The process from sheet stock to finished award is a long one, but you need to understand the different types of acrylic available to create beautiful finished pieces.

Acrylic types

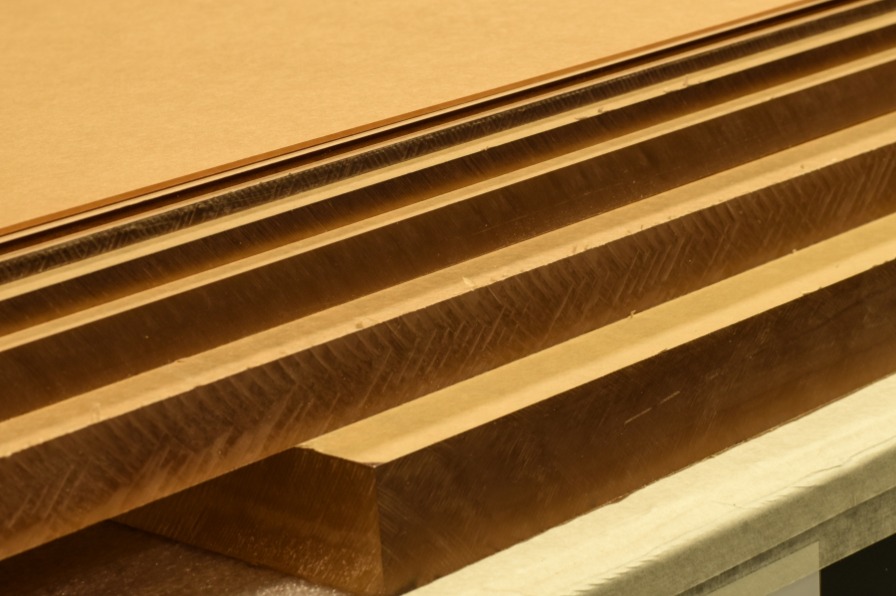

The first step in the process of creating an acrylic award is choosing the acrylic type. There are two main types of acrylic sheet stock: extruded and cast, also known as plexiglass.

Extruded acrylic is formed by pushing the material through forms while the acrylic is being formed. This process creates a flat sheet that holds tolerances well. In contrast, cast acrylic is formed by mixing chemicals and pouring them into molds. Since cast acrylic is poured into a mold to create the sheet, there are varying thicknesses to each sheet.

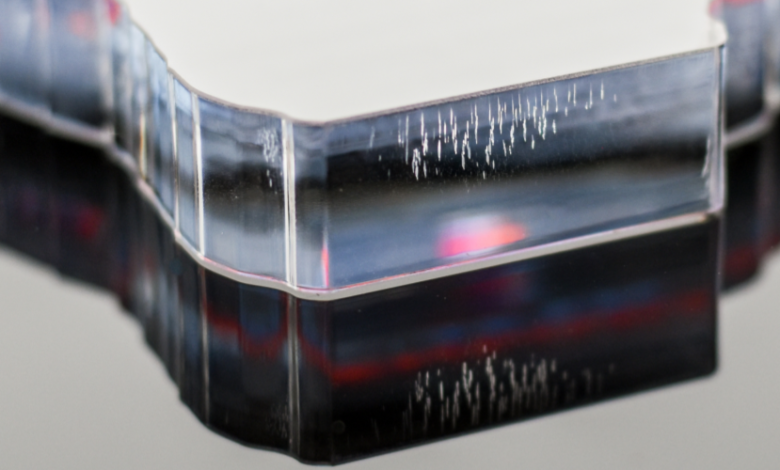

Extruded and cast acrylic produce vastly different results when laser cutting and engraving. When laser cutting, cast acrylic gives a beautiful flame-polished edge that is less prone to crazing (appearance of fine cracks on edges) than extruded acrylic.

Laser engraving cast and extruded acrylic also gives much different results. When laser engraved, cast acrylic yields a white engraving, whereas extruded acrylic gives a gray engraving. Cast acrylic produces flame-polished edges and vibrant white engravings, which make it ideal for award fabrication needs.

Acrylic thickness and colors

Cast acrylic is available in many different colors and thicknesses. Clear is the most popular choice, but colored acrylic can make an award pop. Most colors are available in thinner thicknesses, typically up to 1/4-inch thick.

Your equipment capabilities are also essential to understand before choosing the acrylic thickness for your project. Saws and CNC routers can cut acrylic but leave rough edges that require sanding and flame-polishing or buffing post-production. Lasers can cut and flame-polish in one step, which is a great way to save time and reduce the number of steps in your production. In general, the thicker the acrylic, the more powerful a laser you need to achieve smooth, flame-polished edges.

Learn more: Settings for Laser Cutting Acrylic