As a company that makes clamshell, swing-away, and shuttle-type heat presses, we are frequently asked by inquiring customers which system would be best. The answer depends on the type of jobs they want to accept, their available space, familiarity with transfer presses, and budget. Each design has unique advantages as well as some drawbacks, some of which can be mitigated or even eliminated.

Your ultimate goal is to pick the system with the right combination of benefits for your intended printing purpose. Here are some opinions you may have heard:

- Swing-away heat presses are typically used for sublimation printing (most popular, sure, but other systems work as well; some advantages are over-rated and some drawbacks can be eliminated)

- Air-automatic, clamshell heat presses are the model of choice in fast-paced, high-production facilities (but benefits differ depending on the application)

- Digital, manual clamshell presses are most popular in a wide variety of applications with small to medium size volume requirements (but other types and benefits should not be overlooked)

- Drawer presses offer the most benefits (they do offer benefits, but most, if not all, can be mitigated, and there are drawbacks)

- Shuttle presses are heavy and unwieldy and take up a lot of floorspace (but they have significant benefits)

No heat press is universally perfect. The pros and cons of each feature of the press must be considered.

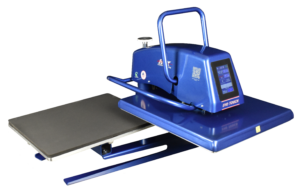

Clamshell presses

Clamshell presses come in standard sizes such as 14” X 16”, 15” X 15, 15” X 20”, and 16” X 20”. This type of press is acceptable to transfer or sublimate on garments or on thin non-textile substrates but generally not adequate to print on rigid, thick, or sublimatable items. The reason is that, when closing, the clamshell press shuts at an angle, creating a pinching effect at the neck (furthest edge) of the press. This effect makes the thicker substrates feel the pressure on that far side first and most, potentially creating an uneven outcome.

To counter this, HIX clamshell presses are manufactured with a “floating” lower platen, slightly tilting front-to-back when closing, allowing them to self-align under pressure.

Clamshell machines occupy a small footprint and are preferred by people and companies with little floor space to spare.

They are also quicker to operate since they only require an up-down movement to cycle (the swing-away machines require an up-down plus an out-and-back sideways movement).

Since clamshell presses open at an angle, the heat casting partly faces the operator when in the open position, radiating its heat forward, thereby creating discomfort for the operator (especially on warm summer days). This is particularly true for castings coated with non-stick PTFE (i.e., Teflon). This is one of the reasons why HIX does not coat its castings.

Swing-away presses

Swing-away presses allow the user to swing and move the heat head away from the working surface, clearing the lower surface area. When closing, the heat head lowers vertically onto the substrate, eliminating any possible pinch points.

Standard sizes are 15” X 15”, 14” X 16”, 16” X 20”, and 20” X 25”. The larger 20” X 25” can nearly simulate an all-over print on a garment. This over-size is also ideal to “gang up” a number of smaller projects that can all be pressed at the same time (with the same pressure and time), such as tiles, ceramic ornaments, smaller Chromaluxe plates, sublimatable bottle openers, and other small, flat substrates.

Swing-away models require more space clearance for the swing-out motion and are slower to operate because of this extra movement.

Swing-away models generally feature a straight down pressure system with a handle that makes the swinging, closing and opening possible. The same straight down pressure allows for projects that require higher pressure and/or precise placement easier.

Swing-away models, because of their vertical downward closing, are also able to provide more clearance which is needed for thicker fabric or other non-textile substrates up to 1 ¾”.

Some operators prefer the swing-away press over the clamshell because of the greater clearance of the hands (and knuckles) away from the heat source. This is partially true but quickly learned to be avoided.

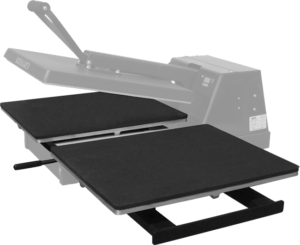

Pull-out/slide-out drawer presses

Presses with pull-out or slide-out drawers could be considered a variation of the clamshell or swing-away presses since these presses open in either of those two ways. However, since the drawer is not built as an option but as part of the original construction, and also because some customers view them as a separate type, we will deal with them here separately.

The first benefit of being able to pull out or slide out the lower platen is that this allows the operator to load the machine away from the heat source.

Loading the shirt away from the platen can be comfortable in as far as the press radiates heat toward the operator. As indicated earlier, heat radiates more liberally from a coated plate, in which case the drawer would create a more distant and comfortable operation. But as we saw earlier, removing that coating would also remove the need for this feature.

A further advantage is that the lower, in this extended position, lends itself better to pull the shirt over and around the lower platen, i.e., “splitting” the shirt.

An alternative to this would be to install a cantilever pedestal or “splitter stand” on a standard clamshell or swing-away, thereby removing the need for this feature as well.

Since HIX presses are not coated, and almost all come with included or optional splitter stands, drawer presses are not a model you’ll find in our catalogs. Additionally, there are also drawbacks.

The first downside of the slide-out drawer is the extra movement added to the cycle. Customers are often, at least at first, endeared with the feature but quickly abandon the extra step backward and forward (while sliding the drawer in and out) in the interest of time.

Structurally also, clamping down a press on the roller bearings of the drawer mechanism is not as solid as closing the press on a firm steel base.

Shuttle presses

Shuttle presses can be seen as a cross between a clamshell and a swing-away or as a better variation of a swing-away press. In this case, however, the press swings not just away from the original platen but moves onto and over the next lower station.

Presses exist in two variations: either the upper heat head moves left-to-right between the first and second fixed lower, or the heat head remains fixed with the lowers moving on a shuttle system left to right. The mechanics are a bit different in each case, but the result is the same: the operator virtually doubles his capacity by working on alternating lowers while the press cycles through the timed compression.

Some presses can be expanded into this shuttle system by adding a second lower and attaching a shuttle assembly (see our accessories to the HIX N-880).

The advantage of this shuttle press is its added efficiency. The downside is that, because of the added complexity of the press, the ticket price is higher, albeit still less than the cost of two similar presses.

In summary

| Clamshell | Swing-away | Drawer | Shuttle | |

| Pros | faster speed | vertical visibility | no heat-proximity | increased efficiency |

| small footprint | reduced heat hazard | threading the shirt | no heat proximity | |

| comparatively lower cost | not facing heat source | reduced heat hazard | ||

| Cons | facing heat source | slower speed | added cost for little or no added benefit | added cost |

| pinching at neck | larger footprint | weaker construction | larger footprint | |

| higher heat hazard | comparatively higher cost | slower speed |