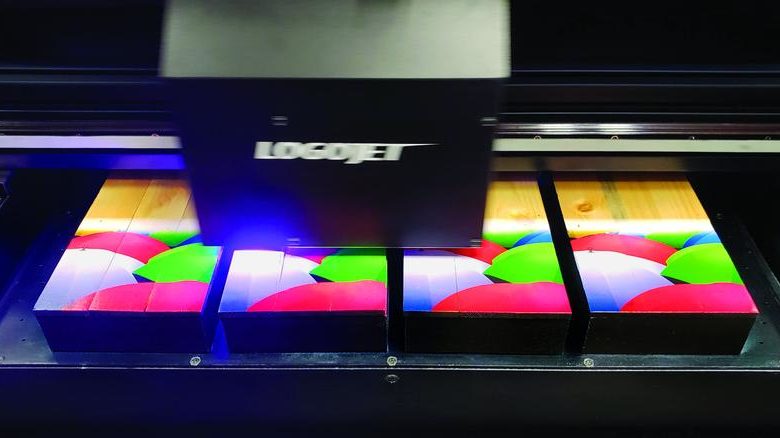

Like it or not, we live in an age of rapidly evolving technology where it’s become essential to diversify to stay ahead of the competition. In our industry, the methods of decorating products and substrates are constantly advancing, with greater capabilities than ever before. UV-LED direct-to-substrate printing is one of the fastest-growing segments in the printing industry — offering advantages when it comes to cost, print quality, and the ability to customize unlimited types of substrates. But how do you go about introducing UV printing into your existing business, and what do you need to consider before taking the leap?

Why do you need UV printing?

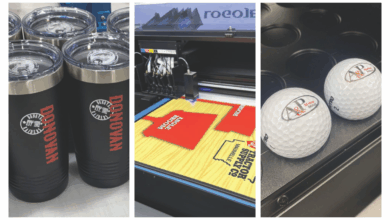

First of all, you should ask yourself why you need a UV printer. Are you looking to replace outdated equipment, expand your production capabilities, or increase profitability by reducing the amount of business you outsource? Traditional methods of decorating awards and gift items include laser engraving, sandcarving, screen printing, and sublimation. UV printing can either be used as a replacement or as a complement to these techniques to add full-color, white ink, textures, and special effects to finished pieces.

The ability to personalize customer-supplied items or odd-shaped pieces gives UV printing an advantage over a few other methods. Some UV printers also offer rotary printing capabilities for decorating the entire circumference of cylindrical objects and tumblers.

What will it cost?

With the potential to customize any product on the spot with unlimited colors in a single step, a UV printer can save you a huge amount of time, manpower, and, ultimately, money. But, as the saying goes, sometimes, “You have to spend money to make money.” For small- to medium-sized business owners, a quality UV printer is a major investment. Some of the smaller models are available for under $20,000, ranging all the way up to $100,000 for larger format flatbed UV printers.

It’s important to first determine which substrates you need to decorate, the size capacity, and the print capabilities you require, and then find the right fit for your needs. You will also want to factor in the cost of consumables including annual parts replacement and ink, which could add up to a few thousand dollars per year. Many UV manufacturers offer the option to lease equipment instead of purchasing, which can be beneficial if you don’t have a lot of cash upfront.

It may prove advantageous to your workflow to have a dedicated laptop loaded with the software needed to run the printer, including design applications for creating and editing artwork files, as well as print drivers and RIP software required to run the printer. Most UV printers are fairly compact and don’t require a huge amount of space, but you’ll want to make sure you have an area set aside in a clean, climate-controlled environment to keep your printer protected from humidity and dust. You’ll want to treat your UV printer more like a supercar in contrast to some of your other equipment, which may be more comparable to a sturdy off-road vehicle. Fortunately, there isn’t much other supportive equipment needed for UV-LED printing, so you can quickly get up and running and on to decorating everything in sight.

What’s the learning curve?

If your current capabilities only include laser engraving or sandcarving, expanding into UV printing is a whole new ballgame. For others who have already branched out into screen printing and sublimation, the learning curve may be a little smoother. Learning how to manage colors properly, navigate RIP software, and maintain high-tech machinery can take some time. You need to decide if your current staff has the background knowledge to make an easy transition into UV printing, or if it makes sense to hire someone with design and print training.

During the research phase of your UV printer purchase, you may want to visit the manufacturer’s headquarters for a one-on-one demonstration of the equipment, or at the very least attend a trade show where you can see the printer up close and the steps needed to run it. Many manufacturers provide onsite installation after purchase, including hands-on training and education for all employees involved in running the printer. There may also be training tutorials and how-to videos for printing techniques or part replacement, in addition to call-in or webcam support to walk you through any issues

What else should I consider?

While a UV printer is a considerable investment that can significantly increase your profits, you shouldn’t plan on it paying for itself overnight. Be prepared to do more than just transfer your existing business over to UV printing. Find ways to expand your line and add value to the products you offer by doing something that your competition can’t. Identify your market and find out what your customers want. They will gladly pay extra for the additional options UV printing can offer.

The number one answer given by those in the awards industry when asked what’s most important in choosing a UV printer is support. Most UV printer brands have comparable pricing and printing capabilities, but there’s no question that you need to deal with the manufacturer on an ongoing basis for support or repairs during the life of your printer. Make sure you’re comfortable with the people you deal with during the buying process and you can trust them to stand behind their product and continue to support you in the future. It’s always a good idea to ask others in the industry who have already ventured into UV printing for recommendations and advice while making your decision.

The most important thing you will invest in when adding UV printing to your business is your time. As with any complex piece of technology, it takes time to learn how to make full use of all the exciting features of a UV printer. It also takes trial and error, and lots of practice to learn effective techniques for printing on various types of substrates and different-shaped objects successfully. Be prepared for some downtime or delays in production during the learning curve and plan accordingly. If you take the time to do your homework, you’ll soon be an expert in UV printing, and your bottom line will reap the benefits.