Laser cutting is becoming an ever-popular process within the manufacturing industry due to the low overhead and processing versatility. Lasers are capable of cutting and marking woods, leather, fabrics, plastics, acrylic, metals, foams, and more. This wide range of processing materials makes laser machines a great asset in many manufacturing facilities.

Laser systems: CO2 and fiber

To discuss the more in-depth differences between cutting metals versus non-metals, we must first have a general understanding of laser systems. In general, there are two types of lasers: CO2 and fiber. Both CO2 and fiber lasers initially create light in the same way — by exciting the atoms of a gas mixture contained in a laser tube (Fig. 1) (usually made of glass, ceramic, or metal) until the atoms create particles of light. This light is then bounced around in the same chamber until an adequate amount of light (or wattage) is created. This beam of light is then directed out of the tube and into the optic assembly, or head of the laser, where optics shape the beam and direct it into the material.

Fiber lasers

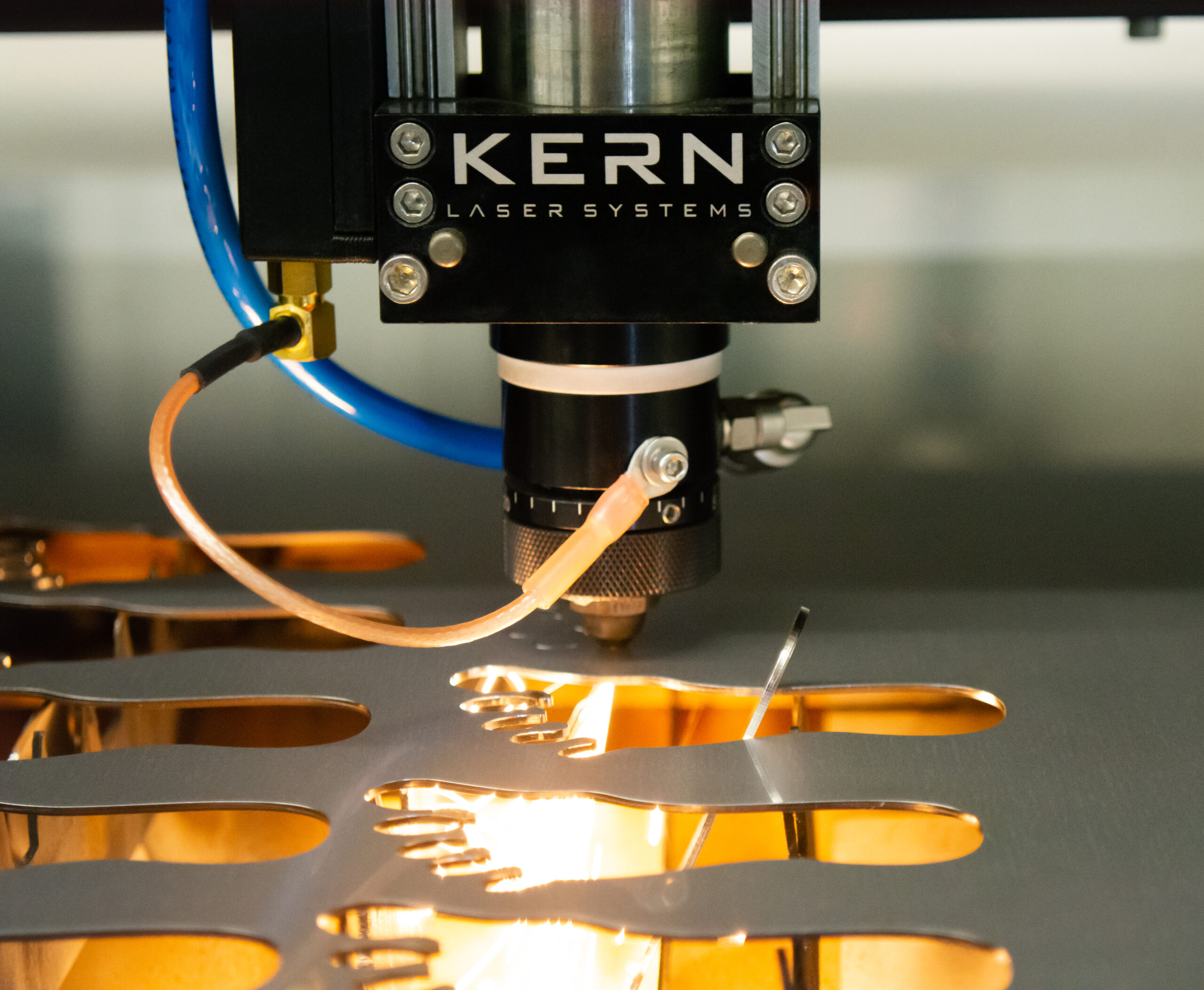

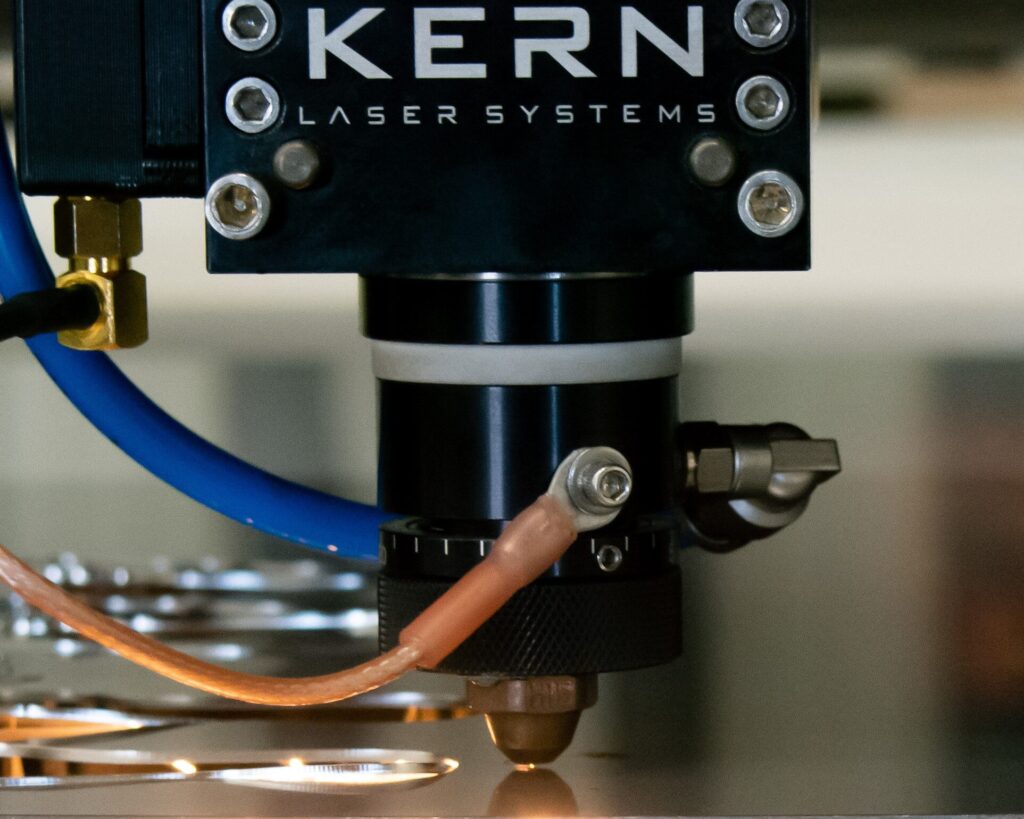

For fiber lasers (Fig. 2), this beam travels along a cord of fiber optic lines, similar to those used in fiber optic lights (Fig. 3), that are encased in rare-earth elements such as Ytterbium (most common), Thulium, Holmium, Dysprosium, Erbium, and Neodymium. These encased fibers allow the beam to travel from the origin point to the head of the laser while maintaining its level of energy. The beam is then defined and shaped in the optic assembly via lens before being directed into the material being processed. Fiber lasers are generally high wattage — 500 watts and up — with some being over 20 kilowatts (20,000 watts) and are typically used for high-production facilities dealing with sheet metal. They are also the preferred laser option for thicker, highly reflective metals such as copper or mirrored stainless steel.

CO2 lasers

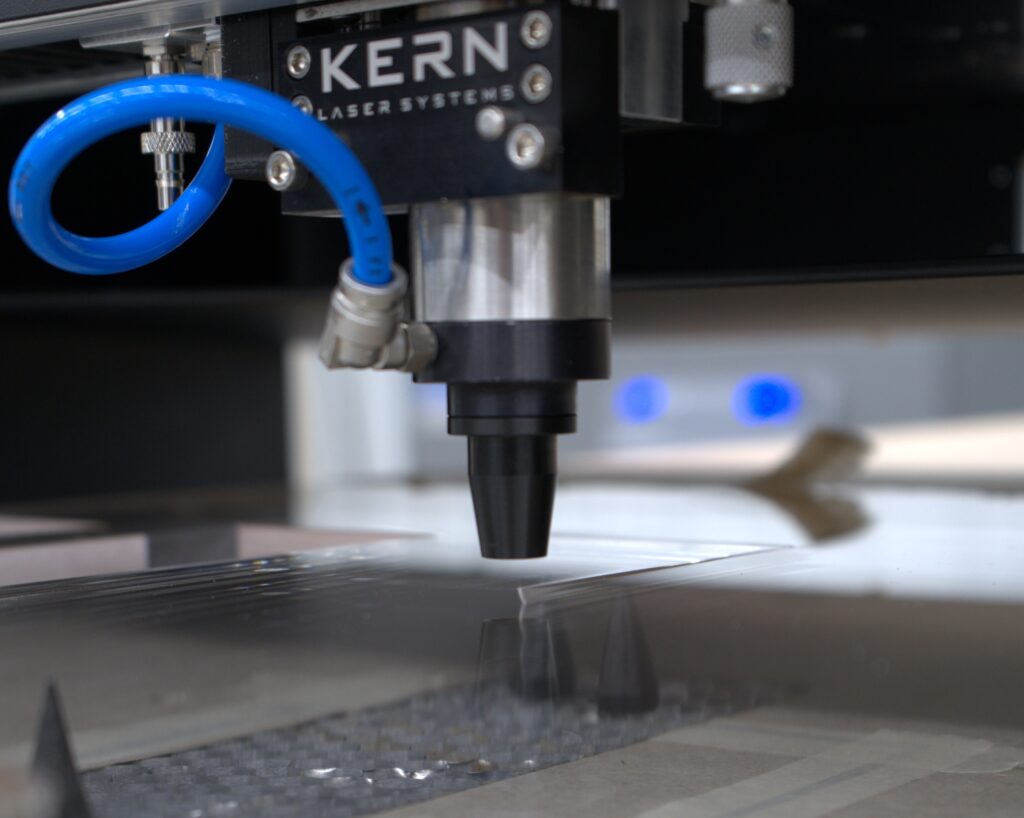

CO2 lasers (Fig. 4), on the other hand, use mirrors to reflect the beam created in the laser source instead of fiber optics. These mirrors not only reflect the light back and forth throughout the tube of the laser source but also direct the beam out of the tube and into the optic assembly. Once directed into the optic assembly, the beam is focused through the lens and into the material.

Metal vs. non-mental cutting

Moving forward discussing metal cutting, the information applies to both fiber and CO2 lasers — and non-metal cutting information refers only to CO2 lasers.

Laser head

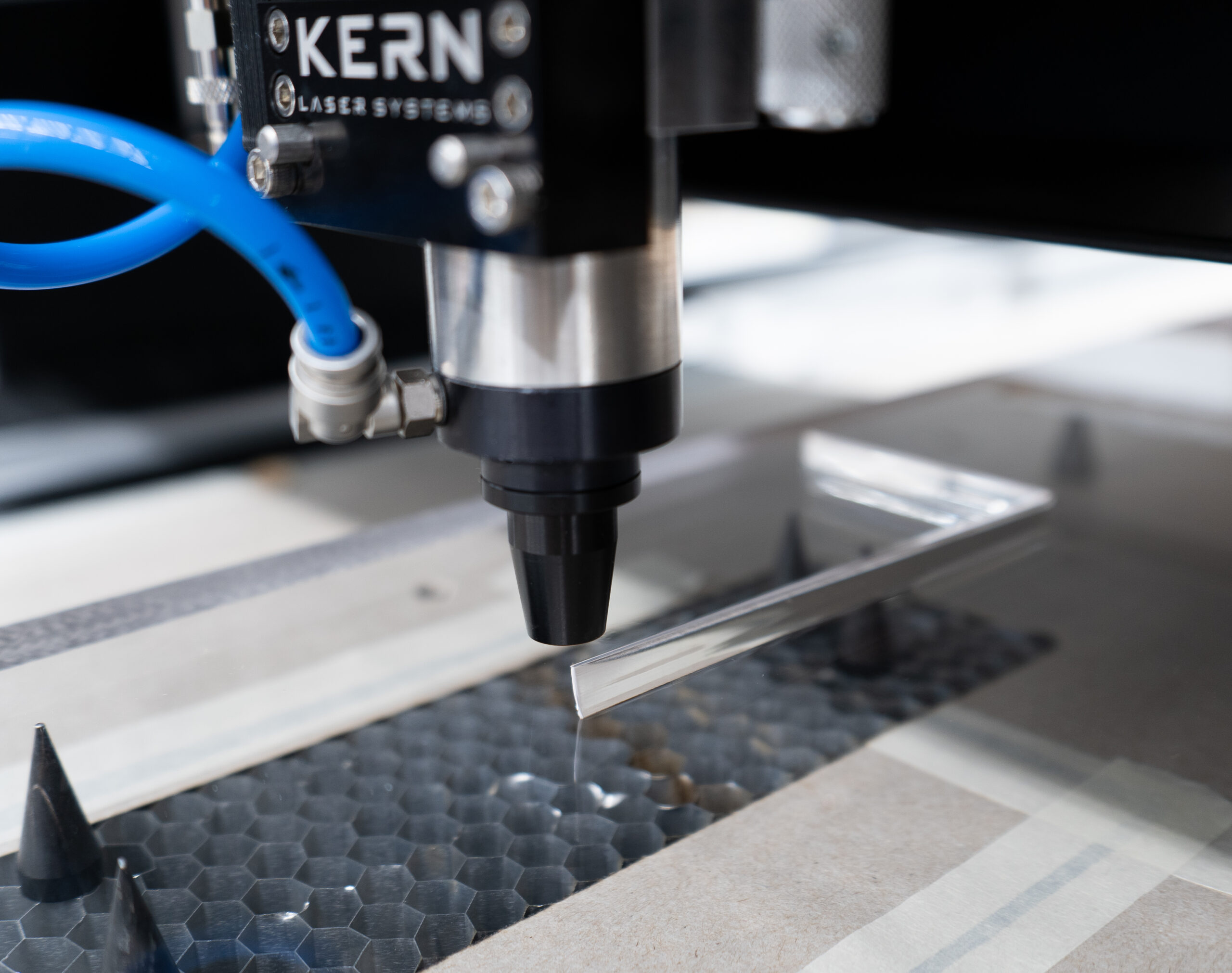

One of the main differences between these two processes is the laser “head” or assembly, as shown in the images above. A dial allows for minute adjustments to the focus with the metal cutting assembly. You may also have noticed that the nozzle on the metal assembly is copper versus the aluminum nozzle of the non-metal cutting assembly. The copper nozzle is used for an automatic height follower, which senses the surface of any metal and continuously maintains the focus height over any physical changes on the surface of the metal.

Alternatively, non-metal cutting does not yet have the capabilities for automatic focusing, so non-metal objects that are being processed need to be as flat as possible to maintain the focus height that is manually set by the operator. The differences in these nozzles also come into play when we talk about focus, which is another key factor.

Beam focus

Your beam focus is another key difference in metal versus non-metal cutting. For non-metals, your focus height is, in general, always the same distance that is measured with a spacer that is 0.22″ thick — setting the tip of the cutting assembly exactly 0.22” away from the surface of the material (Fig. 5). This allows for proper airflow and ensures the material is being pierced and cut with the thinnest point of the laser beam.

For metals, the focus is a bit more complicated, as different metals require different focus depths, but in general terms, your focus should be between 0.010″ to 0.020″ from the surface of the material being processed — or about the thickness of a gift card (Fig. 6).

Settings

Metal cutting requires some additional settings that non-metal cutting doesn’t need. These settings are “assist gas” and “pierce.” To have a dross-free cut, metals require an assist gas of either Nitrogen, Oxygen, or clean, dry shop air. This assist gas is blown through the nozzle alongside the beam and into the cut, helping to keep debris away and creating a clean, precise cut.

Your pierce settings are also an incredibly important part of metal cutting, as the laser beam needs to pierce the material before moving onto the cut. The pierce allows the beam to cleanly cut through the dense (and potentially reflective) metal in a focused spot — which means the rest of the cut is easier as the beam is already through the material. Then it just continues to melt the material away as it moves through the cut.

These settings are not necessary for non-metals, but non-metals tend to need adjustments to the laser’s frequency to help produce a clean cut.

The main difference between metal and non-metal cutting is that metal cutting with a CO2 or fiber laser requires a specific cutting head, a finer focus, and two additional settings: pierce and assist gas. We hope this article gives you some basic insights into cutting metals versus non-metals with laser systems!