Your laser engraving/cutting machine’s efficiency and productivity depend mainly on how well it is maintained. Smoke, dust, or residue build-up inside the laser system or the mechanical components can cause several otherwise avoidable issues.

If you examine your machine only when it has started malfunctioning, you will lose the time and efforts it takes to troubleshoot and fix the problem. Therefore, it’s always good to regularly follow the maintenance manuals and make sure you use quality machine parts.

Here are some basic maintenance suggestions for your laser machine to keep its quality output, consistent reliability, and extended product life.

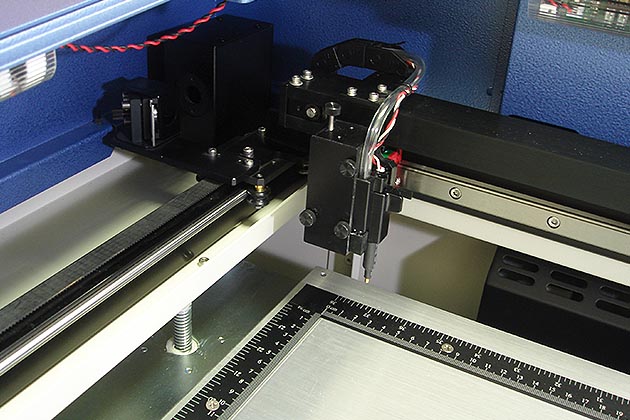

Cleaning the worktable and motion system

- Turn the power off and unplug the laser machine.

- Use a vacuum cleaner with a flexible nozzle to remove dust and debris from the worktable and motion system.

- Dampen a paper towel or cotton towel with a small amount of all-purpose cleaner, alcohol, or acetone to clean the working table and the motion system’s rails.

- Wait for all cleaning residue to dry completely before plugging in and operating your laser machine.

Pro tip: Never pour or spray oil, alcohol, or acetone directly on the worktable, as this may lead to fires or soot build-up if improperly used.

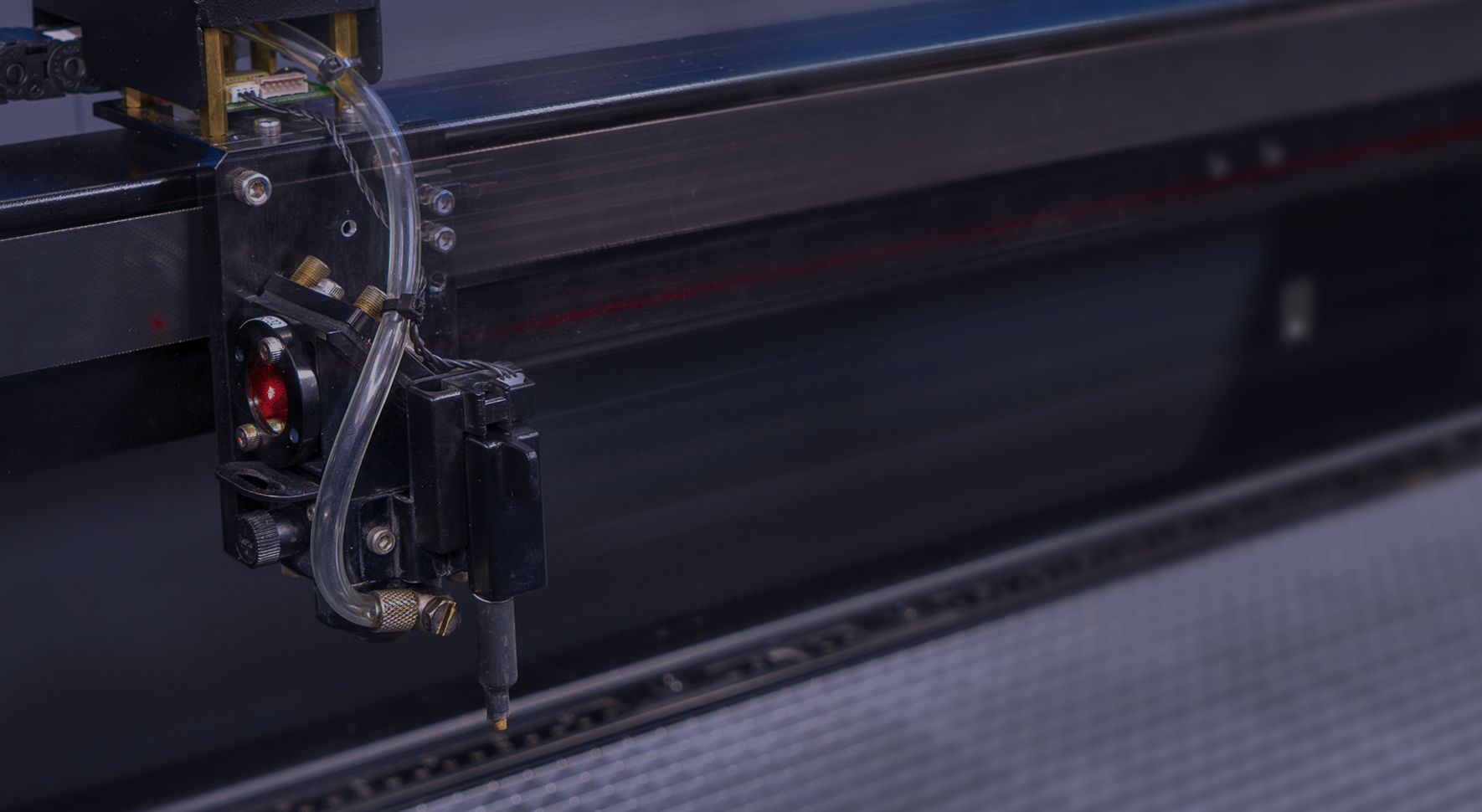

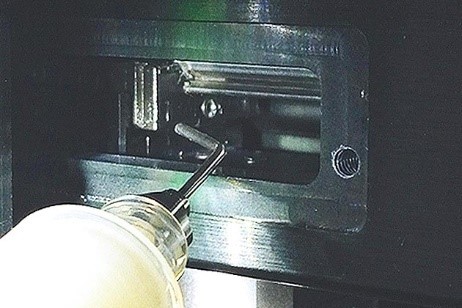

Lubrication of the X/Y rail system

- Clean and lubricate the X linear rail of the laser machine with 0.1ml of grease using a syringe every two weeks to maintain the motion system properly.

- Always clean and lubricate the X and Y rails after working with materials that produce a lot of debris like wood.

Pro tip: Too much oil or NSK PS2 grease applied to the Y rails accelerates the debris building up.

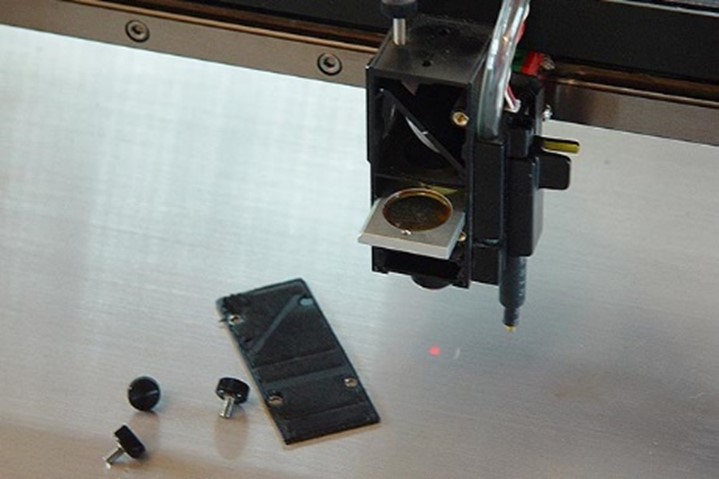

Cleaning the mirrors

After you have removed each mirror, you will want to inspect each mirror for scratches, soot, or debris.

- Hold the mirror with the reflective side up without touching the reflective side. (Do not apply any finger pressure or any other cleaning solutions to the mirror surface.)

- Drape a new sheet of lens tissue over the mirror.

- Apply a few drops of lens cleaner on the tissue covering the mirror. (Apply enough so that the tissue absorbs just enough solution to cover the mirror surface.)

- Pull the tissue across the mirror in only one direction.

- Make sure the mirror is completely dry before reinstalling it.

Cleaning the focal lens

The recommended lens cleaner is Eclipse Cleaning System Solution from Photographic Solutions or HPLC grade methanol.

- Clean the focal lens with a cotton swab and lens cleaner solution. Be sure to clean both sides of the focal lens.

- After cleaning, use a cotton swab to dry the focal lens and lens cover gently.

Pro tip: Do not apply any finger pressure or other cleaning solutions to the lens surface.

Cleaning the exhaust duct

Efficient exhaust ventilation is crucial to laser cutting quality. I suggest cleaning the exhaust duct of accumulated dust regularly, as it helps maintain your laser machine’s ventilation efficiency.