Professional filtering fume extractors are often bundled with laser engravers as “ready-to-run” packages or recommended as key accessories. It may seem obvious that you don’t want your room to fill up with smelly smoke, but it’s important to understand what real risks are present if you don’t use one.

Health risks of laser engraving

A laser engraver uses a concentrated light beam to “burn” away material from the target. The interaction between the light and the target material results in a desirable visible mark and two undesirable and unavoidable byproducts:

- Inhalable dust

- VOCs

Inhalable dust

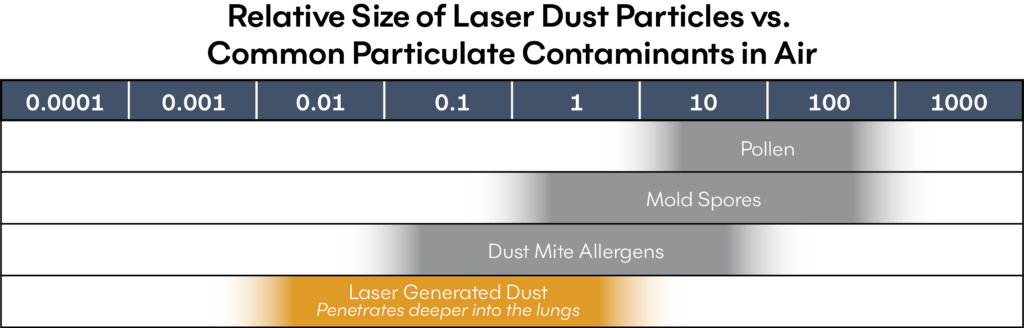

A large proportion of laser emitted dust is within the inhalable dust range, in particular, the PM2.5 range: fine inhalable particles, with diameters that are generally 2.5 microns and smaller.

What are the harmful effects of PM2.5? According to the EPA, PM2.5 poses the greatest risk to a person’s health. These particles can embed themselves deep into your lungs, and some may even get into your bloodstream.

The HEPA filters installed in professional laser fume extractors have an efficiency rating of 99.999% at 0.3 microns. This means that it removes 99.999% of the most aerodynamically penetrating particles, known to be 0.3 microns, while smaller and larger particles are even more effectively captured, resulting in extremely clean air free of respirable dust. Without this type of filter, your lungs will be completely exposed to these deep penetrating particles.

VOCs

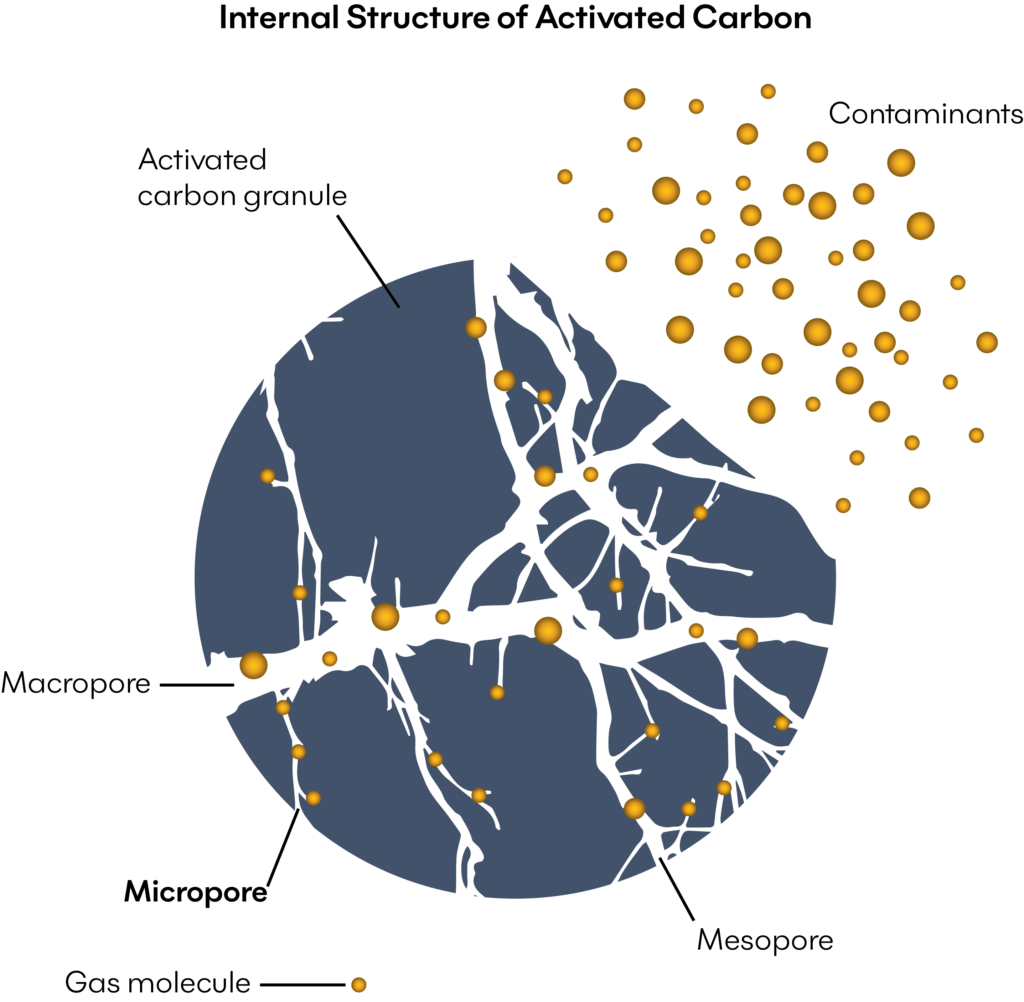

Volatile organic compounds (VOCs) are compounds that have a high vapor pressure and low water solubility. VOCs are emitted as gas molecules from certain solids, liquids, or when a laser burns the target material. Some of these VOCs may have a wide range of short-term and long-term adverse health effects.

Depending on the target material, a laser can generate relatively low VOCs and sometimes very high concentrations of it. In either case, the EPA’s Total Exposure Assessment Methodology (TEAM) studies have found that elevated concentrations can persist in the indoor air long after the activity is completed. It is understood that these VOCs can accumulate in a room without proper gas phase filtration.

Proper laser fume extractors have gas filters that contain substantial amounts (15-80 lbs) of activated carbon blends to adsorb and treat the VOCs in the airstream.

Premature laser wear and shorter maintenance intervals

Every laser engraving system requires cleaning and maintenance. However, if the fumes (particulates and VOC contaminants) are not properly evacuated, the bearings and optics of the system can get fouled up quite quickly. This puts a strain on moving parts, motors, electronics, and can even permanently damage the sensitive lenses and mirrors. Proper fume extraction quickly evacuates the contaminants so that they are less likely to settle on these components.

Unhappy employees

Aside from the scary possibility of unhappy employees unexpectedly quitting, an extensive study into happiness and productivity has found that workers are 13% more productive when happy. The research was conducted by Jan-Emmanuel De Neve (Saïd Business School University of Oxford), George Ward (MIT), and Clement Bellet (Erasmus University Rotterdam). It’s easy to see how employees could become unhappy working in an environment with poor air quality and greater health risks. Installing fume extractors with proper air filtration can easily make the workplace safer and more pleasant.

Caring about the work environment and beyond is an opportunity to engage your employees and make them part of the big picture. One of the best benefits you can provide to your employees is the opportunity to make a difference in the world while working. Make the fight against air pollution part of the company culture. Using laser fume extractors with recirculating air filtration eliminates the laser process’s contribution to indoor and outdoor air pollution. Your team can feel good working in a safe environment while feeling like they are doing their part in improving the environment for others.

Poor community citizenship

Your community may be within the building you share with other tenants or the neighborhood in which your company is situated. Without appropriate filtering fume extractors, the contaminants from lasers can diffuse or get entrained in the ventilation ducts into other facilities within the building. Alternatively, if you are pumping the contaminates straight outside without filtration, the toxic air can also reach a neighbor’s fresh air intakes or open windows.

Not respecting the comfort, health, or property of others in the community can lead to a negative reputation. Worse still, personal conflicts with members of the community can suck precious energy and time from your business and can even escalate to legal actions.

Be a respected and responsible citizen and avoid these risks by proactively capturing the contaminants at the source with a filtering laser fume extractor. It will be an investment in your health and success.