Digital spot foiling has become a growing market for commercial printers. It allows printers to offer value-added embellishments on short-run, quick-turn production without the need for dyes and often without the need for much, if any, additional capital equipment purchases.

What is digital spot foiling?

Digital spot foiling — sometimes referred to as sleeking — is a technology that has existed for over 30 years. Originally developed in more of the craft market and generally done on home laser printers, this technology has evolved as commercial digital printing has grown over the last decade. With better digital printing equipment, new laminators specially configured for the process, and better foil formulations developed, the quality and consistency of this process have become commercially acceptable.

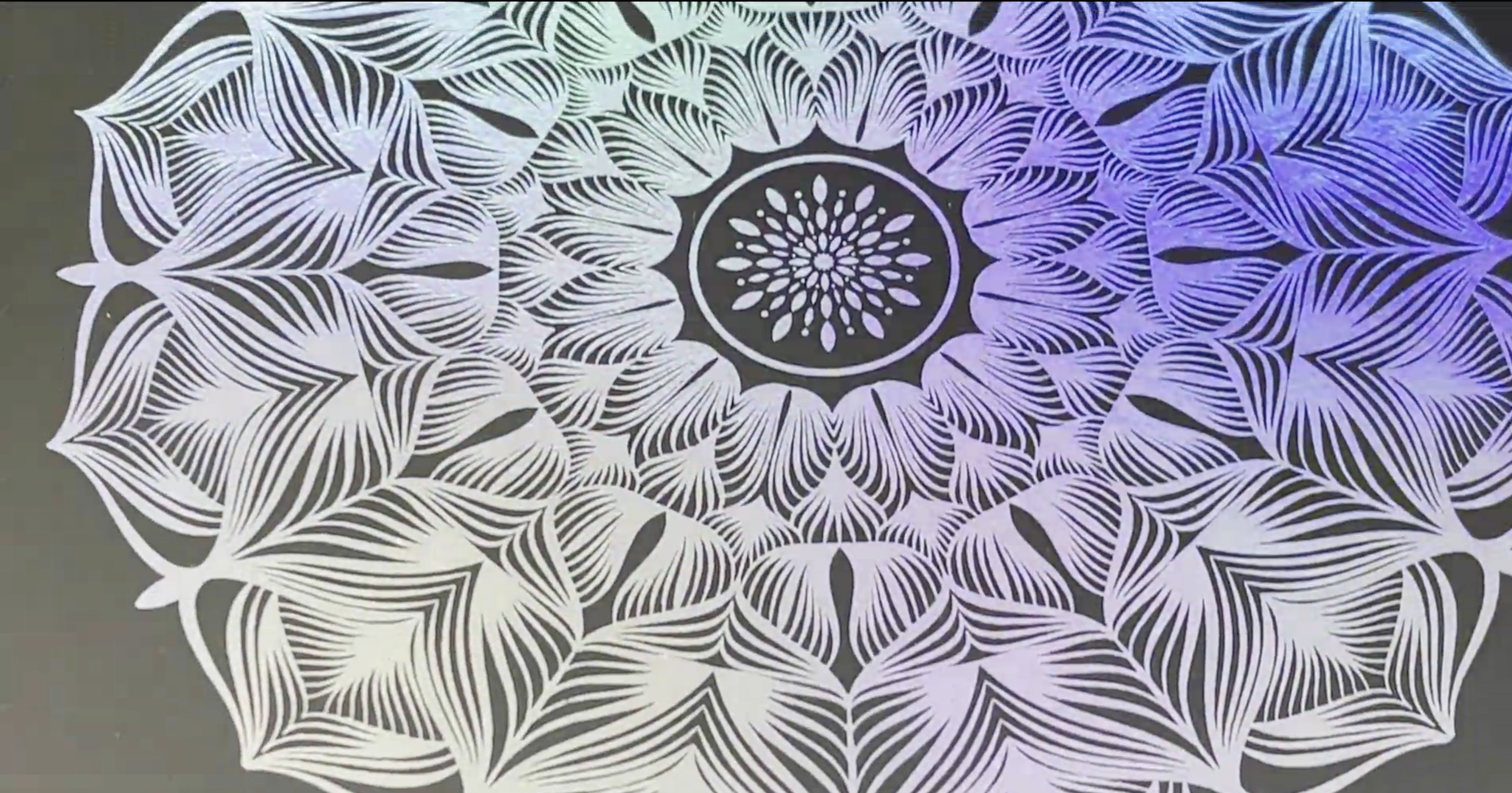

The basic technology is simple, lay down black toner where you want to foil, then run the print through a laminator and the toner acts as the bonding agent for the foil. Simply said, wherever you lay toner you will get foil.

Digital spot foil limitations

There are several processes for the application, the general limitations of the process are:

- The creativity of the designer

- The skill level of the printer operator

- The amount of labor you are willing to put into the process, or more importantly, can justifiably bill for

Digital spot foil methods

Below are the three common methods for digital spot foiling:

2-step process — The first and most simple application is foiling directly onto the stock. An example might be a wedding invite or name card.

3-step process — Similar to the 2-step process but after the foil is applied you can run the print back through the printer and add text or graphics in CMYK, the limitation here is that you cannot have your foil overlapping any CMYK print as registration would be extremely difficult.

4-step process — This is the process that will allow foil to be placed over the CMYK layer. In this process, the steps are reversed. Print the CYMK background layer, overlaminate with a printable soft touch or scuff-free matte laminate, then send the laminated print back through the printer to add the black toner where the foil is to be applied. Finally, run it through the laminator again to apply the foil.

Products

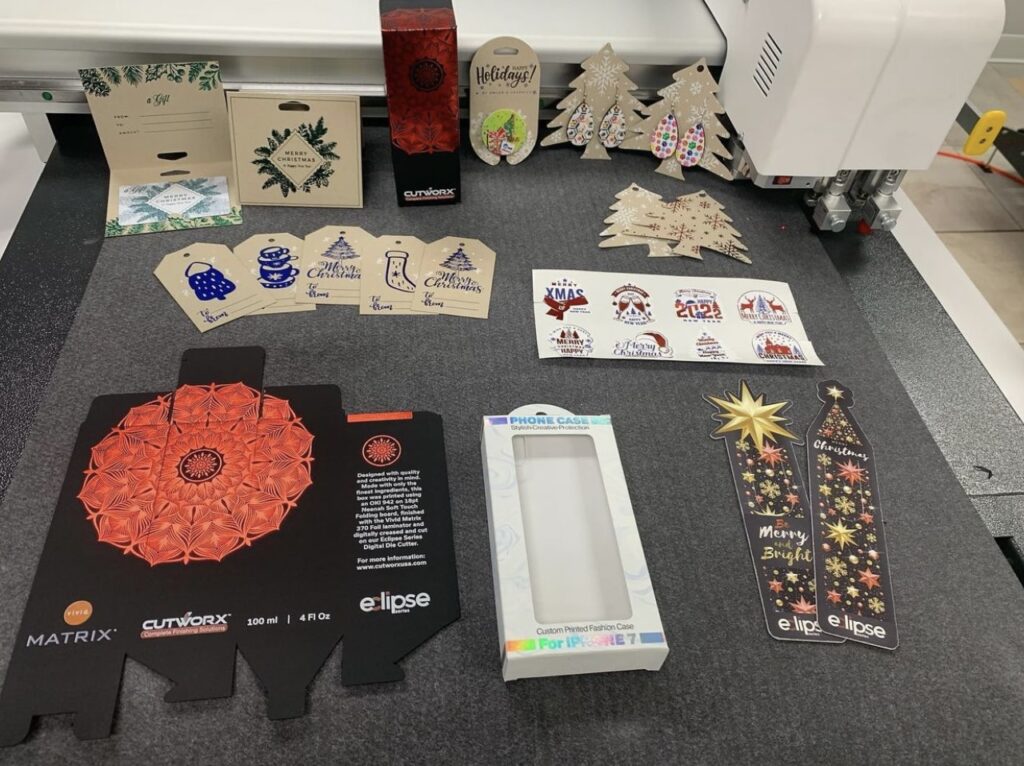

Some of the more popular products that lend themselves to foiling are:

- Book covers

- Business cards

- Invitations

- Holiday cards

- POP displays

- Direct mail