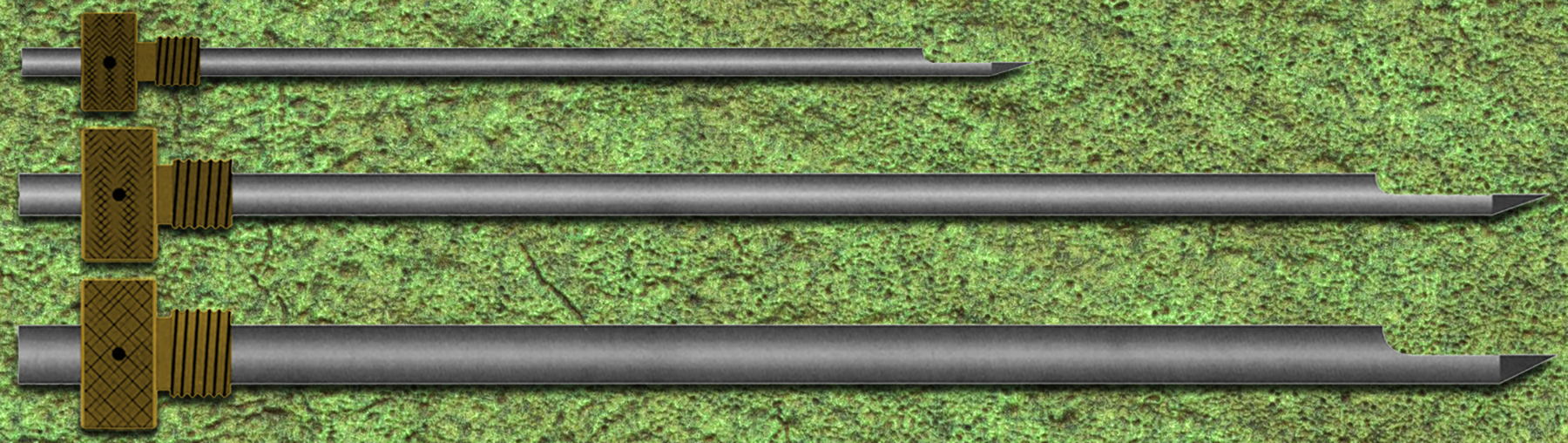

To make sure you’re keeping your rotary engraving equipment in tip-top shape, here’s some cutter guidance to consider.

- Keep your cutters sharp and have a couple extra of the ones you use the most

- Use a set of cutters to cut only plastic and another set to cut metal (A plastic cutter may go years while cutters used on metal may dull on the first character)

- Adjust all cutters to the same length when setting/adjusting the initial zero

- After that, you can change out the cutter to a larger tip size with no readjusting (Cutter length adjusters are available)

- Set one cutter and set tool, then use the tool to set the rest of the cutters

- If you do a lot of metal engraving, get a cutter sharpener