I had to laugh when I got this question for this article, as it came at a perfect moment. I was giving a private workshop at The Wrap Institute Center in Munich, and a shop owner taking the class, who lives in the Middle East, was just finishing a business trip in Europe. He bought a massive amount of wrap tools to bring back to his shop. Near the end of the second day of training, he asked me why I didn’t use more than five to six tools. I said that once you get the right knowledge of the material and a bunch of techniques, all you really need is just a few specific tools. He sighed and said he wished he would have known this before spending a ton of money.

So, with that, here are the core car wrapping tools that create a really nice workflow.

Two squeegees: medium and soft

Having two squeegees with different hardness allows you to adapt to each application. For flat surfaces, like box trucks and trailers, a medium squeegee can mean less fatigue over the course of the day. For curvy vehicles, a soft squeegee easily conforms to the surface for high workflow and quality.

Squeegee buffers

Having a variety of quality squeegee buffers can help the installer adapt to each job. The key is to get a thin, durable buffer that can be used wet or dry and comes off with no adhesive residue. The main thing is to put on a new buffer for every wrap to ensure high quality.

Knife

The main thing to remember when wrapping is that an installer will use between two to five blades per vehicle. This means having a multi-cartridge knife is a big time saver as the installer doesn’t have to stop their workflow when a blade needs to be replaced.

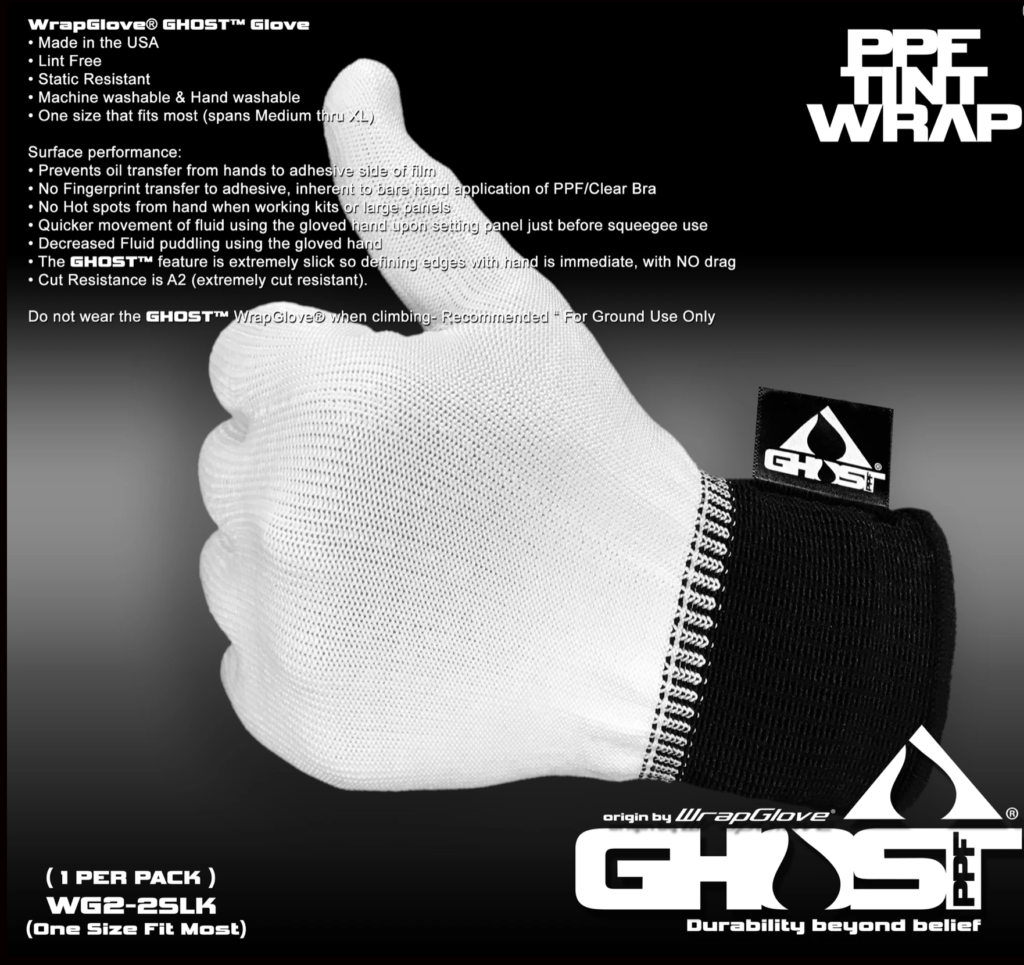

Application glove

A good application glove can really speed up the installation process, especially if it is made out of the new fabrics that were introduced recently. These fabrics allow the glove to slide without the need of adding a soapy solution.

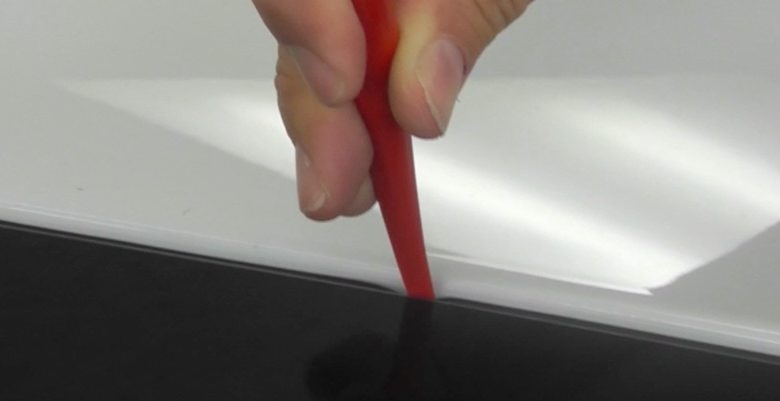

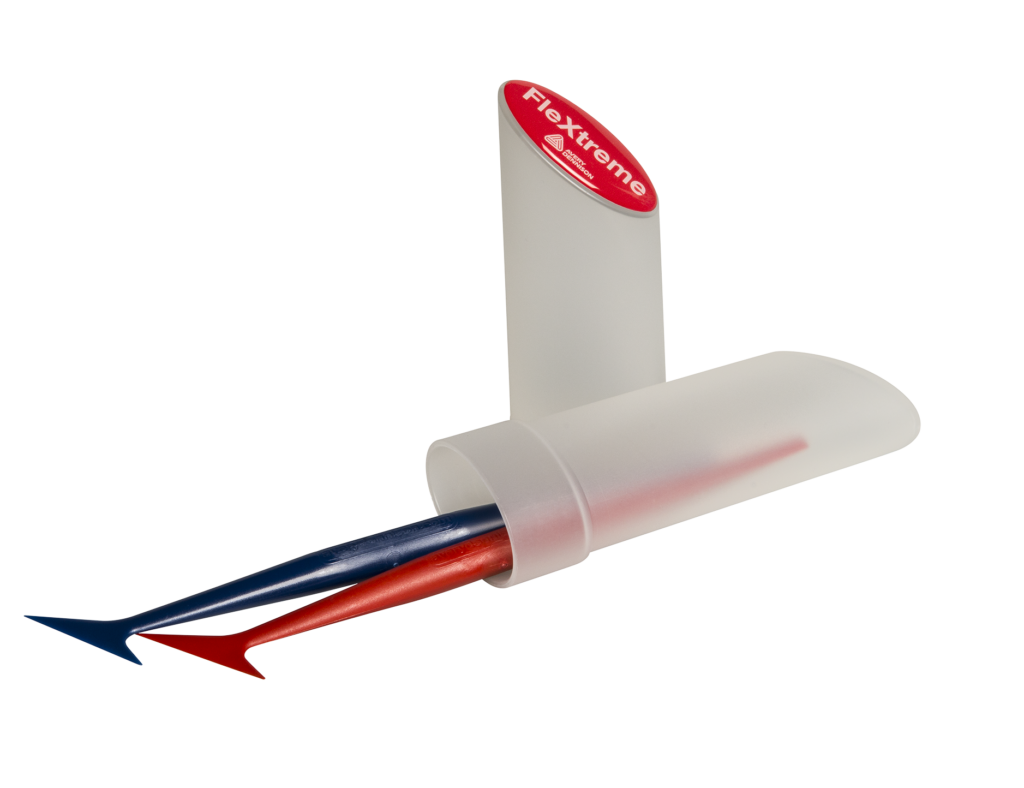

Micro-squeegee/tucking tool

These are amazing tools for getting the material behind rubber gaskets and achieving a strong corner game. The key is, much like the squeegees, to have two—one medium and one soft. The medium works great for tucking behind gaskets and the soft for corners.

Heat gun

For years, I used a propane torch for wrapping, but I have been using heat guns more and more. I can do more with a heat gun; it’s safer than a torch, and you can’t post heat with a propane torch, so you’re going to need a heat gun at some point. If you buy a heat gun in the $70-$100 range, this seems to be the sweet spot in terms of quality and durability.