If we examine the actual DTG printing process, there are two primary components in making the shirt: pretreatment and ink.

Pretreatments are mostly water-based solutions that are applied to the garment and then heat set. For the most part, the components that comprise pretreatments are relatively inert after being cured (even though curing is not the best term to describe the drying of pretreatment). However, like all chemicals, you should never just dump liquid pretreatments down the drain. Always refer to the manufacturer and local authorities on how to dispose of waste materials properly.

One thing you can do is allow waste pretreatment to evaporate, leaving just the raw materials after the liquid is removed. This leftover material can be heat set (just like a shirt), which generally neutralizes the effects of the chemical components. This is why you should always try to use your pretreatment as efficiently as possible to minimize waste materials. Plus, one should never dump pretreatment into the water supply system as some pretreatments do have components that are not safe for aquatic life, which means it is not safe for humans either.

Another thing to keep in mind and look for is, is if your pretreatment solution is certified. There are many types of  certifications out there like Oeko-Tex, CPSIA (Consumer Product Safety Improvement Act), Prop 65, RoHS, etc.

certifications out there like Oeko-Tex, CPSIA (Consumer Product Safety Improvement Act), Prop 65, RoHS, etc.

As an example, Oeko-Tex Passport certification checks for chemicals, colorants, and accessories used in the manufacturing of textiles. The components in the product meet statutory requirements and are not harmful to human health. In other words, these certifications ensure that the products you are using are safe to use. Many of the tests show that the product does not contain lead, mercury, or levels of other chemicals deemed to be unsafe for humans to come into contact. Many manufacturers post on their websites the certifications their products have received. If you are unsure, contact the manufacturers directly to inquire as to the tests performed on their products.

The other component of DTG printing is the ink. Inks that DTG printers use are typically water-based pigmented ink sets. These inks are great for decorating shirts, and usually, there is next to no waste. However, the cleaning cycles of DTG printers do produce a cocktail of inks and cleaning type solutions. This DTG waste cocktail should not go down the drain in the liquid state.

In the current DTG world, you will typically have two categories of printers. One is a “bulk” ink delivery system where inks are filled in bottles or refillable cartridges. The other inks are typically sold in bags or plastic cartridges that are then consumed.

In bottle filled systems, though typically there is not much waste as the containers are refilled continuously, there will be times when you have waste ink, either from the bottles or the waste drain tube. So, what to do with it?

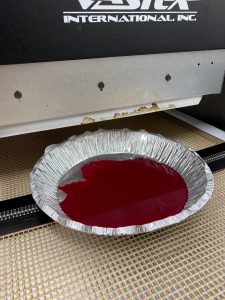

If you have access to a conveyor dryer, you could spread the ink out in a pie tin and dry it by running it through the dryer several times to cure it entirely. Typically, most inks are not a hazard in their cured (non-liquid) states. At that point, it is solid and can be disposed of properly.

If you have access to a conveyor dryer, you could spread the ink out in a pie tin and dry it by running it through the dryer several times to cure it entirely. Typically, most inks are not a hazard in their cured (non-liquid) states. At that point, it is solid and can be disposed of properly.

Ink in plastic cartridges is considered a one-time use type product. These often end up in landfills where the plastic that makes up the cartridges will not degrade over time. Many OEM and third-party businesses often offer a service where the used carts can be sent back, typically for free so that they can be appropriately recycled or cleaned out and re-used again. This helps reduce the environmental impact by reducing landfill waste.

As with any chemical or product, even though DTG products are typically more environmentally friendly, the best advice is to ask the manufacturer for the proper way to dispose of the materials and always follow local, state, and federal regulations.

Most people don’t give much thought to how their decorating processes can affect the environment around them. The great thing about DTG is that it is generally, and relatively “green” to begin with, but by implementing some of these suggestions, you can reduce your environmental impact even more without having to make significant changes in your shop.