One problem for sign makers is knowing a priori how much “light” is coming out of their sign. Many light intensity regulations are based on white or broad-spectrum lighting. There is no standard conversion for determining light output for colored faces using red, blue, and green LEDs. Light from a sign is measured in illuminance. This is a measurement of surface brightness and is typically measured in NITS or LUX (lumens per square meter).

On the surface, you may say, “That is simple. I know the lumens of each LED in the sign and the surface area of the sign; therefore, I can just perform a simple calculation.” Well, it is not that easy, and several factors determine the actual LUX measured at a sign face:

The quantity and intensity of the LED module

This is the simplest part of the equation. Often the issue is finding LEDs that are not too intense for shallow letters that require a larger number of LEDs to get even illumination.

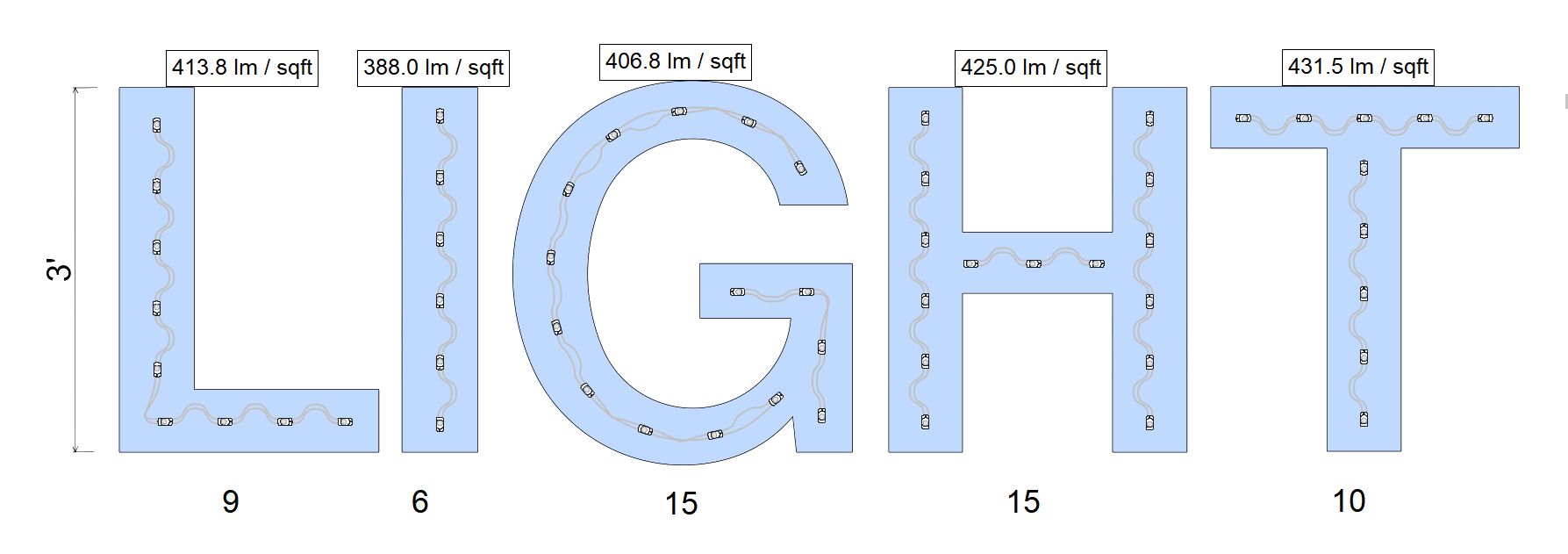

Sign shape and dimensions

Light drops off as an inverse square of the distance from the sign face. This non-linear relationship means that if you double the distance, you decrease the light by four times. The distance not only depends upon the physical distance but the optical beam angle of the LED module. Other factors that impact “distance” to the surface are the stroke of the sign and the beam angle of the LED.

Sign materials

The optical transparency of the face material (or materials if you have a secondary vinyl overlay) will also affect the sign LUX. Acrylic, polycarbonate, flex face material, and digital printing all have varying levels of optical transparency. Optical transparency can also vary with material thickness. Another factor is the paint type and reflectivity inside the sign. These face materials combine to improve the quality of the light, with diffusion and a reduction in glare, and the return material helps direct the light forward.

Light meters that measure LUX and foot candles that are less than $50 are worth the investment to confirm the sign illuminance is within compliance.

As sign companies face more pressure to comply with a range of illuminated sign requirements, the industry will see significant innovation around IoT and control, estimation tools, and a broader range of color and color temperature options to help meet the ongoing needs and challenges of sign fabricators. Regardless, knowing what variables drive illuminance at the sign face, planning, and using simple tools such as a LUX meter to verify illuminance before completing the sign will help reduce frustration and time and ensure the project complies with any illumination regulations before installation.