If you own a custom apparel business, you’re making hundreds of decisions on a daily basis. In order to be successful, owners and operators need to have the right systems and processes in place. Having systems in place not only leads to efficiency but also the ability to delegate and grow. Today, many businesses are using heat transfers as a custom decorating solution for more orders than ever.

Why use heat transfers?

No matter what type of transfer you use, heat transfers have a myriad of benefits. This includes ease of use, the great cost to profitability ratios, the ability to print multicolor logos cost-efficiently, the ability to print on any garment location, and the fact that a transfer type for every fabric exists.

With the growth of heat press transfers, businesses are seeking advice on what transfers to use when. One way to make decisions easier is to understand the options and the economics.

Transfer technology types

Transfer technology can be grouped into five major buckets. They are:

Transfer technology can be grouped into five major buckets. They are:

- Plastisol screen printed transfers

- Digital screen printed transfers

- Vinyl cut transfers

- Print/cut digital transfers

- DTF or direct-to-film transfers — the newest member of the transfer scene

Vinyl transfers and print/cut transfers remain a great technology for producing in-house with a quick turnaround and for achieving special effects or special functions like dye blocking. However, when it comes to standard finish and functions, the other three technologies provide the solutions needed from an outsourced perspective.

Why outsource?

Outsourcing the production of your custom transfers is a viable method to scale a business, especially as the labor is tougher to find and retain. Heat press operators can be easily trained and press logos to garments with just a few hours of training. With that in mind, this helpful guide can help you decide easier.

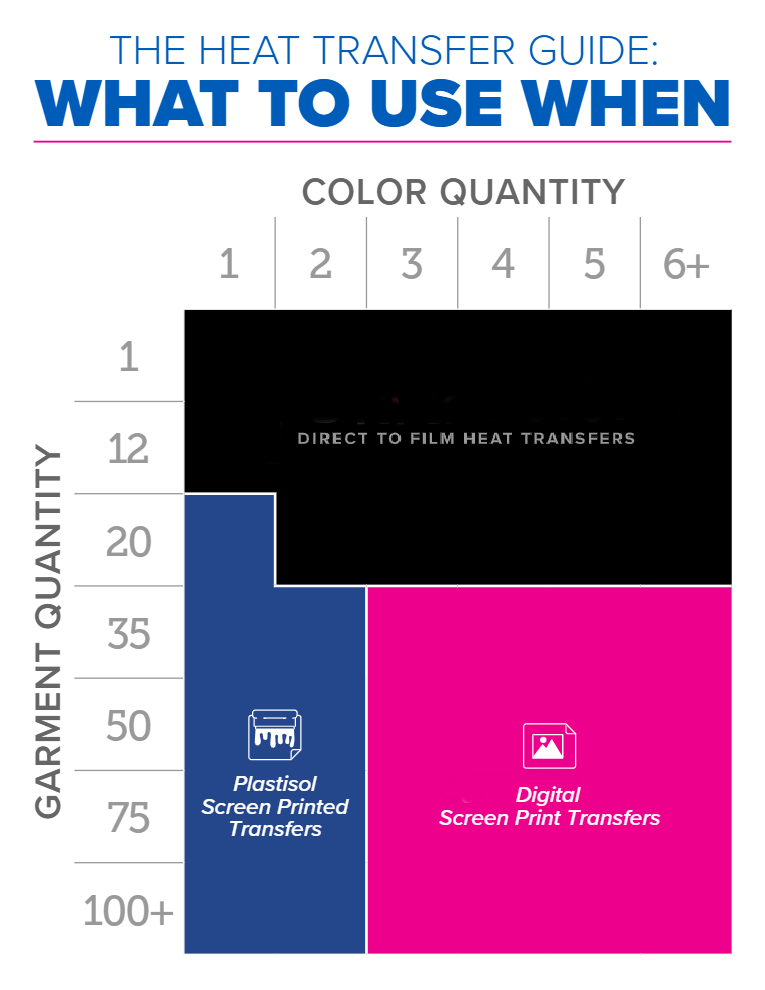

You can use the guide in these simple steps:

- How many colors are in your artwork? Find the corresponding number of colors on the x-axis.

- How many transfers do you need to order for the job? Find the corresponding number on the y-axis.

- Intersect the lines on the grid to get to the recommended transfer type.

Once you land on a transfer type, you can explore the choices available in that transfer technology. In most cases, there are a variety of product solutions within the transfer type. These choices span the next points of transfer choice like the look, feel, and finish.

You may find that you prefer some products for your clients over others. It is not uncommon for decorators to pay more for a transfer to drive simplicity and standardization into their business. Often, this simplification will save money and time when it comes to quoting, presenting your client choices, and running the product through production. It’s always a good idea to order some samples from each transfer type to evaluate them for your business.

Where DTF comes in

DTF, or direct-to-film, is a new technology that allows users to print designs onto special clear films using digital inks and a powder adhesive coating, which requires curing. After curing, you can then heat press the transfer design directly onto your garment.

Comparing DTF to other transfer types

When comparing DTF transfers to other transfer types, there are many differences. For example, DTF is different from using heat transfer vinyl because you don’t need to cut and weed your images. When compared to other types of digital transfers, DTF is usually more cost-effective. From a quality standpoint, DTF transfers have crisp, defined edges and you are able to print floating text and fine lines without a problem. They are a great option for small quantity orders and can be extremely user-friendly.

Many businesses are choosing direct-to-film for their multicolor logos as well as one or two color jobs. While the technology is in its infancy for systems, it is quite developed as a transfer service. Being able to reduce the complexity of choice that is driven by product limitations has opened up new opportunities for businesses.

DTF offers unlimited colors, fine detail, no outlines, and a low-temperature application, which makes DTF a promising, versatile technology that can solve a lot of logo needs.

You can print unlimited colors at no additional cost. They are perfect for gradients and shading, as well as extremely fine details with no outline. In addition, they can be heat pressed at lower temperatures, meaning you eliminate the dreaded scorch mark when heat pressing. You get a lightweight, soft hand result that adds no additional weight to the garment.

It is important to note that all DTF transfers are not created equal. There is quite a bit of variability in the market with feel, finish, and durability, so it is recommended that apparel decorators consider sampling from transfer suppliers to find the right fit.

![https://stock.adobe.com/images/for-all-printing-solutions-cropped-shot-of-male-worke[…]ng-heat-press-transfer-machine-for-printing-t-shirt/347629589](https://graphics-pro.com/wp-content/uploads/2022/02/AdobeStock_348692796-scaled.jpeg)