent temperature of 70°C/158°F on your platens. This will ensure optimum ink performance, flash times, and prevent the ink from drying in the screen. If your platens become too hot, this can have the opposite effect, and screens may become clogged.

-

Do … select the right water-based ink type for the right job

Vector vs. raster artwork. Light vs. dark garments. Polyester vs. cotton. So many factors can dictate what type of water-based ink you should use for a specific print run. High solids are great for large, blocky vector artwork areas and dark-colored backgrounds. Low solids inks are more suited to half-tone printing and light backgrounds.

-

Don’t … forget to have fun!

It’s a great feeling when you’re comfortable with your knowledge of water-based inks and churning out run after run of super-soft hand garments that delight your customers. Remember to make use of the wide range of water-based special effects available to you, including metallics, pearls, two-tones, and much more.