Cutting technology has stayed fairly consistent over the past few years. What has changed is the size of the machinery, the software, the level of automation, and the many tools and add-ons available.

Most sign shops can get by with a five-foot cutter because they typically cut sheets that measure 4′ X 8′ or 5′ X 10′, says Steve Sheetz, Safety Speed Manufacturing, a manufacturer of vertical panel saws and panel routers. “A lot of shops don’t have space to add multiple cutters.” He notes that as the reason why Safety Speed began offering a combination machine that has both a panel saw and a dust-free substrate cutter.

Shops that do a lot of printing or laminating can’t have a cutter that produces a lot of dust.

“Dust-free cutters are cutting using knife blades, scoring blades, and rotary wheel blades,” Sheetz adds. “Operators are pushing the blade through whatever substrate they are cutting. It is not motorized, so you are not throwing pieces of material and dust out while you cut. The limit on that is the strength of the operator. If you are making a lot of cuts, it can be pretty tiring.”

James Belcher, Graphtec America, states that his company’s cutters run the gamut from smaller hobby machines that work well for crafting and entry-level home-based businesses to intermediate level and high-volume production level cutters. The company’s cutters can cut from the thinnest to the thickest of substrates and come with operating software that enables shops to design and cut out an image, but it also keeps its equipment open architecture so that customers can use their existing software on Graphtec machines.

Graphtec plotters include a datalink barcode system and an upgraded vision system that allows print-and-cut from any printing device. “You can take the print from a desktop or rolltop printer of any size and can put it into the appropriate size cutter. It will read the registration marks and do a kiss cut, through cut, or perf cut,” Belcher explains. Graphtec’s cutters allow a shop to cut outside of the registration marks.

“It gives you the maximum yield you can get out of sheet or roll materials,” says Belcher. That could mean squeezing in an extra decal per row for maximum productivity.

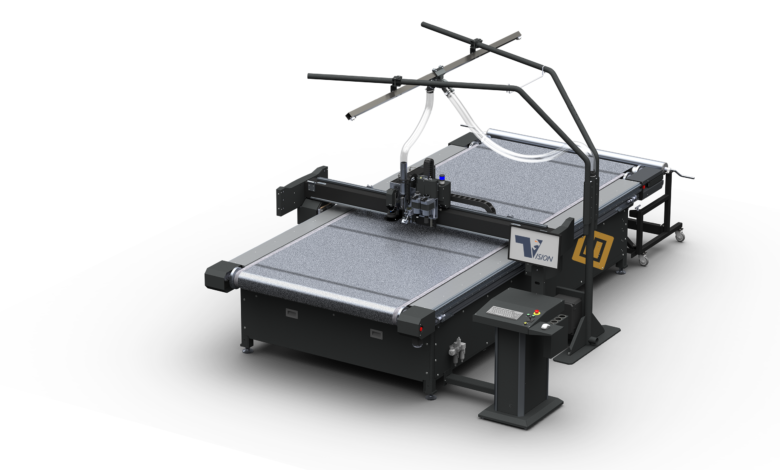

Beatrice Drury, Zund America, says the company’s flatbed multifunctional digital cutter has 30 or more tools to choose from, which is something that a shop should consider when looking to purchase this equipment. It can do kiss and through cuts, oscillating and rotary cutting, and routing. A laser module can also be added. There’s various punch, perforation, and creasing tools, and an inkjet tool for labeling.

In general, Justin Rinaldi, another member of the Safety Speed team, states that graphics producers looking to add a panel saw to their shop need to look at a few key things before making their choice: cut accuracy, maximum cross-cut and frame length, and how much space they have in their shop.

Mark Bibo, Gerber Technology, adds that cutters enable producers to take their shops to the next level, from hand cutting projects or outsourcing them to another shop to doing everything in-house.

Gerber’s MCT cutter has nine knife cutting tools so shops that want to start out using only one of the options, like milling, can expand into routing or laser cutting as they get more comfortable with the technology.

For example, Gerber’s automated drag and oscillating knives can be used to cut fabrics. Soft signage is the latest rage in the graphics industry and textiles can be knife cut or laser cut. “As long as a banner doesn’t have PVC in it, it can be laser cut,” Bibo explains. He adds that a new generation of PVC-free banner material is coming out, which will allow shops to laser cut flags and banners.